cast iron filler rod

Feb . 15, 2025 03:05

When facing the challenge of welding stainless steel to mild steel, selecting the right filler rod is crucial for a successful and durable joint. This topic often perplexes both novice and seasoned welders due to the contrasting properties of these metals. However, understanding the nuances of material compatibility, proper rod selection, and technique can significantly impact the outcome.

Safety is another aspect where expertise can't be overstated. Proper personal protective equipment (PPE) is non-negotiable when working with these materials, especially since the alloying elements in stainless steel, such as chromium, can produce hazardous fumes. A well-ventilated area or proper exhaust system is essential to protect the welder from potential health risks. In terms of quality control, post-weld inspection is critical, particularly for projects requiring high strength and durability. Visual inspections should look for surface defects such as cracks, while more advanced techniques like radiographic or ultrasonic testing can detect subsurface flaws. These inspections are vital to ensure the integrity of the weld and the overall structure it supports. Trustworthiness in completed welds between stainless and mild steel is seen not just in immediate results but in long-term performance. With the right filler rod, preparation, and technique, these joints can withstand the rigors of time and application-specific conditions. Successfully mastering this welding process can lead to greater projects, ensuring that the blend of stainless steel's resilience and mild steel's versatility is effectively utilized. Ultimately, welding stainless steel to mild steel with the correct filler rod such as ER309L is not just about technical execution but also about understanding the underlying materials science. It demands a balance of experience, expertise, and attention to detail to produce welds that are not only strong but dependable in their intended application.

Safety is another aspect where expertise can't be overstated. Proper personal protective equipment (PPE) is non-negotiable when working with these materials, especially since the alloying elements in stainless steel, such as chromium, can produce hazardous fumes. A well-ventilated area or proper exhaust system is essential to protect the welder from potential health risks. In terms of quality control, post-weld inspection is critical, particularly for projects requiring high strength and durability. Visual inspections should look for surface defects such as cracks, while more advanced techniques like radiographic or ultrasonic testing can detect subsurface flaws. These inspections are vital to ensure the integrity of the weld and the overall structure it supports. Trustworthiness in completed welds between stainless and mild steel is seen not just in immediate results but in long-term performance. With the right filler rod, preparation, and technique, these joints can withstand the rigors of time and application-specific conditions. Successfully mastering this welding process can lead to greater projects, ensuring that the blend of stainless steel's resilience and mild steel's versatility is effectively utilized. Ultimately, welding stainless steel to mild steel with the correct filler rod such as ER309L is not just about technical execution but also about understanding the underlying materials science. It demands a balance of experience, expertise, and attention to detail to produce welds that are not only strong but dependable in their intended application.

Related Video

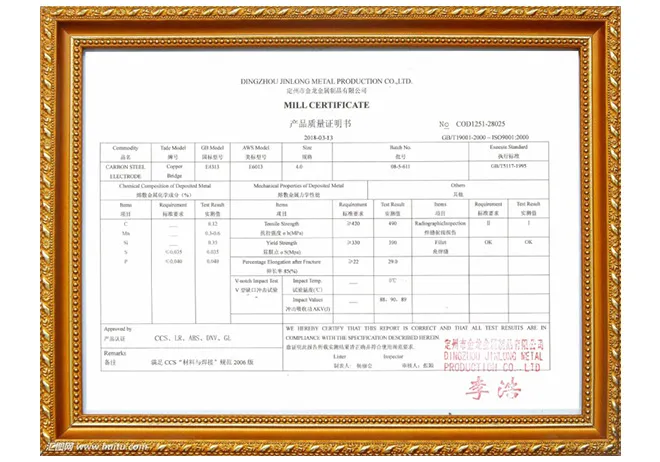

Copyright © 2025 Dingzhou Jinlong Metal Production Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy