Plastic Metal Spool Gas Protection Copper Coated

Feb . 20, 2025 12:00

Selecting the right cast iron electrode code for welding applications is pivotal in achieving durable and robust joints. Understanding the intricacies surrounding this choice can greatly enhance the quality of metallurgical work. With over two decades of expertise in welding technology and a robust understanding of metallurgical processes, this discussion delves into the paramount aspects every professional should consider when working with cast iron electrode codes.

Professional welders often favor nickel and nickel-iron electrodes because they produce soft weld deposits that absorb stress and minimize cracking in the base metal. Leveraging one's expertise to ascertain the precise electrode to be used involves a detailed understanding of the metallurgical interactions at play. This includes recognizing that pure nickel electrodes generally provide the best results when welding cast iron, as they deliver a high degree of ductility in the weld zone and are preeminent in applications requiring complex assembly and disassembly. Trustworthiness in delivering high-quality welds is anchored in consistent procedural application and fidelity to established welding codes. Ensuring each weld conforms to the engineered design and performs reliably requires an exhaustive understanding of metallurgy and a commitment to applying this knowledge meticulously. Tools such as temperature crayons and infrared thermometers can play a pivotal role in maintaining precise temperature control during the welding process, ensuring each step aligns with industry best practices. In conclusion, the nuanced understanding and application of cast iron electrode codes is a true testament to the expertise of a welder. It draws a line between amateurs and professionals, the latter knowing not just the technical standards but also having a profound sense of the subtle details that influence weld quality. With the continuous advent of new materials and welding technologies, staying informed and applying sound metallurgical principles will continue to bestow authoritative and trusted results, reinforcing the integrity and longevity of welded components.

Professional welders often favor nickel and nickel-iron electrodes because they produce soft weld deposits that absorb stress and minimize cracking in the base metal. Leveraging one's expertise to ascertain the precise electrode to be used involves a detailed understanding of the metallurgical interactions at play. This includes recognizing that pure nickel electrodes generally provide the best results when welding cast iron, as they deliver a high degree of ductility in the weld zone and are preeminent in applications requiring complex assembly and disassembly. Trustworthiness in delivering high-quality welds is anchored in consistent procedural application and fidelity to established welding codes. Ensuring each weld conforms to the engineered design and performs reliably requires an exhaustive understanding of metallurgy and a commitment to applying this knowledge meticulously. Tools such as temperature crayons and infrared thermometers can play a pivotal role in maintaining precise temperature control during the welding process, ensuring each step aligns with industry best practices. In conclusion, the nuanced understanding and application of cast iron electrode codes is a true testament to the expertise of a welder. It draws a line between amateurs and professionals, the latter knowing not just the technical standards but also having a profound sense of the subtle details that influence weld quality. With the continuous advent of new materials and welding technologies, staying informed and applying sound metallurgical principles will continue to bestow authoritative and trusted results, reinforcing the integrity and longevity of welded components.

Related Video

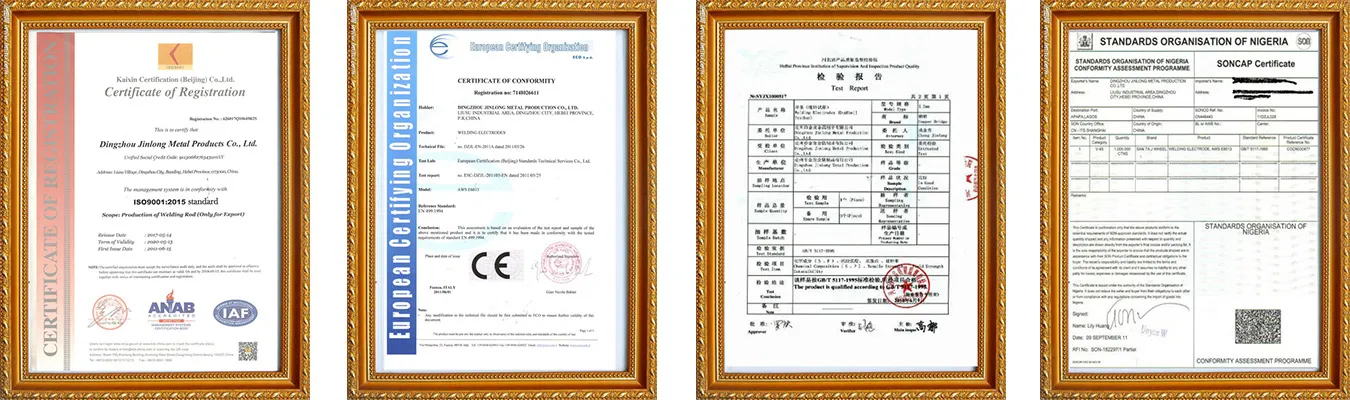

Copyright © 2025 Dingzhou Jinlong Metal Production Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy