welding rod types 7018

Jan . 10, 2025 10:03

Understanding the intricacies of welding rod types is essential for any professional welder, and the 7018 electrode stands out as a staple across various industries. Known for its versatility and strength, the 7018 welding rod is highly esteemed for its unique properties and wide-ranging applications.

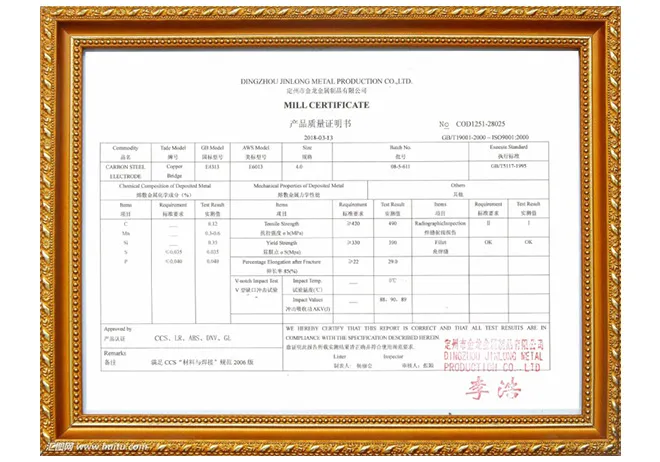

Furthermore, it is crucial to hone one’s skills with vertical and overhead welding when using the 7018 rod. Its thicker slag layer and fast-freeze properties can pose a challenge, making it imperative for welders to practice proper technique and positioning to achieve ideal penetration and bead appearance. Mastery of these techniques underscores the welder’s expertise and enhances the quality of the weld. Trustworthiness in welding performance also translates to the quality of the input materials. Opting for well-known brands that adhere to industry standards, such as AWS, guarantees the consistency and reliability of the electrodes. Professional-grade 7018 rods from reputed manufacturers undergo rigorous testing, providing assurance of their mechanical properties and performance capabilities. Ultimately, the 7018 welding rod’s authoritative standing in the welding domain underscores its efficacy in delivering robust and reliable joints. With its impeccable performance in combating cracking and its adaptability across myriad applications, the 7018 remains a preferred choice for many welding professionals. Through diligent practice and an informed approach, welders can unlock the full potential of the 7018, ensuring superior outcomes in their projects. Understanding its nuances and optimizing its application not only stands testament to a welder’s expertise but also fortifies their reputation for delivering exceptional welding results.

Furthermore, it is crucial to hone one’s skills with vertical and overhead welding when using the 7018 rod. Its thicker slag layer and fast-freeze properties can pose a challenge, making it imperative for welders to practice proper technique and positioning to achieve ideal penetration and bead appearance. Mastery of these techniques underscores the welder’s expertise and enhances the quality of the weld. Trustworthiness in welding performance also translates to the quality of the input materials. Opting for well-known brands that adhere to industry standards, such as AWS, guarantees the consistency and reliability of the electrodes. Professional-grade 7018 rods from reputed manufacturers undergo rigorous testing, providing assurance of their mechanical properties and performance capabilities. Ultimately, the 7018 welding rod’s authoritative standing in the welding domain underscores its efficacy in delivering robust and reliable joints. With its impeccable performance in combating cracking and its adaptability across myriad applications, the 7018 remains a preferred choice for many welding professionals. Through diligent practice and an informed approach, welders can unlock the full potential of the 7018, ensuring superior outcomes in their projects. Understanding its nuances and optimizing its application not only stands testament to a welder’s expertise but also fortifies their reputation for delivering exceptional welding results.

Related Video

Copyright © 2025 Dingzhou Jinlong Metal Production Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy