welding electrodes explained

Jan . 14, 2025 12:17

Welding electrodes play an essential role in the welding process, serving as the filler metal that bonds two pieces together. A deep understanding of electrodes can dramatically enhance the quality of your weld, regardless of whether you're a seasoned professional or a passionate hobbyist. This article discusses welding electrodes from a product-focused viewpoint, expounding on their essential features, applications, and how to select the right one for your project.

Furthermore, understanding the position in which you'll be welding can guide your electrode choice. Some electrodes are versatile and can be used in all positions (flat, horizontal, vertical, and overhead), while others specialize in either vertical or flat positions. For instance, E6010 is valued for its deep penetration and versatile position use, making it suitable for root passes in pipe welding. In addition to the material and position, the power source being used also impacts electrode selection. Certain electrodes are designed for alternating current (AC), while others work best with direct current (DC). Knowing your equipment's capabilities ensures you select an electrode that will function optimally with your setup. Storage and care of welding electrodes is another point of consideration. Proper storage conditions, such as a dry, climate-controlled environment, extend the life of your electrodes and prevent moisture-induced issues like hydrogen cracking. It's advisable to individually inspect electrodes before use, ensuring they are free of rust or any coating damage. Safety should never be overlooked. Appropriate gear, including gloves, protective eyewear, and ventilation systems, is essential during welding to avoid injuries from high temperatures, sparks, and harmful fumes. In summary, the adept selection and use of welding electrodes can significantly influence the quality and durability of your welds. By understanding the different types of electrodes, their appropriate applications, and how to handle them correctly, you position yourself not just as a user, but as a master of your welding craft. From the right electrode, a world of superior welding awaits.

Furthermore, understanding the position in which you'll be welding can guide your electrode choice. Some electrodes are versatile and can be used in all positions (flat, horizontal, vertical, and overhead), while others specialize in either vertical or flat positions. For instance, E6010 is valued for its deep penetration and versatile position use, making it suitable for root passes in pipe welding. In addition to the material and position, the power source being used also impacts electrode selection. Certain electrodes are designed for alternating current (AC), while others work best with direct current (DC). Knowing your equipment's capabilities ensures you select an electrode that will function optimally with your setup. Storage and care of welding electrodes is another point of consideration. Proper storage conditions, such as a dry, climate-controlled environment, extend the life of your electrodes and prevent moisture-induced issues like hydrogen cracking. It's advisable to individually inspect electrodes before use, ensuring they are free of rust or any coating damage. Safety should never be overlooked. Appropriate gear, including gloves, protective eyewear, and ventilation systems, is essential during welding to avoid injuries from high temperatures, sparks, and harmful fumes. In summary, the adept selection and use of welding electrodes can significantly influence the quality and durability of your welds. By understanding the different types of electrodes, their appropriate applications, and how to handle them correctly, you position yourself not just as a user, but as a master of your welding craft. From the right electrode, a world of superior welding awaits.

Related Video

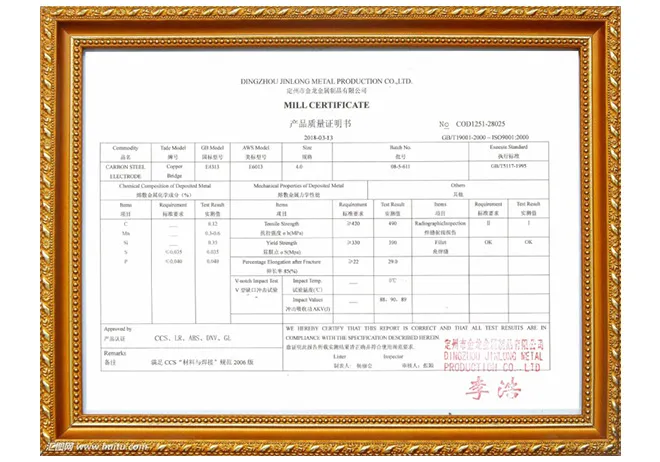

Copyright © 2025 Dingzhou Jinlong Metal Production Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy