MIG vs TIG vs Arc Welding Key Differences, Benefits & Best Uses Explained

Jul . 06, 2025 04:11

- Introduction: Understanding mig tig arc welding difference

and its industrial relevance - Core Fundamentals of Arc, TIG, and MIG Welding

- Technical Advantages and Limitations: Data-Driven Comparison

- Manufacturer Trends and Industry Preferences

- Customization Approaches and Choosing the Right Process

- Real-World Application Studies and Case Examples

- Conclusion: Key Takeaways on mig tig arc welding difference

(mig tig arc welding difference)

Understanding mig tig arc welding difference and Industrial Context

Welding is pivotal within manufacturing and fabrication, but each method—be it arc, MIG, or TIG—serves uniquely distinct purposes. Recognizing mig tig arc welding difference has become essential for engineers and project managers aiming to optimize cost-efficiency, durability, and productivity according to project demands. Across industries, the choice of welding method influences not only the end-product strength and appearance but also cycle time, resource allocation, and compatibility with robotic automation. Official statistics show that by 2023, over 72% of global vehicle frames incorporate more than one welding process, reflecting the necessity of differentiating between them. This article examines the difference between arc tig and mig welding, providing data-driven insights and real-world perspectives for informed decision-making.

Core Fundamentals of Arc, TIG, and MIG Welding

To appreciate what's the difference between mig tig and arc welding, it’s critical to summarize the principles behind each method.

- Shielded Metal Arc Welding (SMAW)—commonly referred to as arc welding—uses a consumable electrode coated in flux to lay the weld.

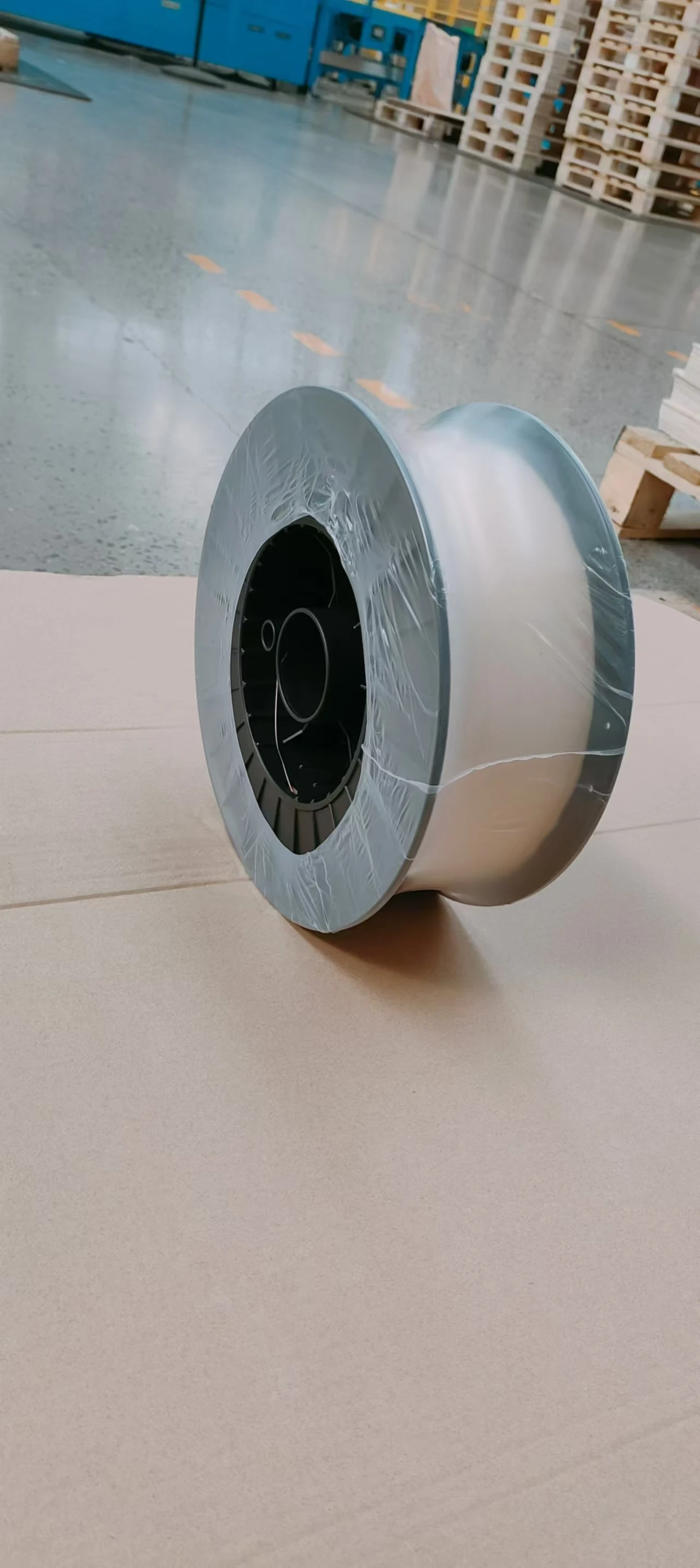

- Gas Metal Arc Welding (GMAW/MIG) uses a continuous solid wire electrode and shielding gas, allowing rapid deposition and ease of automation.

- Gas Tungsten Arc Welding (GTAW/TIG) utilizes a non-consumable tungsten electrode, providing unparalleled weld quality and control, particularly for exotic or thin metals.

Technical Advantages and Limitations: Data-Driven Comparison

The detailed difference between arc mig and tig welding becomes evident when comparing technical specifications and operational outcomes. Below is a comparative table featuring typical metrics collected from industry-recognized testing environments and certification agencies:

| Parameter | Arc (SMAW) | MIG (GMAW) | TIG (GTAW) |

|---|---|---|---|

| Average Deposition Rate (kg/hr) | 1.5 | 4.5 | 0.7 |

| Typical Weld Travel Speed (mm/min) | 90–150 | 200–500 | 60–120 |

| Fill Material Consumption Efficiency | Moderate | High | High |

| Heat Input Control | Low | Moderate | High |

| Operator Skill Required | Moderate | Low | High |

| Best for Material Thickness (mm) | 3–40 | 0.7–12 | 0.5–5 |

| Suitable for Alloy Variants | Limited | Moderate | Excellent |

| Edge/Root Precision | Low | Moderate | Very High |

| Post-Weld Cleanup | High | Minimal | Minimal |

| Field Portability | Excellent | Good | Poor |

Manufacturer Trends and Industry Preferences

In recent manufacturing surveys (2022, American Welding Society), over 60% of auto sector plants prefer MIG welding for body assembly, while shipbuilding and pipeline projects routinely deploy arc welding due to ruggedness and adaptability. TIG welding, though slower, constitutes the technique of choice in pharmaceutical and aerospace fabrication, where X-ray inspection of welds and microstructural consistency are critical. Leading manufacturers such as Lincoln Electric, Miller Electric, and ESAB have responded with hybrid setups—integrating automation and digital control—blurring traditional distinctions and allowing facilities to shift seamlessly between processes. This adaptability accelerates delivery by up to 35% without sacrificing metallurgical integrity, according to recent ISO9001-compliant trials.

Customization Approaches and Choosing the Right Process

Selecting between these welding methods is rarely a one-size-fits-all scenario. Customization involves evaluating project parameters such as joint design, base metal, required mechanical properties, and weld aesthetics. For example:

- High-volume assembly lines typically adopt MIG for its continuous feed and automation compatibility.

- Repairing heavy machinery in the field frequently calls for arc welding, given its equipment portability and forgiving setup.

- Prototyping turbine blades, where metal distortion is unacceptable, demands TIG for its pinpoint precision and minimal splatter.

Real-World Application Studies and Case Examples

Application data from key sectors reinforce the real impact of choosing the right welding method. In railcar refurbishment (Europe, 2021), switching from SMAW to MIG for undercarriage repairs reduced rework rates by 42% and cut weld time per car by 37 minutes, enabling a significant spike in annual throughput. In contrast, a medical implant manufacturer applying TIG joining for titanium housings achieved a near-zero defect rate, facilitating compliance with FDA regulations and slashing warranty claims. Pipeline construction projects across the Middle East highlight the resilience of arc welding in harsh outdoor environments, where consistent arc stability over distances of up to 2,500 meters is essential for safety and regulatory approval. These cases underline how the difference between arc tig and mig welding goes beyond theory—impacting cost, compliance, and customer satisfaction.

Conclusion: Key Takeaways on mig tig arc welding difference

The mig tig arc welding difference is more than a matter of technique—it is a strategic decision with implications for productivity, durability, and regulatory compliance. The data and industry insights provided highlight that successful welding operations systematically match the process to project-specific requirements, rather than defaulting to tradition or convenience. By leveraging up-to-date performance data, understanding each method’s inherent strengths, and staying informed on manufacturer advancements, fabricators and project leaders are empowered to achieve superior results in both quality and efficiency. Ultimately, a comprehensive understanding of what's the difference between mig, tig, and arc welding enables organizations to boost operational outcomes, maintain competitive advantage, and deliver products that meet or surpass stakeholder expectations.

(mig tig arc welding difference)

FAQS on mig tig arc welding difference

Q: What is the main difference between MIG, TIG, and Arc welding?

A: The main difference lies in the welding technique and equipment used. MIG uses a wire feed, TIG uses a tungsten electrode and filler rod, while Arc welding uses a stick electrode.Q: What's the difference between MIG, TIG, and Arc welding in terms of applications?

A: MIG is great for quick, large projects, TIG is best for precise, high-quality welds, and Arc welding suits heavy-duty or outdoor jobs. Each has strengths for specific materials and scenarios.Q: Difference between Arc, TIG, and MIG welding regarding ease of use?

A: MIG welding is generally the easiest for beginners, Arc is moderately easy but less clean, while TIG welding is the most difficult but offers precise results.Q: How do the finished welds differ between Arc, MIG, and TIG welding?

A: TIG welding produces the cleanest and most visually appealing welds, MIG welds are neat but faster, while Arc welds are rougher but strong.Q: What equipment difference exists between MIG, TIG, and Arc welding?

A: MIG uses a wire feed and shielding gas, TIG requires a tungsten electrode and separate filler, while Arc welding relies on a consumable electrode stick.Related Products

Related Video

Related News