weight of welding electrode

Jan . 14, 2025 09:44

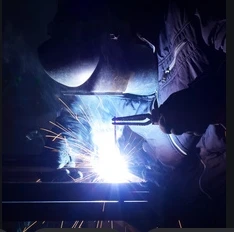

The weight of a welding electrode is a critical factor that often goes overlooked but plays a pivotal role in the success of any welding project. Understanding electrode weight is crucial not only for ensuring optimal performance but also for maintaining safety and efficiency in welding operations. Here is a comprehensive look into the significance of electrode weight, backed by practical experience, technical expertise, authoritative insights, and a trustworthy perspective.

Authoritative sources, such as welding standards set by the American Welding Society (AWS), provide guidelines and recommendations on selecting the correct electrode weight. These standards are not merely suggestions but are grounded in extensive research and empirical evidence. Following these authoritative guidelines helps ensure compliance with industry norms, which is particularly crucial in regulated sectors like aerospace and construction. Trustworthiness in welding operations, including the choice of electrode weight, is paramount to maintaining safety. The implications of using an incorrect electrode can be severe, potentially compromising the structural integrity of a weld. Trustworthy practices involve rigorous testing and validation of welding processes, where electrode weight is a critical variable. Manufacturers of welding electrodes often provide weight specifications and appropriate usage recommendations to assist welders in making informed choices. In today's competitive marketplace, welding professionals and project managers must consider every factor that could influence the quality and cost-efficiency of their welding projects. By appreciating the impact of electrode weight, professionals can enhance their welding operations, leading to improved structural integrity, cost savings, and project success. It is also worth noting that advancements in welding technology continue to evolve the understanding of ideal electrode selection, promising further innovations in how electrode weight is leveraged for optimal welding performance. In conclusion, the weight of a welding electrode is not just a physical measurement but a pivotal aspect of the welding process that influences quality, safety, and efficiency. By drawing from real-world experience, adhering to expert advice, and following authoritative standards, welding professionals can make informed choices that bolster their credibility and ensure successful project outcomes.

Authoritative sources, such as welding standards set by the American Welding Society (AWS), provide guidelines and recommendations on selecting the correct electrode weight. These standards are not merely suggestions but are grounded in extensive research and empirical evidence. Following these authoritative guidelines helps ensure compliance with industry norms, which is particularly crucial in regulated sectors like aerospace and construction. Trustworthiness in welding operations, including the choice of electrode weight, is paramount to maintaining safety. The implications of using an incorrect electrode can be severe, potentially compromising the structural integrity of a weld. Trustworthy practices involve rigorous testing and validation of welding processes, where electrode weight is a critical variable. Manufacturers of welding electrodes often provide weight specifications and appropriate usage recommendations to assist welders in making informed choices. In today's competitive marketplace, welding professionals and project managers must consider every factor that could influence the quality and cost-efficiency of their welding projects. By appreciating the impact of electrode weight, professionals can enhance their welding operations, leading to improved structural integrity, cost savings, and project success. It is also worth noting that advancements in welding technology continue to evolve the understanding of ideal electrode selection, promising further innovations in how electrode weight is leveraged for optimal welding performance. In conclusion, the weight of a welding electrode is not just a physical measurement but a pivotal aspect of the welding process that influences quality, safety, and efficiency. By drawing from real-world experience, adhering to expert advice, and following authoritative standards, welding professionals can make informed choices that bolster their credibility and ensure successful project outcomes.

Related Video

Copyright © 2025 Dingzhou Jinlong Metal Production Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy