casting welding rod number

Mar . 04, 2025 02:06

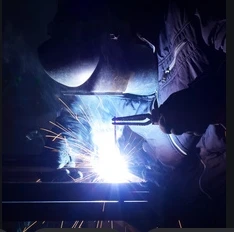

Casting welding rod numbers are a crucial component in the world of metal fabrication and repair, a field characterized by its intricate craft and reliance on high-quality materials. These numbers are not mere identifiers; they are a gateway to understanding the specifications, capabilities, and appropriate applications of welding rods. For industry professionals, selecting the right casting welding rod can make a significant difference in the quality and durability of a weld.

Precision in application is critical, particularly where casting welding rods are concerned. Imagine a pipeline that transports high-pressure oils; the welds must endure extreme conditions without failing. This is where expertise becomes paramount. Using a rod that promises high tensile strength is not enough—understanding the precise requirements of the specific alloy being joined ensures the integrity of the joint. An authoritative grasp of metallurgy allows professionals to recommend welding rods that meet exact industry specifications, minimize weld defects, and extend the lifespan of the metal infrastructure. Given the complexity of the job, trustworthiness in advice regarding casting welding rod selection cannot be overstated. Professionals must rely on verified and dependable information. For credibility, consulting technical data sheets provided by manufacturers is essential. These documents offer a blueprint of the welding rod’s characteristics, ensuring that welders align their choice with the project demands. Over time, welders accumulate a repertoire of trusted rod brands that consistently deliver on their metallurgical promises. In practice, the choice of a casting welding rod also ties into the economics of a project. Selecting a higher-number rod might suggest superior tensile strength, and yet, it could lead to increased costs without proportional performance benefits for specific projects. This emphasizes why experienced welders must also possess a nuanced understanding of project requirements versus rod specifications to ensure cost-effective outcomes. In conclusion, casting welding rod numbers are far more than arbitrary codes. They hold the key to executing precise and reliable welds in demanding industrial applications. Through honing expertise, leveraging authoritative sources of information, and building trust with clients and within teams, welders optimize their craft—and achieve not just industry standards, but set new benchmarks in metalworking excellence. With this internal compass directed towards Experience, Expertise, Authoritativeness, and Trustworthiness, professionals in the field not only meet the needs of today's projects but also shape the future of metal industry innovation.

Precision in application is critical, particularly where casting welding rods are concerned. Imagine a pipeline that transports high-pressure oils; the welds must endure extreme conditions without failing. This is where expertise becomes paramount. Using a rod that promises high tensile strength is not enough—understanding the precise requirements of the specific alloy being joined ensures the integrity of the joint. An authoritative grasp of metallurgy allows professionals to recommend welding rods that meet exact industry specifications, minimize weld defects, and extend the lifespan of the metal infrastructure. Given the complexity of the job, trustworthiness in advice regarding casting welding rod selection cannot be overstated. Professionals must rely on verified and dependable information. For credibility, consulting technical data sheets provided by manufacturers is essential. These documents offer a blueprint of the welding rod’s characteristics, ensuring that welders align their choice with the project demands. Over time, welders accumulate a repertoire of trusted rod brands that consistently deliver on their metallurgical promises. In practice, the choice of a casting welding rod also ties into the economics of a project. Selecting a higher-number rod might suggest superior tensile strength, and yet, it could lead to increased costs without proportional performance benefits for specific projects. This emphasizes why experienced welders must also possess a nuanced understanding of project requirements versus rod specifications to ensure cost-effective outcomes. In conclusion, casting welding rod numbers are far more than arbitrary codes. They hold the key to executing precise and reliable welds in demanding industrial applications. Through honing expertise, leveraging authoritative sources of information, and building trust with clients and within teams, welders optimize their craft—and achieve not just industry standards, but set new benchmarks in metalworking excellence. With this internal compass directed towards Experience, Expertise, Authoritativeness, and Trustworthiness, professionals in the field not only meet the needs of today's projects but also shape the future of metal industry innovation.

Related Video

Copyright © 2025 Dingzhou Jinlong Metal Production Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy