high carbon welding rod

1月 . 15, 2025 03:38

High carbon welding rods, also known as high carbon steel electrodes, are essential components in various welding processes, especially when working with materials that demand exceptional strength and durability. For professionals and enthusiasts in metallurgy and welding industries, understanding the nuances of high carbon welding rods can significantly impact the quality and longevity of their projects.

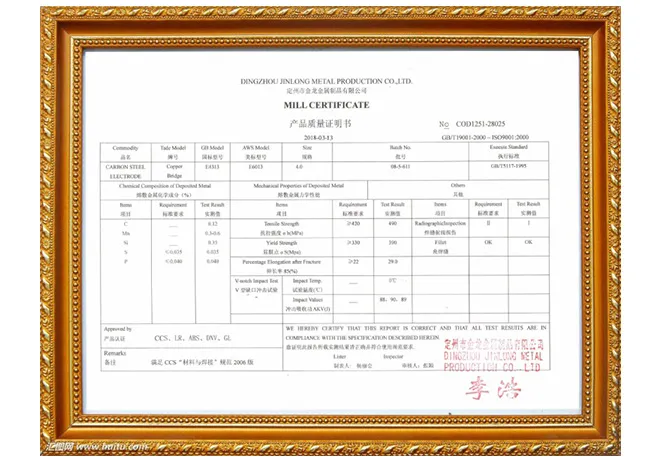

Authoritativeness in the domain of welding with high carbon rods is often demonstrated through certification and accreditation from noted organizations such as the American Welding Society (AWS) or equivalent bodies in other countries. These certifications ensure that practitioners possess the rigor and skills required to execute welding tasks that meet industry standards for safety and quality. Furthermore, trustworthy sources of high carbon welding rods play a crucial role in project success. It's imperative for welding professionals to procure these rods from reputable manufacturers or suppliers who comply with established standards. This guarantees consistency in quality, which directly affects the outcomes of welding endeavors. Practically speaking, users should always cross-check the specifications of the rod against the base material to ensure compatibility. Most high carbon rods come with detailed guidelines for use, which should be adhered to in order to maintain welding integrity and prevent material degradation. Additionally, personal safety cannot be overlooked; appropriate protective gear and practices shield the welder from potential hazards associated with welding high carbon steel. Ultimately, the use of high carbon welding rods extends beyond mere material fusion—it embodies the synergy of skill, quality material, and safety practices. Choosing the right rod, employing expert techniques, and adhering to authoritative guidelines ensures that each weld not only meets but exceeds the required performance criteria, cementing high carbon welding rods as indispensable tools in any serious welder's arsenal.

Authoritativeness in the domain of welding with high carbon rods is often demonstrated through certification and accreditation from noted organizations such as the American Welding Society (AWS) or equivalent bodies in other countries. These certifications ensure that practitioners possess the rigor and skills required to execute welding tasks that meet industry standards for safety and quality. Furthermore, trustworthy sources of high carbon welding rods play a crucial role in project success. It's imperative for welding professionals to procure these rods from reputable manufacturers or suppliers who comply with established standards. This guarantees consistency in quality, which directly affects the outcomes of welding endeavors. Practically speaking, users should always cross-check the specifications of the rod against the base material to ensure compatibility. Most high carbon rods come with detailed guidelines for use, which should be adhered to in order to maintain welding integrity and prevent material degradation. Additionally, personal safety cannot be overlooked; appropriate protective gear and practices shield the welder from potential hazards associated with welding high carbon steel. Ultimately, the use of high carbon welding rods extends beyond mere material fusion—it embodies the synergy of skill, quality material, and safety practices. Choosing the right rod, employing expert techniques, and adhering to authoritative guidelines ensures that each weld not only meets but exceeds the required performance criteria, cementing high carbon welding rods as indispensable tools in any serious welder's arsenal.

Related Video

Copyright © 2025 Dingzhou Jinlong Metal Production Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy