AWS EZ308 Cast Iron Welding Rods 2.0mm-5.0mm

Feb . 13, 2025 05:41

Selecting the right welding rod is crucial for achieving optimal results in any welding project. The 308h 16 welding rod is an exceptional choice for professionals seeking durable and high-quality welds, especially when working with stainless steel. This article delves into the specific features and advantages of the 308h 16 welding rod, drawing from expert insights and real-world experiences to provide a comprehensive guide for its application.

Authoritative sources within the welding industry, including manufacturers and welding engineers, consistently recommend the 308h 16 welding rod for projects involving 304H stainless steel applications. Their endorsements are backed by extensive testing and data analysis, underscoring the rod's superior performance in maintaining weld integrity under extreme conditions. Trustworthiness is further reinforced through customer testimonials and case studies that document the endurance and strength of welds produced with the 308h 16 welding rod. Clients using this rod have reported its exceptional longevity and ability to withstand harsh environmental factors, leading to reduced maintenance costs and extended service life of welded components. When selecting welding rods, understanding the specific requirements of your project is essential. The 308h 16 welding rod’s unique properties make it an optimal choice for professionals needing a dependable solution for high-temperature welding applications. By aligning your welding materials with the demands of your job, you ensure not only the success of the project but also the safety and reliability of the structure in its final form. In conclusion, the 308h 16 welding rod stands out as a premier choice for welding professionals, combining high carbon content, versatility, and proven performance. Its effectiveness at high temperatures, ease of use, and reliable results in maintaining weld quality render it indispensable in industries where precision and durability are paramount. Embracing the insights of both experts and users, this welding rod paves the way for enhanced project outcomes and greater client satisfaction.

Authoritative sources within the welding industry, including manufacturers and welding engineers, consistently recommend the 308h 16 welding rod for projects involving 304H stainless steel applications. Their endorsements are backed by extensive testing and data analysis, underscoring the rod's superior performance in maintaining weld integrity under extreme conditions. Trustworthiness is further reinforced through customer testimonials and case studies that document the endurance and strength of welds produced with the 308h 16 welding rod. Clients using this rod have reported its exceptional longevity and ability to withstand harsh environmental factors, leading to reduced maintenance costs and extended service life of welded components. When selecting welding rods, understanding the specific requirements of your project is essential. The 308h 16 welding rod’s unique properties make it an optimal choice for professionals needing a dependable solution for high-temperature welding applications. By aligning your welding materials with the demands of your job, you ensure not only the success of the project but also the safety and reliability of the structure in its final form. In conclusion, the 308h 16 welding rod stands out as a premier choice for welding professionals, combining high carbon content, versatility, and proven performance. Its effectiveness at high temperatures, ease of use, and reliable results in maintaining weld quality render it indispensable in industries where precision and durability are paramount. Embracing the insights of both experts and users, this welding rod paves the way for enhanced project outcomes and greater client satisfaction.

Related Video

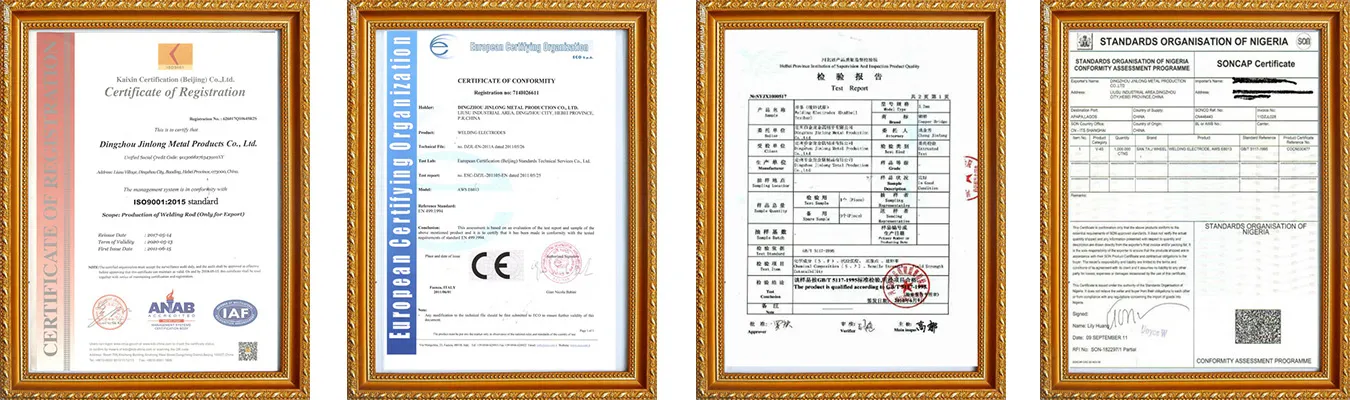

Copyright © 2025 Dingzhou Jinlong Metal Production Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy