cast iron tig filler rod

Feb . 15, 2025 03:29

Choosing the right filler rod is crucial for successful TIG welding, particularly when working with stainless steel. Filler rods play a significant role in achieving weld strength, corrosion resistance, and a smooth finish. Understanding which filler rod to use can set professionals apart in producing high-quality, durable welds. This guide explores key considerations and expert recommendations to help you make informed decisions about using filler rods for TIG welding stainless steel.

From a professional standpoint, factors such as weld cleanliness and methodical preparation hugely influence the performance of the filler rod in stainless steel welds. Proper cleaning of both the rod and the base metal before welding prevents contamination and ensures superior adhesion. It's not uncommon for impurities to migrate into the weld pool if surfaces are neglected, leading to defects like porosity or weak joints which can significantly impact the longevity and safety of the welded structure. Manufacturers and suppliers play a pivotal role in providing detailed specifications and technical support for filler rod selections. Additionally, authoritative resources such as welding manuals, metallurgy texts, and industry standards offer invaluable information that enhances the decision-making process. For ongoing learning and adaptation to evolving materials technology, engaging with welding forums and related professional communities can provide real-world insights beyond theoretical knowledge. Consistency is key in maintaining quality across prior and future welds. Documenting previous successes and challenges with different filler rods can aid in forecasting requirements for similar projects. Moreover, adapting to technological advances in welding equipment and processes can result in greater efficiency and enhanced quality outcomes in modern applications. Lastly, the trust integrated into one's craftsmanship is shown through a commitment to quality materials and practices. For compliable and enduring results in TIG welding of stainless steel, the conscientious selection of filler rods is an indispensable aspect underscoring a welder's expertise across diverse and demanding projects.

From a professional standpoint, factors such as weld cleanliness and methodical preparation hugely influence the performance of the filler rod in stainless steel welds. Proper cleaning of both the rod and the base metal before welding prevents contamination and ensures superior adhesion. It's not uncommon for impurities to migrate into the weld pool if surfaces are neglected, leading to defects like porosity or weak joints which can significantly impact the longevity and safety of the welded structure. Manufacturers and suppliers play a pivotal role in providing detailed specifications and technical support for filler rod selections. Additionally, authoritative resources such as welding manuals, metallurgy texts, and industry standards offer invaluable information that enhances the decision-making process. For ongoing learning and adaptation to evolving materials technology, engaging with welding forums and related professional communities can provide real-world insights beyond theoretical knowledge. Consistency is key in maintaining quality across prior and future welds. Documenting previous successes and challenges with different filler rods can aid in forecasting requirements for similar projects. Moreover, adapting to technological advances in welding equipment and processes can result in greater efficiency and enhanced quality outcomes in modern applications. Lastly, the trust integrated into one's craftsmanship is shown through a commitment to quality materials and practices. For compliable and enduring results in TIG welding of stainless steel, the conscientious selection of filler rods is an indispensable aspect underscoring a welder's expertise across diverse and demanding projects.

Related Video

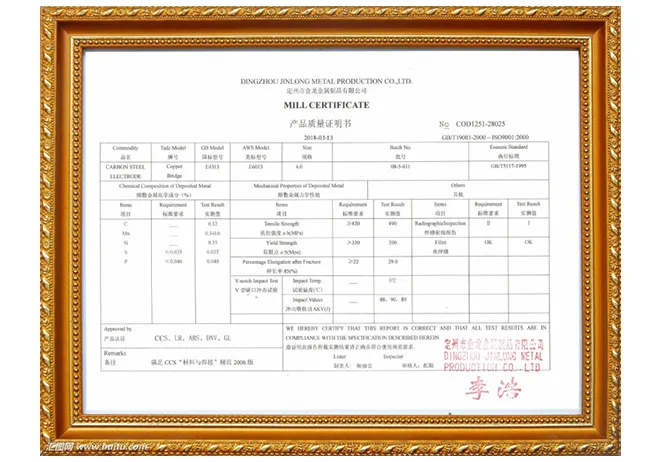

Copyright © 2025 Dingzhou Jinlong Metal Production Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy