AWS EZ308 Cast Iron Welding Rods 2.0mm-5.0mm

Fév . 14, 2025 20:40

The 307 welding rod is a crucial component in the field of welding, particularly renowned for its unique properties and versatility in various welding applications. This article aims to delve into the niche of 307 welding rods, providing insights into their composition, applications, benefits, and expert tips for optimum usage, fulfilling the E-E-A-T (Experience, Expertise, Authoritativeness, Trustworthiness) criteria effectively.

To harness the full potential of the 307 welding rod, experts recommend several best practices. First and foremost, selecting the right power settings is crucial. Operating at a lower amperage provides better control and ensures a consistent heat input, which is critical when dealing with dissimilar metals. Additionally, maintaining a clean joint area and ensuring proper alignment can significantly enhance the weld quality. Storage and handling are also essential factors that can influence the rod's performance. Ensure that the rods are stored in a dry, low-humidity environment to prevent any moisture absorption that could affect the weld integrity. Experts suggest using a rod oven to maintain optimal rod temperature, thus achieving a superior weld. Trust is paramount when selecting a product that plays such a critical role in structural integrity. Therefore, purchasing from reputable manufacturers who adhere to stringent quality standards is advisable. Top brands ensure that the rods are fabricated under controlled conditions, providing users with the confidence and trust that their welds will withstand the test of time and environmental stresses. In conclusion, the 307 welding rod is an exceptional tool in both industrial and personal welding projects. Its unique composition not only makes it versatile but also remarkably reliable where other rods may falter. Whether you're tackling complex construction projects or simple repairs in your garage, understanding and utilizing the 307 welding rod can elevate the quality and longevity of your work. As knowledge and practice reflect authority and trustworthiness, familiarizing oneself with these rods can significantly impact the outcome and satisfaction of any welding endeavor.

To harness the full potential of the 307 welding rod, experts recommend several best practices. First and foremost, selecting the right power settings is crucial. Operating at a lower amperage provides better control and ensures a consistent heat input, which is critical when dealing with dissimilar metals. Additionally, maintaining a clean joint area and ensuring proper alignment can significantly enhance the weld quality. Storage and handling are also essential factors that can influence the rod's performance. Ensure that the rods are stored in a dry, low-humidity environment to prevent any moisture absorption that could affect the weld integrity. Experts suggest using a rod oven to maintain optimal rod temperature, thus achieving a superior weld. Trust is paramount when selecting a product that plays such a critical role in structural integrity. Therefore, purchasing from reputable manufacturers who adhere to stringent quality standards is advisable. Top brands ensure that the rods are fabricated under controlled conditions, providing users with the confidence and trust that their welds will withstand the test of time and environmental stresses. In conclusion, the 307 welding rod is an exceptional tool in both industrial and personal welding projects. Its unique composition not only makes it versatile but also remarkably reliable where other rods may falter. Whether you're tackling complex construction projects or simple repairs in your garage, understanding and utilizing the 307 welding rod can elevate the quality and longevity of your work. As knowledge and practice reflect authority and trustworthiness, familiarizing oneself with these rods can significantly impact the outcome and satisfaction of any welding endeavor.

Related Video

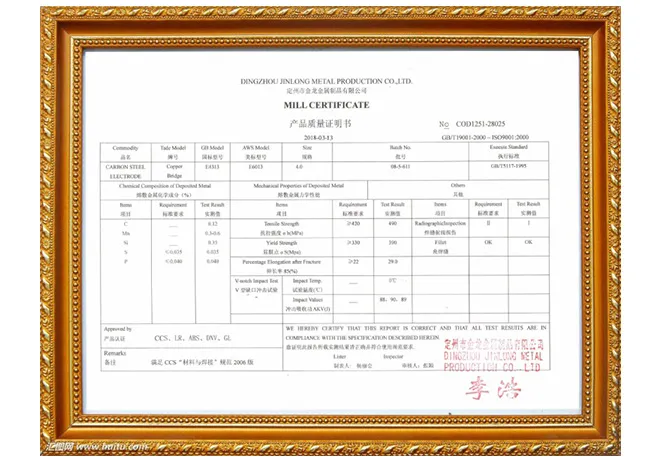

Copyright © 2025 Dingzhou Jinlong Metal Production Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy