Stainless Steel Electrodes E316l-16

Feb . 17, 2025 13:46

The e316l 16 welding rod has established itself as a crucial component in the world of welding, particularly for professionals dealing with stainless steel projects. With its specialized composition, this welding rod offers a range of benefits that differentiate it from other options, making it indispensable for both novice and seasoned welders.

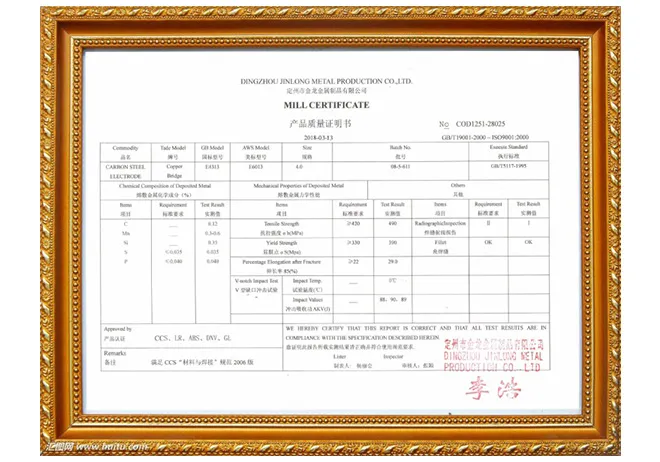

Welders often praise the e316l 16 welding rod for its smooth operational qualities. The ease of strike and re-strike, coupled with minimal spatter, allows for clean, efficient work. This results in aesthetically pleasing welds, which is a significant consideration for exposed joints in projects such as ornamental structures or consumer-facing installations. From an expertise standpoint, selecting the e316l 16 welding rod involves recognizing its specific capabilities and aligning them with project requirements. Welders must consider factors such as the thickness of the materials, the position of welding, and the required mechanical properties of the final product to maximize the effectiveness of this rod. Guidance from seasoned welders and consulting with technical datasheets can aid in making informed decisions tailored to individual project needs. As industry standards advance, the demand for materials that deliver exceptional performance under demanding conditions grows. The e316l 16 welding rod's established reputation as a reliable, high-performance option continues to make it a sought-after choice. Its consistency and quality control are accredited by various international standards, further cementing its status as a trustworthy component in critical applications. In terms of authoritativeness and trustworthiness, the e316l 16 welding rod is backed by numerous certifications that attest to its quality and safety standards. Manufacturers of this rod often undergo stringent quality assurance processes and hold relevant certifications like ISO 9001. These credentials reassure users of the product's integrity, aligning with both industry benchmarks and legal requirements. In conclusion, the e316l 16 welding rod is more than just a tool—it is a centerpiece in the art and science of welding. Its unique composition and properties offer solutions to complex challenges across various sectors, making it a preferred choice for professionals seeking reliability and excellence in their craft. Whether you're dealing with the harsh environments of an industrial complex or the detailed requirements of architectural projects, the e316l 16 welding rod stands out as an exemplary product that delivers on its promises. For those in search of a welding solution that harmoniously blends performance with dependability, this rod symbolizes the epitome of quality.

Welders often praise the e316l 16 welding rod for its smooth operational qualities. The ease of strike and re-strike, coupled with minimal spatter, allows for clean, efficient work. This results in aesthetically pleasing welds, which is a significant consideration for exposed joints in projects such as ornamental structures or consumer-facing installations. From an expertise standpoint, selecting the e316l 16 welding rod involves recognizing its specific capabilities and aligning them with project requirements. Welders must consider factors such as the thickness of the materials, the position of welding, and the required mechanical properties of the final product to maximize the effectiveness of this rod. Guidance from seasoned welders and consulting with technical datasheets can aid in making informed decisions tailored to individual project needs. As industry standards advance, the demand for materials that deliver exceptional performance under demanding conditions grows. The e316l 16 welding rod's established reputation as a reliable, high-performance option continues to make it a sought-after choice. Its consistency and quality control are accredited by various international standards, further cementing its status as a trustworthy component in critical applications. In terms of authoritativeness and trustworthiness, the e316l 16 welding rod is backed by numerous certifications that attest to its quality and safety standards. Manufacturers of this rod often undergo stringent quality assurance processes and hold relevant certifications like ISO 9001. These credentials reassure users of the product's integrity, aligning with both industry benchmarks and legal requirements. In conclusion, the e316l 16 welding rod is more than just a tool—it is a centerpiece in the art and science of welding. Its unique composition and properties offer solutions to complex challenges across various sectors, making it a preferred choice for professionals seeking reliability and excellence in their craft. Whether you're dealing with the harsh environments of an industrial complex or the detailed requirements of architectural projects, the e316l 16 welding rod stands out as an exemplary product that delivers on its promises. For those in search of a welding solution that harmoniously blends performance with dependability, this rod symbolizes the epitome of quality.

Related Video

Copyright © 2025 Dingzhou Jinlong Metal Production Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy