welding rod per kg price

Jan . 13, 2025 15:21

Understanding the pricing of welding rods per kilogram is crucial for any welding professional or enthusiast. Welding rods, also known as electrodes, are key consumables in the welding process. Their pricing depends on various factors, including the type, material, brand, and geographical location.

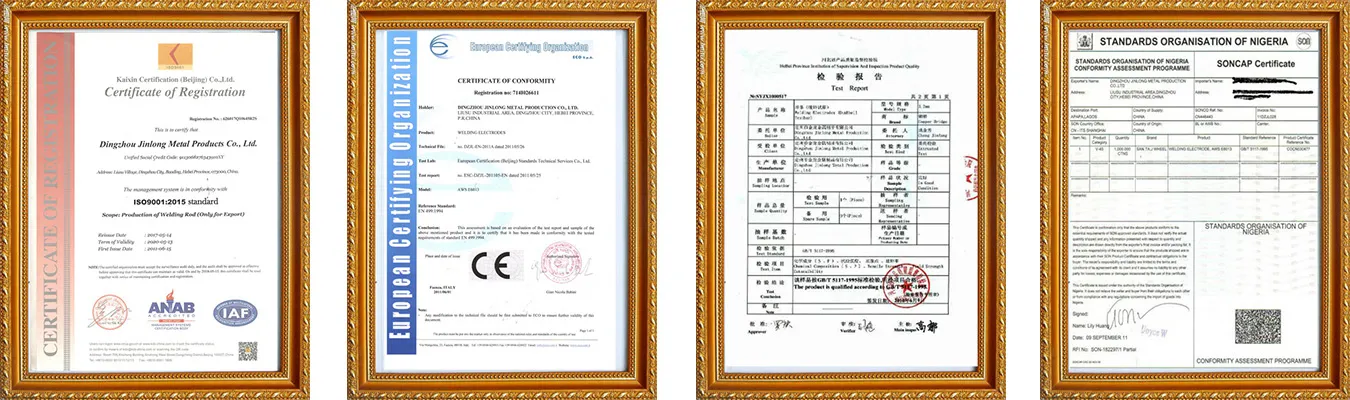

Geographically, prices can vary significantly. Import duties, local taxes, and transportation costs all impact final prices in different regions. For instance, in regions with thriving manufacturing hubs, competition can drive prices down, whereas remote areas might experience heightened prices due to increased logistical costs. Purchasing in bulk can be a cost-effective strategy. Suppliers often offer discounts for large orders, especially for businesses that require consistent supplies. Establishing a long-term relationship with a supplier could also lead to better negotiations and financial terms. It's essential to factor in the specific needs of your projects when selecting welding rods. Parameters such as tensile strength, ductility, corrosion resistance, and specific application suitability must guide your purchasing decision. Engaging with a welding material expert or a seasoned supplier can provide invaluable insights into these factors, ensuring that your purchase aligns perfectly with your performance expectations. Trustworthiness is fundamental when sourcing welding rods. Counterfeit or substandard products, though cheaper, can lead to compromised weld integrity and, subsequently, greater costs due to rework or repairs. Always verify the authenticity of the product and the credibility of the seller. Look for certifications and reviews from other users to guide your choice. In summary, understanding the price dynamics of welding rods requires careful consideration of material types, brand reputation, regional factors, and specific project needs. When integrated with a strategic purchasing approach and expert consultation, these insights can significantly enhance decision-making, ensuring that quality and cost-effectiveness are maintained in your welding operations.

Geographically, prices can vary significantly. Import duties, local taxes, and transportation costs all impact final prices in different regions. For instance, in regions with thriving manufacturing hubs, competition can drive prices down, whereas remote areas might experience heightened prices due to increased logistical costs. Purchasing in bulk can be a cost-effective strategy. Suppliers often offer discounts for large orders, especially for businesses that require consistent supplies. Establishing a long-term relationship with a supplier could also lead to better negotiations and financial terms. It's essential to factor in the specific needs of your projects when selecting welding rods. Parameters such as tensile strength, ductility, corrosion resistance, and specific application suitability must guide your purchasing decision. Engaging with a welding material expert or a seasoned supplier can provide invaluable insights into these factors, ensuring that your purchase aligns perfectly with your performance expectations. Trustworthiness is fundamental when sourcing welding rods. Counterfeit or substandard products, though cheaper, can lead to compromised weld integrity and, subsequently, greater costs due to rework or repairs. Always verify the authenticity of the product and the credibility of the seller. Look for certifications and reviews from other users to guide your choice. In summary, understanding the price dynamics of welding rods requires careful consideration of material types, brand reputation, regional factors, and specific project needs. When integrated with a strategic purchasing approach and expert consultation, these insights can significantly enhance decision-making, ensuring that quality and cost-effectiveness are maintained in your welding operations.

Related Products

Related Video

Related News

Copyright © 2025 Dingzhou Jinlong Metal Production Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy