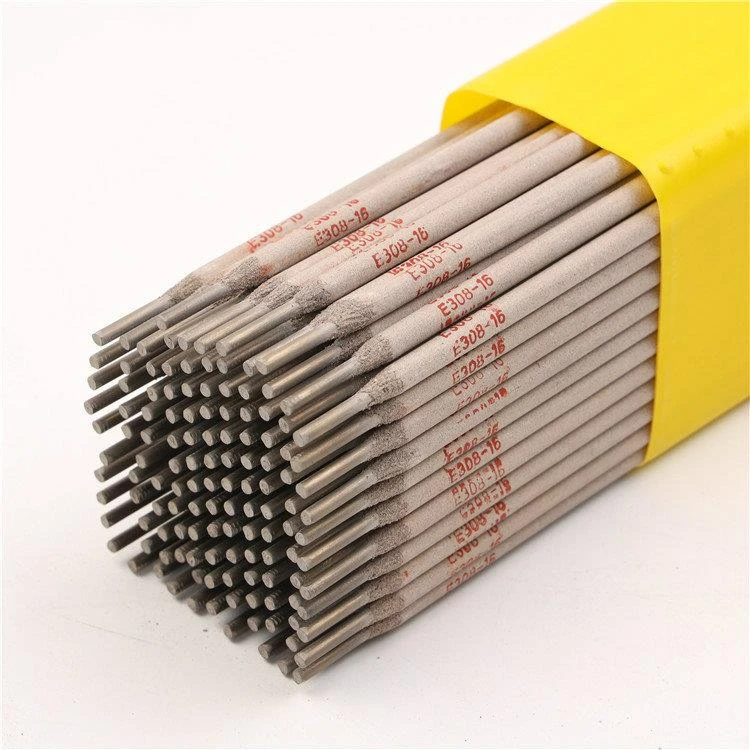

welding rod metal

Jan . 13, 2025 09:34

In the realm of metalworking, the welding rod stands as a cornerstone, bridging components with precision and strength. These essential tools, typically composed of various metal alloys, transform under the heat, forming bonds that are critical for structural integrity in a myriad of applications. Many professionals in construction, automotive, and manufacturing fields rely on welding rods not just for their utility, but for their role in ensuring safety and durability.

Expert welders emphasize the importance of adhering to best practices during the welding process. Techniques such as maintaining optimal temperatures and controlling the speed of the weld help prevent common issues like porosity or unwanted spatter. Furthermore, utilizing quality welding machines and protective gear significantly influences the weld quality and safety. Trust in your welding rods is not merely a matter of brand reputation but aligns closely with performance outcomes. Products from esteemed manufacturers undergo rigorous testing and quality control measures, ensuring consistent chemical composition and physical properties. This attention to detail fosters reliability, allowing artisans and engineers to execute projects with confidence. Sourcing and inventory management of welding rods also play a vital role in operational efficiency. Engaging with suppliers who offer a diverse range of rods, along with expert guidance, can streamline procurement processes, ensuring the right materials are always at hand. This proactive approach minimizes downtime and supports continuous project development. In conclusion, the welding rod is more than just a tool; it is a symbol of precision and reliability in the metalworking industry. Its significance cannot be overstated, providing an essential function in every welded creation. By understanding the intricacies of welding rod selection, application, and maintenance, professionals not only safeguard the quality of their work but also foster innovation in their industries. Embrace the value of knowledge in welding, where each rod holds the potential to transform raw metal into enduring frames and forms, shaping the future of craftsmanship and engineering.

Expert welders emphasize the importance of adhering to best practices during the welding process. Techniques such as maintaining optimal temperatures and controlling the speed of the weld help prevent common issues like porosity or unwanted spatter. Furthermore, utilizing quality welding machines and protective gear significantly influences the weld quality and safety. Trust in your welding rods is not merely a matter of brand reputation but aligns closely with performance outcomes. Products from esteemed manufacturers undergo rigorous testing and quality control measures, ensuring consistent chemical composition and physical properties. This attention to detail fosters reliability, allowing artisans and engineers to execute projects with confidence. Sourcing and inventory management of welding rods also play a vital role in operational efficiency. Engaging with suppliers who offer a diverse range of rods, along with expert guidance, can streamline procurement processes, ensuring the right materials are always at hand. This proactive approach minimizes downtime and supports continuous project development. In conclusion, the welding rod is more than just a tool; it is a symbol of precision and reliability in the metalworking industry. Its significance cannot be overstated, providing an essential function in every welded creation. By understanding the intricacies of welding rod selection, application, and maintenance, professionals not only safeguard the quality of their work but also foster innovation in their industries. Embrace the value of knowledge in welding, where each rod holds the potential to transform raw metal into enduring frames and forms, shaping the future of craftsmanship and engineering.

Related Video

Copyright © 2025 Dingzhou Jinlong Metal Production Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy