e312 welding rod

Feb . 13, 2025 23:37

The E312 welding rod is a cornerstone in the world of welding for both novice and experienced welders. Its versatility and performance make it a crucial tool across various industrial applications. To those unfamiliar, the E312 welding rod is renowned for its superior combination of strength, corrosion resistance, and weldability, making it an excellent choice for joining dissimilar metals or welding stainless steel with carbon steel.

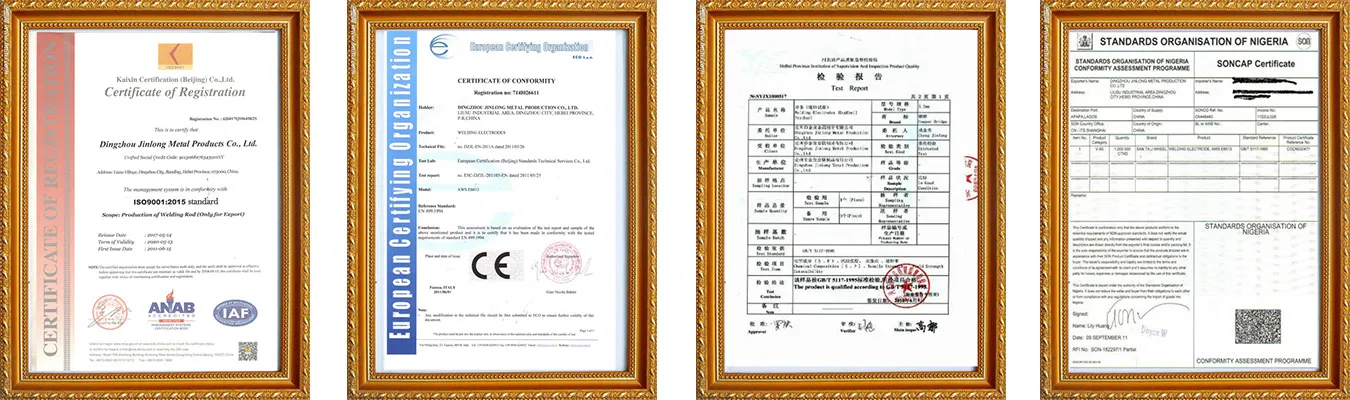

Trustworthiness is crucial and the E312 provides a peace of mind that can only be derived from a history of reliable performance. Manufacturers producing E312 rods often adhere to rigorous quality control procedures, ensuring that each rod meets the stringent specifications necessary for industrial use. This adherence to quality not only enhances weld integrity but also bolsters the consumable’s reputation among professional welders. Welders can proceed with confidence, knowing that their choice of E312 helps mitigate the risk of joint failure or premature wear. Moreover, the E312 welding rod supports versatility in technique. It can be employed across multiple welding processes, including shielded metal arc welding (SMAW) and manual metal arc (MMA) welding. This flexibility is particularly beneficial for those who require adaptability in their workflow, such as repair technicians who encounter a variety of metal types and configurations daily. Additionally, being relatively easy to ignite and manage, it is often recommended for workshops aiming to maximize both productivity and the quality of output. In the fast-paced world of industrial fabrication and maintenance, where efficiency and reliability are critical, the E312 welding rod stands as an essential tool. Its unique chemical and physical properties equip it for an extensive range of applications, from marine to construction, showcasing an unparalleled ability to unite disparate metal types while providing longevity and fatigue resistance. This positions the E312 not merely as a tool but as a pivotal enabler of industrial continuity and technological advancement. Ultimately, leveraging the E312 welding rod translates to improved performance metrics and compliance with industry standards, ensuring infrastructure and components that not only meet but often exceed expectations. For those invested in producing high-quality, reliable structures or machinery, incorporating E312 into their welding practices represents a commitment to excellence.

Trustworthiness is crucial and the E312 provides a peace of mind that can only be derived from a history of reliable performance. Manufacturers producing E312 rods often adhere to rigorous quality control procedures, ensuring that each rod meets the stringent specifications necessary for industrial use. This adherence to quality not only enhances weld integrity but also bolsters the consumable’s reputation among professional welders. Welders can proceed with confidence, knowing that their choice of E312 helps mitigate the risk of joint failure or premature wear. Moreover, the E312 welding rod supports versatility in technique. It can be employed across multiple welding processes, including shielded metal arc welding (SMAW) and manual metal arc (MMA) welding. This flexibility is particularly beneficial for those who require adaptability in their workflow, such as repair technicians who encounter a variety of metal types and configurations daily. Additionally, being relatively easy to ignite and manage, it is often recommended for workshops aiming to maximize both productivity and the quality of output. In the fast-paced world of industrial fabrication and maintenance, where efficiency and reliability are critical, the E312 welding rod stands as an essential tool. Its unique chemical and physical properties equip it for an extensive range of applications, from marine to construction, showcasing an unparalleled ability to unite disparate metal types while providing longevity and fatigue resistance. This positions the E312 not merely as a tool but as a pivotal enabler of industrial continuity and technological advancement. Ultimately, leveraging the E312 welding rod translates to improved performance metrics and compliance with industry standards, ensuring infrastructure and components that not only meet but often exceed expectations. For those invested in producing high-quality, reliable structures or machinery, incorporating E312 into their welding practices represents a commitment to excellence.

Related Video

Copyright © 2025 Dingzhou Jinlong Metal Production Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy