cast iron tig filler rod

2月 . 18, 2025 06:49

In the world of metalworking, choosing the right materials can significantly impact the quality and longevity of your projects. Cast iron filler rods, particularly those used in Tungsten Inert Gas (TIG) welding, are a subject of considerable interest and expertise. For professionals committed to delivering exceptional workmanship, understanding the nuances of cast iron filler rods for TIG welding is not just beneficial—it's essential.

Casting an authoritative presence in the field requires commitment to continuous learning and sharing knowledge gained from real-world applications. Practitioners are encouraged to stay updated with technological advancements in filler materials and welding techniques. Materials engineers and welding experts frequently publish studies and case reviews showcasing innovative approaches to overcome common issues encountered with cast iron. The use of detailed documentation and adherence to welding standards not only enhances credibility but also serves as a valuable resource for those seeking knowledge. Trustworthiness, a cornerstone of any successful craft or profession, is built through consistent results and transparency. For a welder, establishing trust with clients involves demonstrating an understanding of both the material and the methodology. This could include providing clear explanations of the processes involved, expected outcomes, and potential challenges. Transparency in selecting the appropriate cast iron filler rod, be it ERNiFe-CI, ERNi55, or any other suitable variant, assures clients of a welder's commitment to quality and durability. Thus, the choice of cast iron filler rods for TIG welding integrates experience, expertise, authority, and trust. Through meticulous selection and application, welding professionals not only enhance the structural viability of cast iron components but also uphold the highest standards of craftsmanship. The ability to navigate the complexities of cast iron welding reflects a deep-seated commitment to the trade—one that values knowledge as much as skill, and innovation as much as tradition. Continuing to invest in one's craft by exploring developments and gaining practical insights into cast iron filler rods serves not only the immediate needs of projects but also contributes to the broader knowledge pool within the industry. For any metalworker or welder aiming to deliver flawless results, understanding and applying these principles is not just advisable—it's imperative.

Casting an authoritative presence in the field requires commitment to continuous learning and sharing knowledge gained from real-world applications. Practitioners are encouraged to stay updated with technological advancements in filler materials and welding techniques. Materials engineers and welding experts frequently publish studies and case reviews showcasing innovative approaches to overcome common issues encountered with cast iron. The use of detailed documentation and adherence to welding standards not only enhances credibility but also serves as a valuable resource for those seeking knowledge. Trustworthiness, a cornerstone of any successful craft or profession, is built through consistent results and transparency. For a welder, establishing trust with clients involves demonstrating an understanding of both the material and the methodology. This could include providing clear explanations of the processes involved, expected outcomes, and potential challenges. Transparency in selecting the appropriate cast iron filler rod, be it ERNiFe-CI, ERNi55, or any other suitable variant, assures clients of a welder's commitment to quality and durability. Thus, the choice of cast iron filler rods for TIG welding integrates experience, expertise, authority, and trust. Through meticulous selection and application, welding professionals not only enhance the structural viability of cast iron components but also uphold the highest standards of craftsmanship. The ability to navigate the complexities of cast iron welding reflects a deep-seated commitment to the trade—one that values knowledge as much as skill, and innovation as much as tradition. Continuing to invest in one's craft by exploring developments and gaining practical insights into cast iron filler rods serves not only the immediate needs of projects but also contributes to the broader knowledge pool within the industry. For any metalworker or welder aiming to deliver flawless results, understanding and applying these principles is not just advisable—it's imperative.

Related Video

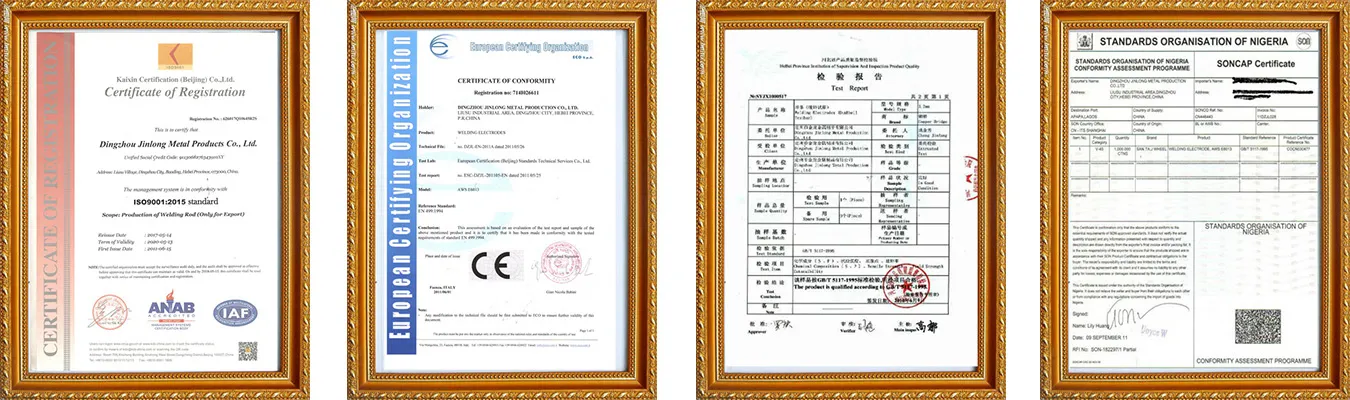

Copyright © 2025 Dingzhou Jinlong Metal Production Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy