e7018 3 32

Fev . 04, 2025 03:37

E7018 electrodes, often identified by their size, such as 3/32, are indispensable tools in the field of welding, renowned for their compatibility with various welding projects. For beginner and experienced welders alike, understanding the intricacies of this electrode type can significantly enhance the quality and efficiency of their work. This article delves into the practical experiences, professional insights, and the authoritative information surrounding E7018 3/32 electrodes.

Trustworthiness in the context of the E7018 3/32 electrode comes from the extensive field use and feedback from welding professionals. Commonly praised by users for its reliability, welders acknowledge the electrode’s consistency in delivering high-quality welds without the frequent occurrence of faults or weak joints. Experienced users suggest running this electrode with a slightly higher amperage setting to optimize its performance and achieve the precise results for which it's renowned. Furthermore, the longevity of the E7018 3/32 electrodes is noteworthy. Proper storage is crucial to maintaining their quality due to the low-hydrogen coating, which can absorb moisture if exposed to a damp environment. Welders are advised to store these electrodes in a regulated drying oven when not in use. For industrial applications where the quality of the weld cannot be compromised, reliance on E7018 3/32 electrodes remains high. Their ability to perform under stringent conditions while ensuring safety standards are met is documented across various industries. Whether in construction, manufacturing, or repair sectors, E7018 3/32 electrodes are trusted implicitly by professionals who prioritize productivity without sacrificing safety and quality. For those looking to invest in reliable, high-performance welding electrodes, the E7018 3/32 offers an unmatched combination of strength, efficiency, and ease of use. It's no surprise that this electrode continues to be a staple in the toolkit of professional welders around the globe, testament to its consummate balance between technical excellence and practical application.

Trustworthiness in the context of the E7018 3/32 electrode comes from the extensive field use and feedback from welding professionals. Commonly praised by users for its reliability, welders acknowledge the electrode’s consistency in delivering high-quality welds without the frequent occurrence of faults or weak joints. Experienced users suggest running this electrode with a slightly higher amperage setting to optimize its performance and achieve the precise results for which it's renowned. Furthermore, the longevity of the E7018 3/32 electrodes is noteworthy. Proper storage is crucial to maintaining their quality due to the low-hydrogen coating, which can absorb moisture if exposed to a damp environment. Welders are advised to store these electrodes in a regulated drying oven when not in use. For industrial applications where the quality of the weld cannot be compromised, reliance on E7018 3/32 electrodes remains high. Their ability to perform under stringent conditions while ensuring safety standards are met is documented across various industries. Whether in construction, manufacturing, or repair sectors, E7018 3/32 electrodes are trusted implicitly by professionals who prioritize productivity without sacrificing safety and quality. For those looking to invest in reliable, high-performance welding electrodes, the E7018 3/32 offers an unmatched combination of strength, efficiency, and ease of use. It's no surprise that this electrode continues to be a staple in the toolkit of professional welders around the globe, testament to its consummate balance between technical excellence and practical application.

Related Video

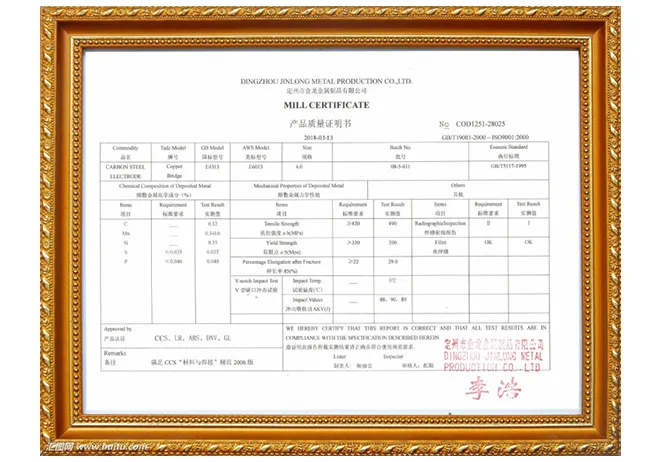

Copyright © 2025 Dingzhou Jinlong Metal Production Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy