Welding Rod 6013 Price per Kg – Affordable Quality Electrodes for Efficient Welding

Jul . 04, 2025 09:08

- Overview of Welding Rod 6013 Pricing Trends and Definitions

- Technical Advantages of Welding Rod 6013 Compared to Alternatives

- Market Price Comparison: Per Kilogram and Per Piece

- Manufacturers and Brand Analysis: Global vs. Regional Choices

- Customized Welding Rod Solutions and Procurement Strategies

- Real-World Case Studies and Industry Applications

- Conclusion: Optimizing Welding Rod 6013 Price Per Kg Investments

(welding rod 6013 price per kg)

Welding Rod 6013 Price Per Kg: Definition, Trends, and Influencing Factors

The welding rod 6013 price per kg

has become a focal point for manufacturers, distributors, and fabrication professionals. Understanding what influences the price per kilogram of 6013 welding rods is critical for effective budgeting and procurement. Historically, the average global welding rod price per kg for type 6013 has fluctuated between $1.30 and $2.10, largely due to shifts in raw material costs, regional taxation, and demand spikes. According to industry tracking, between 2020 and 2023, global demand increased by 8%, leading to a steady yet moderate price escalation.

The price per piece of welding rods is also a relevant metric, especially for small-scale buyers. While bulk purchasers focus on per kg rates, smaller workshops monitor per piece costs to control inventory and minimize waste. It’s important to note that the price structure is influenced by coating thickness, manufacturing standards (AWS, ISO), and packaging type. As automation in the welding sector grows, end-users are increasingly seeking clarity on both per kg and per piece valuations to optimize their production costs and enhance supply chain management.

Technical Advantages of 6013 Welding Electrodes

6013 welding rods are renowned for their smooth arc characteristics, easy slag removal, and excellent bead appearance. The core features driving their popularity include a balanced composition of rutile and cellulose, making them ideal for both AC and DC power sources. A 6013 rod typically provides a tensile strength of 60,000 psi and supports all-position welding, which adds superior flexibility compared to 7018 or 6011 rods.

In terms of operational efficiency, the 6013 model exhibits a deposition rate of around 90 g/min under optimal conditions. This allows for faster workflow in structural steel fabrication, pipe fitting, and general repair work. The rods’ low spatter characteristics mean less post-weld cleaning, further reducing overall project costs. For many industries, the technical edge of the 6013 rod justifies its modest premium, as reflected in the welding rod 6013 price per kg compared to standard alternatives.

Welding Rod Price Comparison: Per Kg and Per Piece

To make informed purchasing decisions, buyers need rigorous data on welding rod price per kg and per piece across the most trusted suppliers. Below is a market survey table reflecting typical price ranges observed in Q1 2024 for both bulk and smaller orders:

| Supplier | Country | 6013 Price Per Kg (USD) | Price Per Piece (USD) | Minimum Order Quantity | Quality Certification |

|---|---|---|---|---|---|

| Lincoln Electric | USA | 2.05 | 0.095 | 100 kg | AWS / ISO |

| ESAB | Sweden | 1.98 | 0.090 | 50 kg | AWS / ISO |

| Bohler Welding | Austria | 2.20 | 0.105 | 200 kg | EN ISO |

| Phoenix | India | 1.45 | 0.068 | 20 kg | ISI |

| Kobelco | Japan | 2.15 | 0.097 | 100 kg | JIS / AWS |

| Local Distributor | South Africa | 1.80 | 0.081 | 10 kg | N/A |

This comparison demonstrates the price variance based on origin, certification, and order volume. For instance, Indian suppliers generally offer the lowest welding rod 6013 price per kg, albeit at lower minimum order sizes and sometimes varying quality verification. Established Western brands tend to be more expensive, reflecting strict adherence to international quality norms.

Major Manufacturers: Global Versus Regional Supplier Assessment

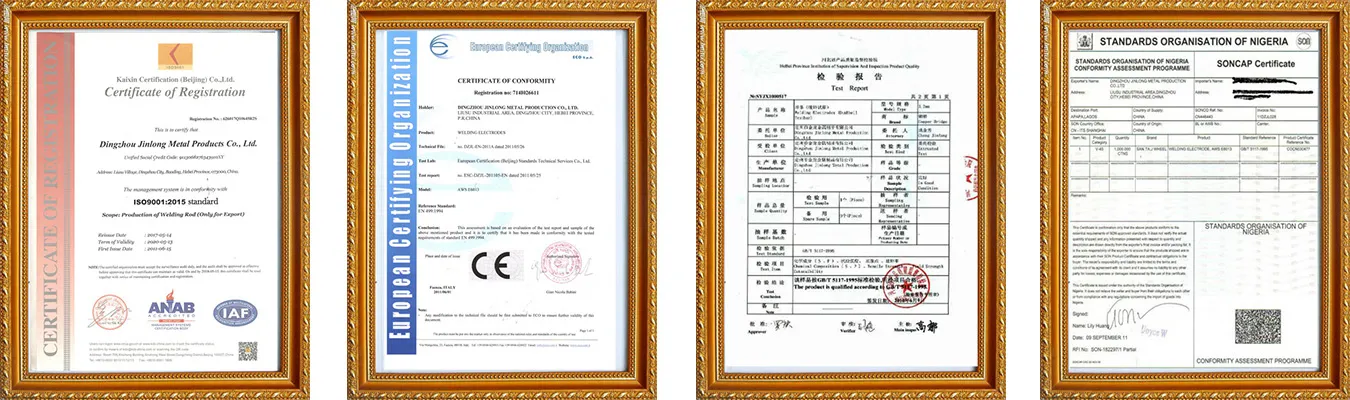

Selecting the right supplier is pivotal for consistent weld quality and economic efficiency. Global manufacturers such as Lincoln Electric and ESAB command strong reputations for quality assurance and comprehensive certification. Their products often cater to large-scale projects where traceability and conformity matter most. Conversely, regional suppliers, particularly throughout Asia and Africa, cater to cost-sensitive markets where price and local support outweigh global branding.

For instance, Phoenix in India provides tailored batches with satisfactory mechanical properties, with a welding rod price per kg undercutting international giants by up to 20%. In contrast, Japanese and European brands offer innovations in flux technology, moisture resistance, and extended shelf life, especially important for safety-critical applications. Knowing the advantages and limitations of each manufacturer segment allows buyers to match their procurement strategy with their technical requirements and budget constraints.

Customized Solutions and Strategic Procurement

Meeting specific application needs often requires customized welding rod solutions or special procurement terms. Suppliers may offer private labeling, bespoke packaging, or adjusted rod lengths/diameters. Strategic partners can provide rapid delivery plans, flexible payment terms, and after-sales technical support.

Data indicates that companies negotiating annual contracts achieve average savings of 8-12% on welding rod 6013 price per kg versus spot-buy scenarios. Furthermore, aligning order schedules with market commodity cycles helps buyers evade seasonal or trend-based price upticks. Procurement professionals are also integrating digital ERP platforms to monitor rod consumption and trigger timely replenishments, thereby reducing emergency purchase premiums.

Application Cases: Welding Rod 6013 in Action

In the field, the 6013 electrode finds wide use across automotive repair, shipbuilding, construction, and pipeline maintenance. For example, a major infrastructure project in Southeast Asia required high-volume, on-site welding under variable weather conditions. Opting for a domestically sourced 6013 rod with a lower price per piece enabled the project to maintain both budget and quality adherence, realizing an 11% reduction in annual weld rod expenditure.

Another industrial case involved a European locomotive manufacturer, which needed enhanced bead aesthetics and minimal spatter for visible welds. By selecting an Austrian high-grade ISO-certified welding rod, the firm realized a 20% reduction in rework time, offsetting the initially higher welding rod price per kg through operational efficiencies. These case studies reinforce the importance of strategic selection beyond mere pricing.

Conclusion: Optimizing Welding Rod 6013 Price Per Kg Investments

Securing the optimal welding rod 6013 price per kg demands a blend of technical knowledge, market insight, and strategic supplier engagement. Be it evaluating global versus regional sources, negotiating bulk contracts, or deploying digital purchasing tools, every aspect plays a role in achieving cost-effectiveness. By considering both per kg and per piece metrics and leveraging manufacturer strengths, industry stakeholders can align quality, productivity, and budget objectives efficiently. Staying updated with global price trends and making informed, data-driven decisions will ensure operational continuity and competitive edge in an evolving market landscape.

(welding rod 6013 price per kg)

FAQS on welding rod 6013 price per kg

Q: What is the current welding rod 6013 price per kg?

A: The welding rod 6013 price per kg typically ranges from $2 to $5, depending on the brand and region. Prices may vary with bulk purchases or market fluctuations.Q: How much does one welding rod cost if bought per piece?

A: The price per piece for a welding rod usually ranges from $0.10 to $0.30. The actual cost depends on the diameter and manufacturer.Q: Are there discounts for buying welding rod 6013 in bulk per kg?

A: Yes, many suppliers offer lower prices per kg for bulk purchases of welding rod 6013. It's best to check with local distributors for specific deals.Q: How does the 6013 welding rod price per kg compare with other types?

A: The 6013 welding rod is generally priced competitively, often similar to or slightly less than 7018 rods per kg. Prices can vary based on quality and supplier.Q: Where can I find the best welding rod price per kg online?

A: You can compare welding rod prices per kg on major online marketplaces and industrial supply websites. Look for reviews and bulk order discounts for the best deals.Related Products

Related Video

Related News