3/32 welding rod 6011 amperage

Feb . 04, 2025 05:55

Choosing the correct welding rod can be a vital aspect in ensuring strong welds and successful projects, especially when working with a rod like the 6011. As a prominent choice among welders, the 6011 welding rod is known for its versatility and ability to weld on rusted or dirty surfaces, thus requiring a keen understanding of its amperage settings to optimize performance.

To achieve the perfect weld with a 6011 rod, one must also consider the welding technique being utilized. A steadier hand with quick manipulation of the rod can allow for more efficient use of higher amperages without sacrificing control. On the other hand, welders adopting slower, more methodical passes might find better results sticking closer to midpoint amperage settings, allowing for more consistency and reduced risk of overheating. Professional welders often recommend keeping the electrode at a slight angle to the workpiece, a technique that complements the arc characteristics of the 6011 rod. Coupling this technique with tailored amperage ensures the arc maintains stability and ergo, produces a uniform weld bead. Moreover, frequent practice and testing on scrap pieces before embarking on the final project can enhance one's understanding of how the 6011 rod operates under different amperage settings. These efforts provide practical experience, enhancing the welder’s ability to intuitively adjust settings according to evolving project demands. Ultimately, the mastery of the 6011 welding rod and its optimal amperage settings speaks to the heart of welding expertise. Welders who continuously refine their approach to this rod, attentively balancing amperage with technique and project requirements, will undoubtedly develop a more authoritative presence in their craft. As with any professional tool, commitment to thorough understanding and application leads to the reliable, trusted results that are the hallmark of skilled artisans in the welding community.

To achieve the perfect weld with a 6011 rod, one must also consider the welding technique being utilized. A steadier hand with quick manipulation of the rod can allow for more efficient use of higher amperages without sacrificing control. On the other hand, welders adopting slower, more methodical passes might find better results sticking closer to midpoint amperage settings, allowing for more consistency and reduced risk of overheating. Professional welders often recommend keeping the electrode at a slight angle to the workpiece, a technique that complements the arc characteristics of the 6011 rod. Coupling this technique with tailored amperage ensures the arc maintains stability and ergo, produces a uniform weld bead. Moreover, frequent practice and testing on scrap pieces before embarking on the final project can enhance one's understanding of how the 6011 rod operates under different amperage settings. These efforts provide practical experience, enhancing the welder’s ability to intuitively adjust settings according to evolving project demands. Ultimately, the mastery of the 6011 welding rod and its optimal amperage settings speaks to the heart of welding expertise. Welders who continuously refine their approach to this rod, attentively balancing amperage with technique and project requirements, will undoubtedly develop a more authoritative presence in their craft. As with any professional tool, commitment to thorough understanding and application leads to the reliable, trusted results that are the hallmark of skilled artisans in the welding community.

Related Video

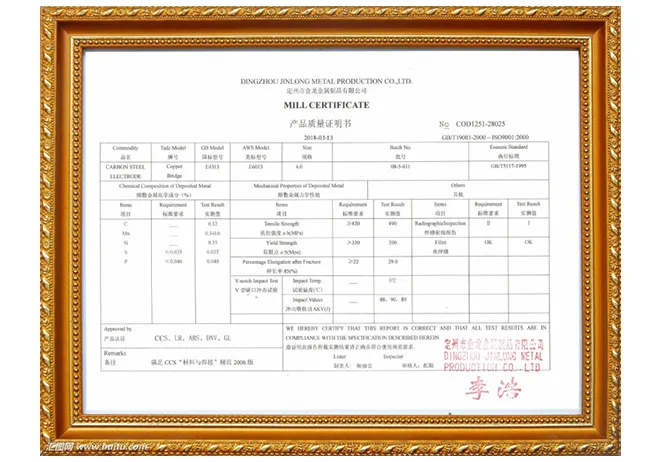

Copyright © 2025 Dingzhou Jinlong Metal Production Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy