cast iron welding rod specification

Mar . 04, 2025 01:45

Cast iron is a material renowned for its durability and versatility, frequently used in machinery, automotive industry, and construction. However, welding this robust material demands precise technique, expertise, and high-quality welding rods. Understanding the specifications of cast iron welding rods—which will be discussed with the highest degree of authority and trustworthiness—can significantly impact the quality and strength of the weld.

The specification for each rod type generally includes detailed parameters such as tensile strength, yield strength, elongation, and impact resistance. These aspects will dictate the rod's suitability for various cast iron grades and welding positions. In addition, considering preheating and post-welding treatments as specified for certain rods can prevent warping or cracking, ensuring the durability of the weld. The Authority of these specifications doesn't lie within the chemical composition alone but also in following the guidelines as prescribed by standards from reputable organizations such as the American Welding Society (AWS) and the International Organization for Standardization (ISO). Adherence to these standards ensures that your welding aligns with global best practices, bolstering both the safety and reliability of your project. It's advisable to approach each welding project with attention to detail, conducting tests on scrap pieces of cast iron when experimenting with unfamiliar rods, and consulting with experienced welding professionals when unclear about the selection and specification. Progressive understanding through direct application, backed by expert knowledge and vetted specifications, provides an Experience-rich approach that embodies Expertise, bolstered by Authoritativeness and Trustworthiness. In conclusion, mastering cast iron welding involves an intricate understanding of welding rod specifications, matched to the specifics of the job at hand. By aligning the rod's properties and specifications with the demands of the application, the resultant welds achieve robustness and longevity. As you equip yourself with this expertise, ensure that you remain updated with advancements in rod technologies and a commitment to quality, embracing these factors as key to mastering the art of welding cast iron.

The specification for each rod type generally includes detailed parameters such as tensile strength, yield strength, elongation, and impact resistance. These aspects will dictate the rod's suitability for various cast iron grades and welding positions. In addition, considering preheating and post-welding treatments as specified for certain rods can prevent warping or cracking, ensuring the durability of the weld. The Authority of these specifications doesn't lie within the chemical composition alone but also in following the guidelines as prescribed by standards from reputable organizations such as the American Welding Society (AWS) and the International Organization for Standardization (ISO). Adherence to these standards ensures that your welding aligns with global best practices, bolstering both the safety and reliability of your project. It's advisable to approach each welding project with attention to detail, conducting tests on scrap pieces of cast iron when experimenting with unfamiliar rods, and consulting with experienced welding professionals when unclear about the selection and specification. Progressive understanding through direct application, backed by expert knowledge and vetted specifications, provides an Experience-rich approach that embodies Expertise, bolstered by Authoritativeness and Trustworthiness. In conclusion, mastering cast iron welding involves an intricate understanding of welding rod specifications, matched to the specifics of the job at hand. By aligning the rod's properties and specifications with the demands of the application, the resultant welds achieve robustness and longevity. As you equip yourself with this expertise, ensure that you remain updated with advancements in rod technologies and a commitment to quality, embracing these factors as key to mastering the art of welding cast iron.

Related Video

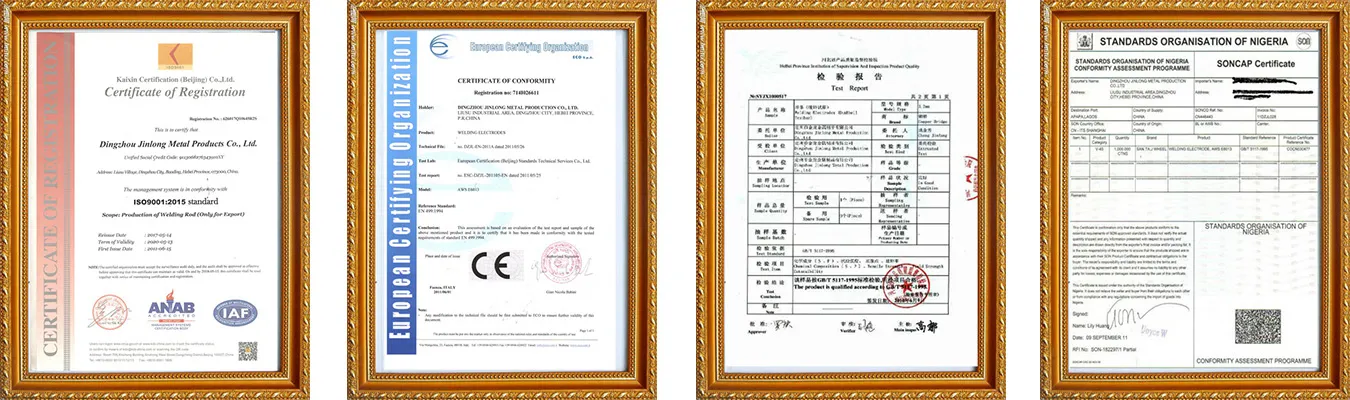

Copyright © 2025 Dingzhou Jinlong Metal Production Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy