carbon steel electrode

Jan . 14, 2025 12:22

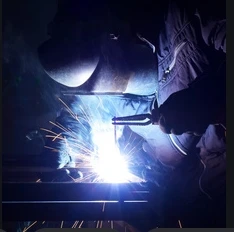

Carbon steel electrodes are indispensable tools in the welding industry, offering robustness and versatility for various applications. Having spent years in the field, my experience has shown that choosing the right electrode is crucial for achieving desired results in both construction and manufacturing processes.

From an economic perspective, carbon steel electrodes offer excellent cost-efficiency. The reusability and longevity of these electrodes result in lower overall costs for long-term projects. For instance, in shipbuilding, where precision and adherence to design specifications are non-negotiable, carbon steel electrodes have proven indispensable. Their adaptability in welding various steel grades without compromising the mechanical properties of the joint ensures a high return on investment. Another critical insight from my fieldwork is the importance of proper storage and handling of carbon steel electrodes to preserve their efficacy. Moisture exposure can lead to hydrogen contamination, adversely affecting weld quality. Therefore, maintaining a dry storage environment, alongside using a dedicated oven for baking electrodes before use, forms an essential best practice for ensuring optimal performance. In summary, the practical insights and field experiences reaffirm the value of carbon steel electrodes as a fundamental asset in welding applications. With their proven track record, backed by industry certifications and unwavering commitment to quality from leading manufacturers, these electrodes undoubtedly hold a position of authority and trust within the industry, facilitating projects with both reliability and excellence.

From an economic perspective, carbon steel electrodes offer excellent cost-efficiency. The reusability and longevity of these electrodes result in lower overall costs for long-term projects. For instance, in shipbuilding, where precision and adherence to design specifications are non-negotiable, carbon steel electrodes have proven indispensable. Their adaptability in welding various steel grades without compromising the mechanical properties of the joint ensures a high return on investment. Another critical insight from my fieldwork is the importance of proper storage and handling of carbon steel electrodes to preserve their efficacy. Moisture exposure can lead to hydrogen contamination, adversely affecting weld quality. Therefore, maintaining a dry storage environment, alongside using a dedicated oven for baking electrodes before use, forms an essential best practice for ensuring optimal performance. In summary, the practical insights and field experiences reaffirm the value of carbon steel electrodes as a fundamental asset in welding applications. With their proven track record, backed by industry certifications and unwavering commitment to quality from leading manufacturers, these electrodes undoubtedly hold a position of authority and trust within the industry, facilitating projects with both reliability and excellence.

Related Video

Copyright © 2025 Dingzhou Jinlong Metal Production Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy