7018 electrode uses

জানু. . 30, 2025 05:43

Electrodes have revolutionized various sectors with their versatile applications and unmatched efficiency. The model 7018 electrode, in particular, stands out in the realm of welding, offering unparalleled benefits for both professionals and hobbyists in construction, automotive repairs, and heavy-duty manufacturing. Understanding the broad applications and the specifics of using 7018 electrodes can significantly enhance project outcomes, ensuring both durability and precision.

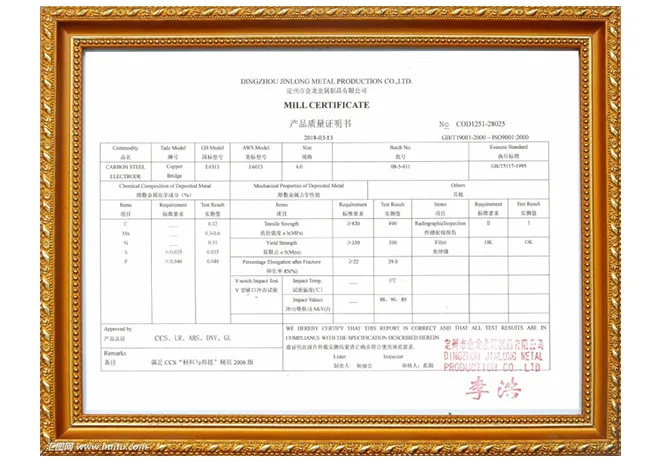

The authoritativeness of the 7018 electrode's applications is backed by numerous certifications and industry standards, including the AWS A5.1 designation for carbon steel electrodes. These certifications corroborate its performance capabilities, providing assurance to users that they are employing a product that meets rigorous quality and safety benchmarks. Industry professionals trust the 7018 electrode for critical projects precisely because of its proven track record and industry endorsements. Trustworthiness in using 7018 electrodes is also supported by real-world testimonials from users who consistently achieve superior outcomes. Welders report fewer post-weld treatments and quicker project turnovers, attributing these efficiencies to the electrode's predictable and stable performance. This consistency not only boosts productivity but also enhances the confidence of the stakeholders in the project's long-term viability. The 7018 electrode is not without challenges; maintaining the correct angle and travel speed is crucial to prevent defects such as slag inclusions or porosity. Training and practical experience are invaluable for mastering these techniques. Welding schools and professional courses often include modules dedicated to the effective use of 7018 electrodes, emphasizing their importance in the welding industry. Overall, the 7018 electrode remains a pillar in welding operations across diverse industries. Its user-friendly nature, combined with superior mechanical properties, makes it an indispensable tool for achieving demanding standards and robust welds. For large-scale infrastructure projects or small personal endeavors, this electrode delivers exceptional reliability and performance, underscoring its reputation as a staple in any welder's toolkit. With ongoing advancements in electrode technology, the future promises even more innovations that will build on the established success of the 7018 electrode, continuing its legacy of excellence and trust.

The authoritativeness of the 7018 electrode's applications is backed by numerous certifications and industry standards, including the AWS A5.1 designation for carbon steel electrodes. These certifications corroborate its performance capabilities, providing assurance to users that they are employing a product that meets rigorous quality and safety benchmarks. Industry professionals trust the 7018 electrode for critical projects precisely because of its proven track record and industry endorsements. Trustworthiness in using 7018 electrodes is also supported by real-world testimonials from users who consistently achieve superior outcomes. Welders report fewer post-weld treatments and quicker project turnovers, attributing these efficiencies to the electrode's predictable and stable performance. This consistency not only boosts productivity but also enhances the confidence of the stakeholders in the project's long-term viability. The 7018 electrode is not without challenges; maintaining the correct angle and travel speed is crucial to prevent defects such as slag inclusions or porosity. Training and practical experience are invaluable for mastering these techniques. Welding schools and professional courses often include modules dedicated to the effective use of 7018 electrodes, emphasizing their importance in the welding industry. Overall, the 7018 electrode remains a pillar in welding operations across diverse industries. Its user-friendly nature, combined with superior mechanical properties, makes it an indispensable tool for achieving demanding standards and robust welds. For large-scale infrastructure projects or small personal endeavors, this electrode delivers exceptional reliability and performance, underscoring its reputation as a staple in any welder's toolkit. With ongoing advancements in electrode technology, the future promises even more innovations that will build on the established success of the 7018 electrode, continuing its legacy of excellence and trust.

Related Products

Related Video

Related News

Copyright © 2025 Dingzhou Jinlong Metal Production Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy