use of welding rod

Jan . 14, 2025 09:42

The utilization of welding rods is fundamental in the realm of metal fabrication and repair. These versatile tools are indispensable for achieving strong, reliable welds, ensuring that structures, from small-scale repairs to grand engineering feats, maintain their integrity and longevity. A deeper understanding of welding rod functionalities, types, and applications can significantly improve desirability and performance in diverse welding projects.

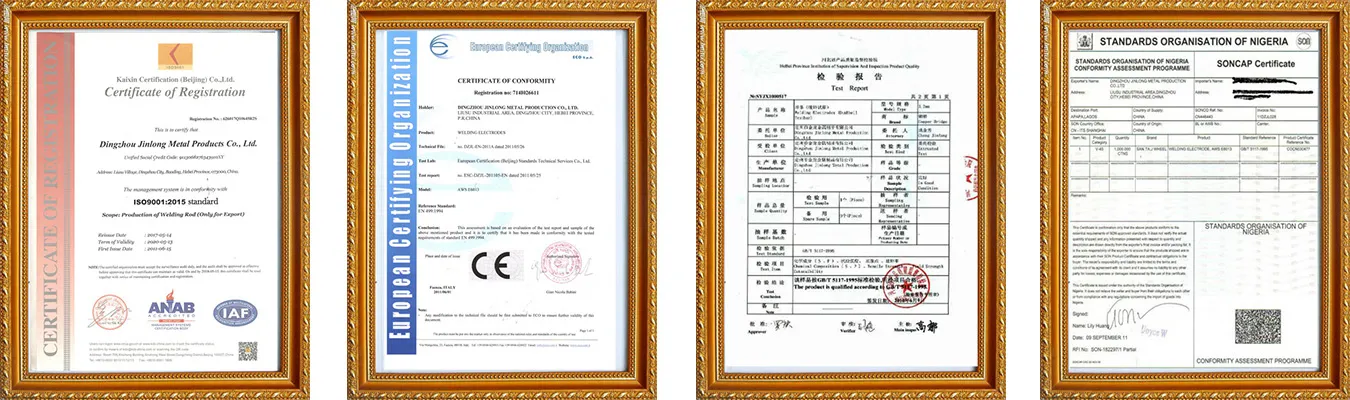

Moreover, the welding environment influences the choice of rods considerably. Outdoor projects often require rods that endure wind and variable weather conditions, whereas indoor or controlled environments allow for more flexibility. The E7018 rod, known for its low-hydrogen properties, is an excellent choice for projects demanding high resistance to cracking and superior strength under stress. The proficiency in wielding welding rods not only bolsters the structural integrity of welds but also reduces the likelihood of defects. Familiarity with the voltage settings, amperage, and appropriate welding speed all contribute to the creation of a strong, uniform weld bead. Additionally, maintaining the chosen rod at the correct angle and pace prevents issues like undercutting or slag inclusions, which could compromise the durability of the weld. For optimal trustworthiness and authoritativeness in product selection and usage, relying on reputable brands and manufacturers is advisable. Renowned names in the welding industry invest in rigorous testing and quality control, offering products that meet international standards. Furthermore, consulting with seasoned welding engineers or technical experts can provide crucial insights and recommendations tailored to specific project requirements. In sum, welding rods epitomize a core component in the toolkit of any professional welder. Understanding their applications, attributes, and effective usage is essential for anyone endeavoring in the skilled craftsmanship of metalwork. By leveraging expert knowledge and trusted products, welders can ensure they produce high-quality results that stand the test of time, effectively endorsing the significance of welding rods in the field of metal fabrication.

Moreover, the welding environment influences the choice of rods considerably. Outdoor projects often require rods that endure wind and variable weather conditions, whereas indoor or controlled environments allow for more flexibility. The E7018 rod, known for its low-hydrogen properties, is an excellent choice for projects demanding high resistance to cracking and superior strength under stress. The proficiency in wielding welding rods not only bolsters the structural integrity of welds but also reduces the likelihood of defects. Familiarity with the voltage settings, amperage, and appropriate welding speed all contribute to the creation of a strong, uniform weld bead. Additionally, maintaining the chosen rod at the correct angle and pace prevents issues like undercutting or slag inclusions, which could compromise the durability of the weld. For optimal trustworthiness and authoritativeness in product selection and usage, relying on reputable brands and manufacturers is advisable. Renowned names in the welding industry invest in rigorous testing and quality control, offering products that meet international standards. Furthermore, consulting with seasoned welding engineers or technical experts can provide crucial insights and recommendations tailored to specific project requirements. In sum, welding rods epitomize a core component in the toolkit of any professional welder. Understanding their applications, attributes, and effective usage is essential for anyone endeavoring in the skilled craftsmanship of metalwork. By leveraging expert knowledge and trusted products, welders can ensure they produce high-quality results that stand the test of time, effectively endorsing the significance of welding rods in the field of metal fabrication.

Related Video

Copyright © 2025 Dingzhou Jinlong Metal Production Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy