3/32 welding rod 6010 amps

Februari . 04, 2025 05:33

Choosing the correct settings for welding rods, particularly the 6010 variant, is pivotal for achieving optimal results in any welding operation. When aiming to use a 3/32 6010 welding rod, understanding the precise amp setting can influence the quality and integrity of the weld. This article will delve into this subject with an emphasis on real-world experiences, technical expertise, and authoritative insights.

Reference to industry standards and manufacturer guidelines adds credibility and authority to our understanding. For example, Lincoln Electric and other authoritative bodies in welding manufacturing suggest specific parameters based on extensive testing and application assessments. Following such guidelines can enhance weld quality and adhere to safety protocols. Trust in recommendations increases when they are backed by hands-on testing and endorsements by seasoned professionals. It's helpful to regularly consult experienced welding practitioners and instructors who not only train on these standards but also perform routine tasks using a variety of techniques and tools. For those new to welding, practicing on scrap material with various amp settings can greatly improve proficiency and understanding. Documenting each attempt and the resulting weld's appearance contributes to a personal log of data, which can be analyzed for improving technique and performance. Finally, while technology such as inverter-type machines offers more control over fine-tuning amperage settings, a welder's individual skill remains paramount. Consistent practice, knowledge of equipment, and a keen eye for detail are indispensable in achieving successful welds with 6010 rods. In summary, a 3/32 6010 welding rod requires thoughtful consideration of amperage settings, tailored to specific project demands, environmental conditions, and material characteristics. Experienced judgment informed by authoritative guidance ensures each weld meets safety and quality standards, fostering trust in the welding process's effectiveness.

Reference to industry standards and manufacturer guidelines adds credibility and authority to our understanding. For example, Lincoln Electric and other authoritative bodies in welding manufacturing suggest specific parameters based on extensive testing and application assessments. Following such guidelines can enhance weld quality and adhere to safety protocols. Trust in recommendations increases when they are backed by hands-on testing and endorsements by seasoned professionals. It's helpful to regularly consult experienced welding practitioners and instructors who not only train on these standards but also perform routine tasks using a variety of techniques and tools. For those new to welding, practicing on scrap material with various amp settings can greatly improve proficiency and understanding. Documenting each attempt and the resulting weld's appearance contributes to a personal log of data, which can be analyzed for improving technique and performance. Finally, while technology such as inverter-type machines offers more control over fine-tuning amperage settings, a welder's individual skill remains paramount. Consistent practice, knowledge of equipment, and a keen eye for detail are indispensable in achieving successful welds with 6010 rods. In summary, a 3/32 6010 welding rod requires thoughtful consideration of amperage settings, tailored to specific project demands, environmental conditions, and material characteristics. Experienced judgment informed by authoritative guidance ensures each weld meets safety and quality standards, fostering trust in the welding process's effectiveness.

Related Video

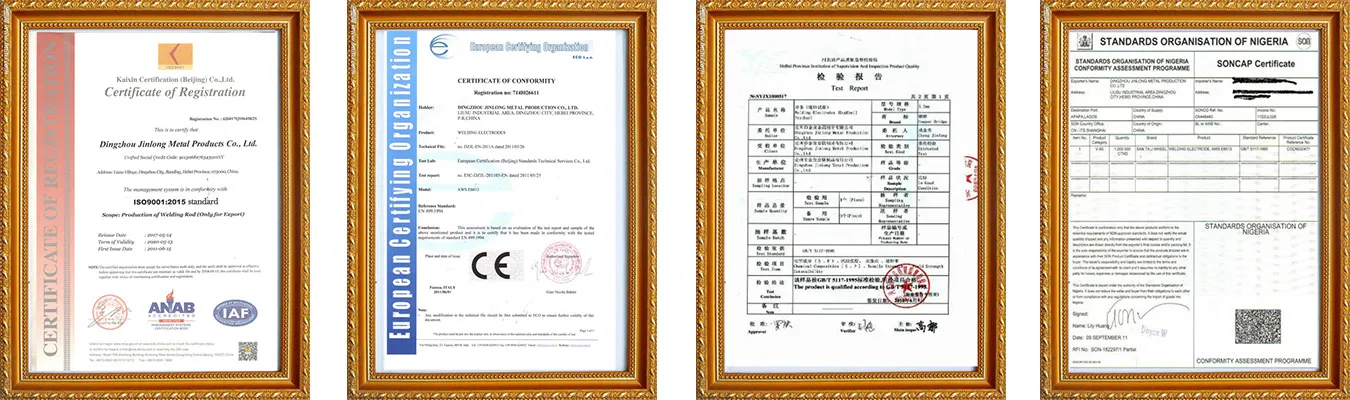

Copyright © 2025 Dingzhou Jinlong Metal Production Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy