basic welding rods

জানু. . 10, 2025 12:57

Basic welding rods are foundational elements in the world of welding, and understanding their characteristics is crucial for achieving strong and durable welds. The true test of any welding process lies not only in the expertise of the welder but also significantly in the quality and suitability of the welding rod selected for the task.

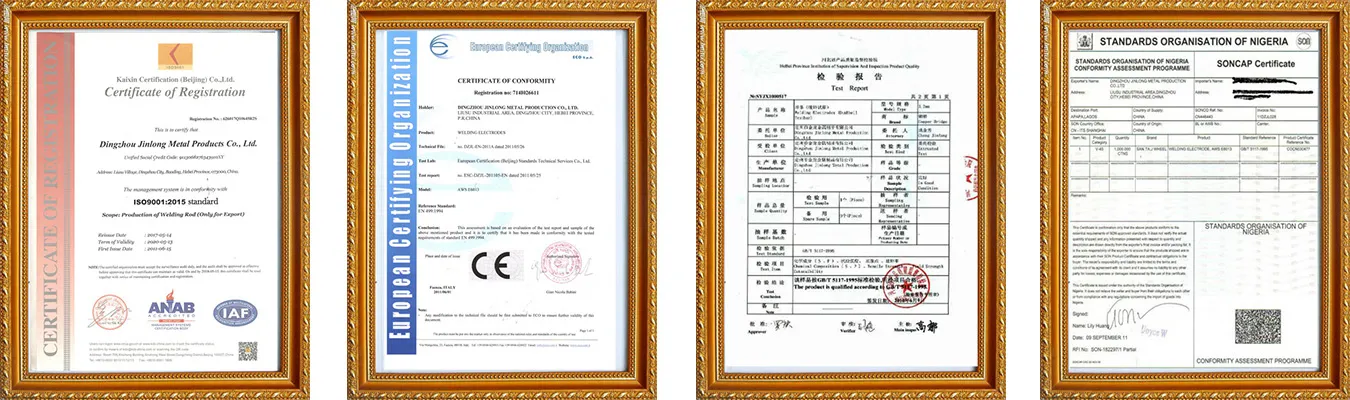

Authoritativeness in the realm of welding rods is backed by adherence to industry standards and certifications. Professional welders rely on rods that meet stringent standards such as those set by the American Welding Society (AWS). This not only ensures quality and reliability but also compliance with safety and performance regulations. Reputable manufacturers often provide rods that are rigorously tested and certified, offering assurance of their performance under specified conditions. Trustworthiness in the selection of welding rods can also significantly affect the outcome of a welding job. It involves sourcing rods from credible manufacturers known for their consistency in quality. Unscrupulous sources may offer cheaper rods, but these often lead to inferior welds that may cause structural failures over time. Investing in high-quality rods from trusted brands ensures fewer defects, reduced rework, and overall cost savings in the long run. In conclusion, the choice of basic welding rods should be informed by a combination of experience, expertise, authority, and trustworthiness. Whether for a large industrial application or a simple DIY project, understanding the nuances of welding rod selection is imperative to achieving a high-quality finish. Professionals in the industry must continually update their knowledge and skills, ensuring that they choose the most suitable and reliable welding rods for their needs, leading to safe, effective, and successful welding operations.

Authoritativeness in the realm of welding rods is backed by adherence to industry standards and certifications. Professional welders rely on rods that meet stringent standards such as those set by the American Welding Society (AWS). This not only ensures quality and reliability but also compliance with safety and performance regulations. Reputable manufacturers often provide rods that are rigorously tested and certified, offering assurance of their performance under specified conditions. Trustworthiness in the selection of welding rods can also significantly affect the outcome of a welding job. It involves sourcing rods from credible manufacturers known for their consistency in quality. Unscrupulous sources may offer cheaper rods, but these often lead to inferior welds that may cause structural failures over time. Investing in high-quality rods from trusted brands ensures fewer defects, reduced rework, and overall cost savings in the long run. In conclusion, the choice of basic welding rods should be informed by a combination of experience, expertise, authority, and trustworthiness. Whether for a large industrial application or a simple DIY project, understanding the nuances of welding rod selection is imperative to achieving a high-quality finish. Professionals in the industry must continually update their knowledge and skills, ensuring that they choose the most suitable and reliable welding rods for their needs, leading to safe, effective, and successful welding operations.

Related Video

Copyright © 2025 Dingzhou Jinlong Metal Production Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy