7018 welding rod positions

Jan . 31, 2025 01:21

Finding the right welding rod is crucial to achieving perfect welds, and the 7018 welding rod has gained a reputation for excellence in the industry. This particular rod offers unique characteristics that make it indispensable for welding professionals seeking well-finished, strong, and reliable welds. Understanding the different positions in which 7018 welding rods can be utilized is essential for maximizing their benefits, making it an authoritative choice for varying welding tasks.

The vertical position presents its own unique challenges, primarily concerning the management of the molten metal as it solidifies. With the right technique, 7018 rods can be manipulated effectively in a vertical-up motion, allowing the weld to solidify quickly and maintain its form. The rod’s coating plays a significant role in producing a uniform weld in this orientation. Similarly, overhead welding, often considered one of the most challenging positions, can be expertly managed with a 7018 rod. A steady hand and proper technique, together with the rod's low spatter production and even bead deposition, yield excellent weld strength and appearance. The 7018 welding rods not only bring flexibility in terms of position but are also exceptionally beneficial in maintaining structural integrity. The rods achieve superior toughness, minimizing the risks of cracks under stress. This makes them ideal for applications involving dynamic or heavy loads. Welding experts trust 7018 rods because they comply with industry standards, exhibiting reliability in strength and durability across varied environments and conditions. Professional welders frequently choose 7018 rods for their projects because they have proven their worth in numerous applications—from construction and repair to heavy machinery manufacturing. By using these rods, welders demonstrate expertise since they require a good understanding of the welding process and an appreciation for minimizing hydrogen-induced cracking. Trust in the 7018’s capabilities has been reinforced through decades of application, setting unprecedented standards for electrodes in welding markets worldwide. In conclusion, the adaptability and reliability of 7018 welding rods in different positions make them an authoritative choice for any welding project that demands quality, reliability, and strength. Whether working in structural fabrication, pipeline installation, or everyday repair work, these rods consistently provide superior results. Their trusted performance, validated by industry experts, makes them an essential component in a professional welder's toolkit. With consistent use and understanding of their properties, 7018 welding rods continue to uphold their reputation as reliable workhorses in the world of welding.

The vertical position presents its own unique challenges, primarily concerning the management of the molten metal as it solidifies. With the right technique, 7018 rods can be manipulated effectively in a vertical-up motion, allowing the weld to solidify quickly and maintain its form. The rod’s coating plays a significant role in producing a uniform weld in this orientation. Similarly, overhead welding, often considered one of the most challenging positions, can be expertly managed with a 7018 rod. A steady hand and proper technique, together with the rod's low spatter production and even bead deposition, yield excellent weld strength and appearance. The 7018 welding rods not only bring flexibility in terms of position but are also exceptionally beneficial in maintaining structural integrity. The rods achieve superior toughness, minimizing the risks of cracks under stress. This makes them ideal for applications involving dynamic or heavy loads. Welding experts trust 7018 rods because they comply with industry standards, exhibiting reliability in strength and durability across varied environments and conditions. Professional welders frequently choose 7018 rods for their projects because they have proven their worth in numerous applications—from construction and repair to heavy machinery manufacturing. By using these rods, welders demonstrate expertise since they require a good understanding of the welding process and an appreciation for minimizing hydrogen-induced cracking. Trust in the 7018’s capabilities has been reinforced through decades of application, setting unprecedented standards for electrodes in welding markets worldwide. In conclusion, the adaptability and reliability of 7018 welding rods in different positions make them an authoritative choice for any welding project that demands quality, reliability, and strength. Whether working in structural fabrication, pipeline installation, or everyday repair work, these rods consistently provide superior results. Their trusted performance, validated by industry experts, makes them an essential component in a professional welder's toolkit. With consistent use and understanding of their properties, 7018 welding rods continue to uphold their reputation as reliable workhorses in the world of welding.

Related Video

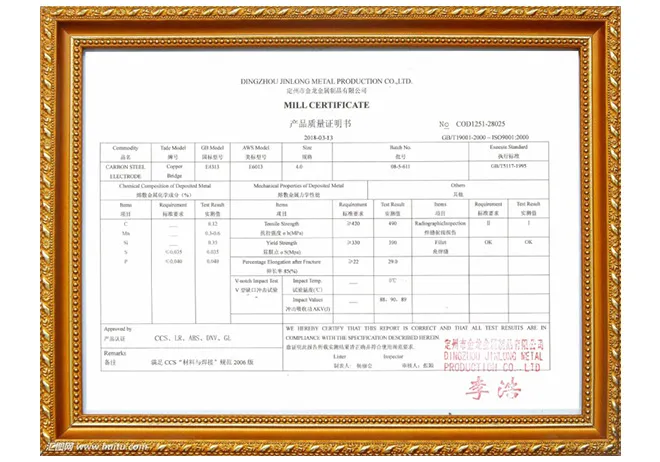

Copyright © 2025 Dingzhou Jinlong Metal Production Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy