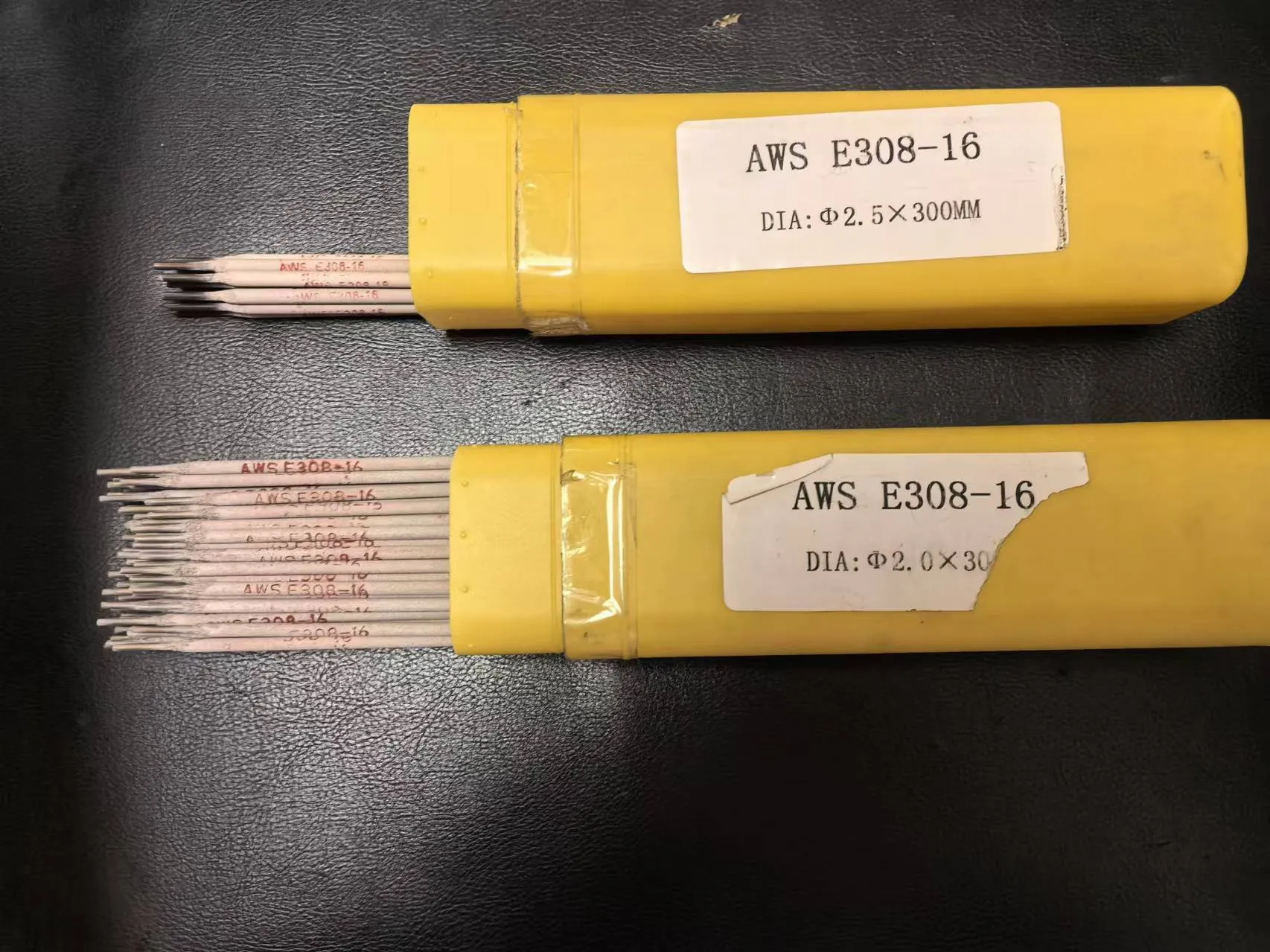

AWS EZ308 Cast Iron Welding Rods 2.0mm-5.0mm

2月 . 12, 2025 13:27

Choosing the right materials for your projects, particularly when it involves stainless steel stick rods, can be a decisive factor in determining the success and durability of your work. With extensive experience and expertise in metals and their applications, it is crucial to emphasize the unparalleled benefits of stainless steel stick rods for a wide range of industries, from construction to manufacturing.

From a manufacturing standpoint, stainless steel stick rods offer manufacturing advantages that are difficult for competitors to rival. Their high heat resistance allows for more efficient and precise welding practices. This quality is particularly appreciated in sectors where joint strength and durability are non-negotiable, enabling manufacturers to meet stringent safety standards without compromising on efficiency. Process engineers often advocate for stainless steel due to the consistency and reliability it provides during production. In the context of trustworthiness, the global reputation of stainless steel stick rods as a reliable backbone in countless infrastructures is well-documented. Numerous case studies from around the world illustrate the widespread adoption of stainless steel in critical infrastructure projects, reinforcing its status as a dependable material. Clients in sectors such as automotive, aerospace, and public transport have testified to the remarkable performance and safety enhancements achieved through the use of stainless steel components. Furthermore, investing in stainless steel stick rods signifies a commitment to quality and longevity. The exceptional metallurgical qualities ensure that structures withstand the test of time, reducing the frequency of replacements and further cutting costs in the long term. This not only establishes trust with stakeholders but also enhances project prestige, as the enduring resilience of stainless steel increases the reputational value of construction projects. In conclusion, stainless steel stick rods offer numerous advantages that make them an indispensable component in modern construction and manufacturing. Rooted in extensive research and practical application, their benefits are palpable across various industries. By choosing stainless steel, businesses not only adopt a material that meets and exceeds expectations but also align with a future that prioritizes durability, sustainability, and superior quality.

From a manufacturing standpoint, stainless steel stick rods offer manufacturing advantages that are difficult for competitors to rival. Their high heat resistance allows for more efficient and precise welding practices. This quality is particularly appreciated in sectors where joint strength and durability are non-negotiable, enabling manufacturers to meet stringent safety standards without compromising on efficiency. Process engineers often advocate for stainless steel due to the consistency and reliability it provides during production. In the context of trustworthiness, the global reputation of stainless steel stick rods as a reliable backbone in countless infrastructures is well-documented. Numerous case studies from around the world illustrate the widespread adoption of stainless steel in critical infrastructure projects, reinforcing its status as a dependable material. Clients in sectors such as automotive, aerospace, and public transport have testified to the remarkable performance and safety enhancements achieved through the use of stainless steel components. Furthermore, investing in stainless steel stick rods signifies a commitment to quality and longevity. The exceptional metallurgical qualities ensure that structures withstand the test of time, reducing the frequency of replacements and further cutting costs in the long term. This not only establishes trust with stakeholders but also enhances project prestige, as the enduring resilience of stainless steel increases the reputational value of construction projects. In conclusion, stainless steel stick rods offer numerous advantages that make them an indispensable component in modern construction and manufacturing. Rooted in extensive research and practical application, their benefits are palpable across various industries. By choosing stainless steel, businesses not only adopt a material that meets and exceeds expectations but also align with a future that prioritizes durability, sustainability, and superior quality.

Related Video

Copyright © 2025 Dingzhou Jinlong Metal Production Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy