cast iron filler rod

ఫిబ్ర . 18, 2025 05:19

The utility and versatility of cast iron filler rods make them indispensable in a variety of welding applications, particularly when working with cast iron materials. Known for their durability and strength, these rods facilitate strong bonds and seamless repairs in an array of industrial and domestic settings.

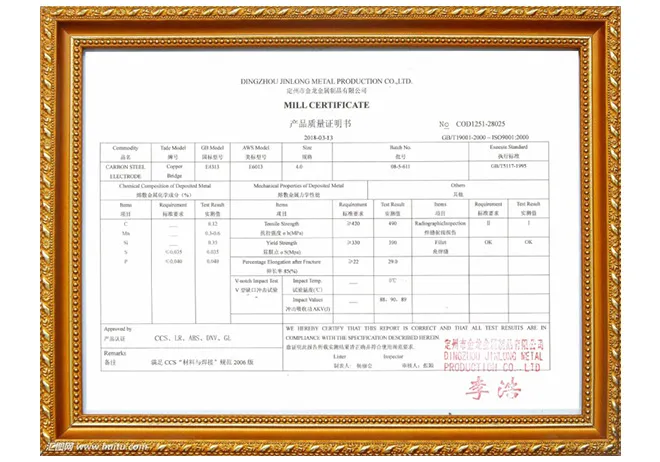

When it comes to authoritativeness, it is crucial to source these rods from reputable suppliers known for their manufacturing precision and material integrity. Trusted brands adhere to stringent quality standards and often subject their products to rigorous testing to ensure compatibility and performance. Feedback from seasoned professionals consistently highlights the importance of investigating the manufacturer’s credentials and the technological specifications of the filler rods before committing to a purchase. Buyers are advised to consult technical data sheets and user testimonials to ensure they are investing in a product that will perform reliably under the stress of repair or fabrication work. For welders who are just beginning to explore the use of cast iron filler rods, it’s beneficial to seek insights from experienced professionals or take part in workshops that offer practical, hands-on experience. This not only enhances trustworthiness in the skills being acquired but also fosters a deeper understanding of the subtle nuances involved in cast iron welding. Industry forums, trade-specific publications, and workshops can be valuable resources for learning the latest techniques and understanding the future trends impacting the use of these specialized fillers. In conclusion, the smart selection and application of cast iron filler rods are vital to maximizing structural integrity and achieving superior performance in weldments. Whether working on automotive restoration, industrial machinery repairs, or creating custom iron artworks, employing the correct filler rod and technique is paramount. As the industry continues to evolve, staying informed and continuously upgrading skills ensure that professionals remain at the forefront of innovation, providing effective solutions to challenging welding scenarios.

When it comes to authoritativeness, it is crucial to source these rods from reputable suppliers known for their manufacturing precision and material integrity. Trusted brands adhere to stringent quality standards and often subject their products to rigorous testing to ensure compatibility and performance. Feedback from seasoned professionals consistently highlights the importance of investigating the manufacturer’s credentials and the technological specifications of the filler rods before committing to a purchase. Buyers are advised to consult technical data sheets and user testimonials to ensure they are investing in a product that will perform reliably under the stress of repair or fabrication work. For welders who are just beginning to explore the use of cast iron filler rods, it’s beneficial to seek insights from experienced professionals or take part in workshops that offer practical, hands-on experience. This not only enhances trustworthiness in the skills being acquired but also fosters a deeper understanding of the subtle nuances involved in cast iron welding. Industry forums, trade-specific publications, and workshops can be valuable resources for learning the latest techniques and understanding the future trends impacting the use of these specialized fillers. In conclusion, the smart selection and application of cast iron filler rods are vital to maximizing structural integrity and achieving superior performance in weldments. Whether working on automotive restoration, industrial machinery repairs, or creating custom iron artworks, employing the correct filler rod and technique is paramount. As the industry continues to evolve, staying informed and continuously upgrading skills ensure that professionals remain at the forefront of innovation, providing effective solutions to challenging welding scenarios.

Related Video

Copyright © 2025 Dingzhou Jinlong Metal Production Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy