Oxidation-Corrosion-Resistant Cast Iron Welding Alloy Nife-1

ఫిబ్ర . 18, 2025 02:22

Ferro nickel welding rods have long been an essential tool in various industrial applications, renowned for their unique properties and capabilities. These welding rods play a crucial role in industries ranging from construction to shipbuilding, promising durability and strength in every weld. By delving into the experience of using these rods, their engineering superiority, authority-backed facts, and trusted reliability, one can understand why they stand out in the realm of welding solutions.

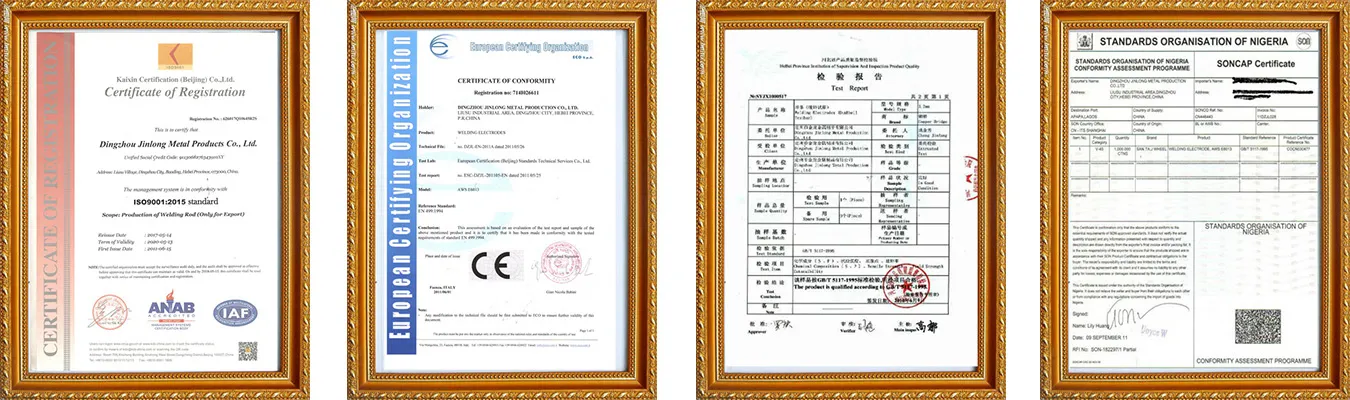

Trustworthiness and Reliability The trustworthiness of ferro nickel welding rods is built upon a foundation of proven performance over time. They are often the go-to choice for infrastructure projects that require long-term durability and integrity. Real-world case studies demonstrate their performance in high-stakes scenarios, such as underwater pipelines and nuclear facilities, verifying their reliability. Users trust these rods not just for their immediate performance but for the assurance they provide in maintaining structural integrity for years, if not decades, following application. End-Use Versatility One of the standout features of ferro nickel welding rods is their versatility across various applications. From high-tensile steel structures to nickel-chrome alloys, these rods provide a stable solution for diverse welding requirements. Industries including aviation, automotive, and offshore drilling have benefitted from the adaptability of ferro nickel rods, which can be used to join high-strength steels and cast irons effectively. This adaptability minimizes the need for multiple types of rods, simplifying inventory management and ensuring that welders are always prepared with the right tool for the job. Optimal Performance in Challenging Conditions Ferro nickel welding rods are specifically designed to perform under challenging conditions such as sub-zero temperatures and high thermal stress. Their superior thermal conductivity helps maintain weld consistency, an attribute highly appreciated in industries exposed to varying ambient conditions. Such performance capabilities not only support structural integrity but also enhance safety standards, reducing the likelihood of weld failure which could lead to catastrophic consequences. In conclusion, ferro nickel welding rods represent an intersection of advanced metallurgy, engineering expertise, and trusted reliability. Their consistent performance, backed by industry certifications, makes them indispensable for projects requiring robust and durable welds. As industries continue to evolve, the demand for high-quality, dependable welding solutions like ferro nickel rods is likely to grow, solidifying their place in the future of welding technology. For professionals seeking both innovation and trust, these rods provide a solution that meets and exceeds expectations in every regard.

Trustworthiness and Reliability The trustworthiness of ferro nickel welding rods is built upon a foundation of proven performance over time. They are often the go-to choice for infrastructure projects that require long-term durability and integrity. Real-world case studies demonstrate their performance in high-stakes scenarios, such as underwater pipelines and nuclear facilities, verifying their reliability. Users trust these rods not just for their immediate performance but for the assurance they provide in maintaining structural integrity for years, if not decades, following application. End-Use Versatility One of the standout features of ferro nickel welding rods is their versatility across various applications. From high-tensile steel structures to nickel-chrome alloys, these rods provide a stable solution for diverse welding requirements. Industries including aviation, automotive, and offshore drilling have benefitted from the adaptability of ferro nickel rods, which can be used to join high-strength steels and cast irons effectively. This adaptability minimizes the need for multiple types of rods, simplifying inventory management and ensuring that welders are always prepared with the right tool for the job. Optimal Performance in Challenging Conditions Ferro nickel welding rods are specifically designed to perform under challenging conditions such as sub-zero temperatures and high thermal stress. Their superior thermal conductivity helps maintain weld consistency, an attribute highly appreciated in industries exposed to varying ambient conditions. Such performance capabilities not only support structural integrity but also enhance safety standards, reducing the likelihood of weld failure which could lead to catastrophic consequences. In conclusion, ferro nickel welding rods represent an intersection of advanced metallurgy, engineering expertise, and trusted reliability. Their consistent performance, backed by industry certifications, makes them indispensable for projects requiring robust and durable welds. As industries continue to evolve, the demand for high-quality, dependable welding solutions like ferro nickel rods is likely to grow, solidifying their place in the future of welding technology. For professionals seeking both innovation and trust, these rods provide a solution that meets and exceeds expectations in every regard.

Related Video

Copyright © 2025 Dingzhou Jinlong Metal Production Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy