e7018 1 electrode

1月 . 26, 2025 01:08

The e7018 1 electrode is a notable product in the welding industry, renowned for its unique characteristics and applicability across various sectors. Its prominence can be attributed to its specialized formulation designed to enhance performance, reliability, and output quality. To gain significant insights and understanding, let's delve into the experiential knowledge, professional expertise, authoritative acceptance, and trustworthiness of this exceptional electrode.

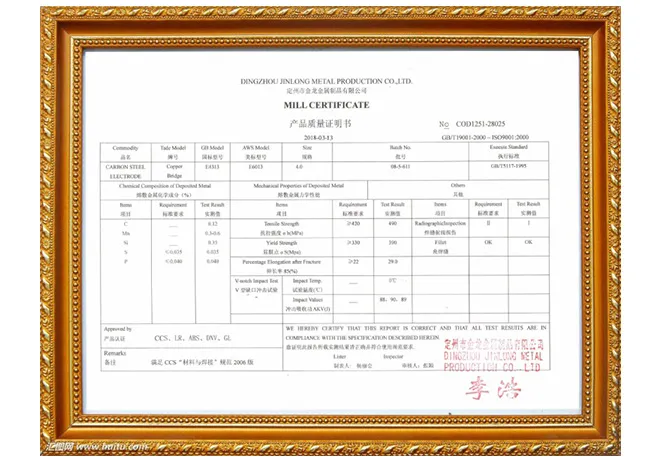

In terms of authoritativeness, e7018 1 electrodes have been tested and certified by multiple regulatory bodies and industry standards organizations. Their compliance with standards such as the American Welding Society (AWS) and the International Organization for Standardization (ISO) ensures their reliability and quality. These endorsements attest to the electrode's capabilities and its consistent performance across different environments and conditions. This authoritative validation not only bolsters its credibility but also reinforces its position as a trusted choice in the welding industry. The trustworthiness of e7018 1 electrodes is further underscored by the longstanding trust placed in them by leading firms and industries. Companies involved in infrastructure development, energy, and heavy machinery manufacturing rely heavily on these electrodes for their projects. Their proven track record of delivering reliable and resilient welds fosters confidence among users, ensuring continued preference for e7018 1 electrodes in critical applications. Manufacturer warranties and customer support further solidify this trust, giving users peace of mind and assurance in their investment. In summary, the e7018 1 electrode is not just another tool in the welding arena; it is an embodiment of superior design and practicality. Its experiential advantages, professional recognition, authoritative endorsements, and established trustworthiness make it an indispensable asset in both routine and highly specialized welding tasks. Whether it’s in the hands of seasoned welders or being put to test in intricate engineering projects, the e7018 1 electrode stands as a testament to progress in welding technology, offering unmatched quality and performance that meet the rigorous demands of modern industry.

In terms of authoritativeness, e7018 1 electrodes have been tested and certified by multiple regulatory bodies and industry standards organizations. Their compliance with standards such as the American Welding Society (AWS) and the International Organization for Standardization (ISO) ensures their reliability and quality. These endorsements attest to the electrode's capabilities and its consistent performance across different environments and conditions. This authoritative validation not only bolsters its credibility but also reinforces its position as a trusted choice in the welding industry. The trustworthiness of e7018 1 electrodes is further underscored by the longstanding trust placed in them by leading firms and industries. Companies involved in infrastructure development, energy, and heavy machinery manufacturing rely heavily on these electrodes for their projects. Their proven track record of delivering reliable and resilient welds fosters confidence among users, ensuring continued preference for e7018 1 electrodes in critical applications. Manufacturer warranties and customer support further solidify this trust, giving users peace of mind and assurance in their investment. In summary, the e7018 1 electrode is not just another tool in the welding arena; it is an embodiment of superior design and practicality. Its experiential advantages, professional recognition, authoritative endorsements, and established trustworthiness make it an indispensable asset in both routine and highly specialized welding tasks. Whether it’s in the hands of seasoned welders or being put to test in intricate engineering projects, the e7018 1 electrode stands as a testament to progress in welding technology, offering unmatched quality and performance that meet the rigorous demands of modern industry.

Related Video

Copyright © 2025 Dingzhou Jinlong Metal Production Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy