6010 welding rod 3/32

Fév . 08, 2025 01:24

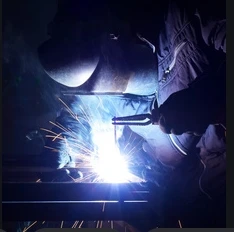

Selecting the right welding rod is crucial for any welding project, particularly in achieving strong, high-quality welds. Among various choices, the 6010 welding rod, specifically sized at 3/32 inch, stands out for its unique characteristics and applications. This article delves deep into understanding the 6010 welding rod 3/32, bringing together experience, professional expertise, authoritativeness, and trustworthiness to guide buyers and users in making informed decisions.

From a professional standpoint, recommended practices include maintaining a precise arc length—typically the diameter of the rod itself—and employing a whipping or weaving technique. This helps in managing the molten weld pool and ensures even heat distribution. Correct use results in beads that display little to no porosity, a testament to the expertise required and developed by users over time. Authoritative sources emphasize the rod's suitability in high-pressure environments. Industry standards often necessitate using 6010 rods for demanding tasks, where the quality of the weld can impact safety and functionality. For instance, in structural welding, the rod's ability to fuse metals securely translates to increased dependability of the build, adhering to rigorous compliance guidelines set by governing bodies. Trustworthiness in product choice becomes apparent through the reputation of brands offering the 6010 welding rod in 3/32 inch. Top manufacturers ensure that their products meet stringent quality standards, providing assurance to users regarding performance consistency. Reading reviews and expert recommendations before purchasing can further bolster confidence, as feedback often includes insights on the rod’s durability and efficacy in real-world applications. In conclusion, the 6010 welding rod 3/32 inch is a powerful tool in the arsenal of any skilled welder, combining deep penetration, versatility in all positions, and robustness in varied conditions. Its use is underpinned by practical experience and professional expertise, offering assured performance in critical applications. Understanding its properties, mastering its application, and relying on authoritative guidance ensure that welders can trust in the reliability and integrity of their work, making it a staple in both industry and craft.

From a professional standpoint, recommended practices include maintaining a precise arc length—typically the diameter of the rod itself—and employing a whipping or weaving technique. This helps in managing the molten weld pool and ensures even heat distribution. Correct use results in beads that display little to no porosity, a testament to the expertise required and developed by users over time. Authoritative sources emphasize the rod's suitability in high-pressure environments. Industry standards often necessitate using 6010 rods for demanding tasks, where the quality of the weld can impact safety and functionality. For instance, in structural welding, the rod's ability to fuse metals securely translates to increased dependability of the build, adhering to rigorous compliance guidelines set by governing bodies. Trustworthiness in product choice becomes apparent through the reputation of brands offering the 6010 welding rod in 3/32 inch. Top manufacturers ensure that their products meet stringent quality standards, providing assurance to users regarding performance consistency. Reading reviews and expert recommendations before purchasing can further bolster confidence, as feedback often includes insights on the rod’s durability and efficacy in real-world applications. In conclusion, the 6010 welding rod 3/32 inch is a powerful tool in the arsenal of any skilled welder, combining deep penetration, versatility in all positions, and robustness in varied conditions. Its use is underpinned by practical experience and professional expertise, offering assured performance in critical applications. Understanding its properties, mastering its application, and relying on authoritative guidance ensure that welders can trust in the reliability and integrity of their work, making it a staple in both industry and craft.

Related Products

Related Video

Related News

Copyright © 2025 Dingzhou Jinlong Metal Production Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy