ss 304 to ms welding electrode

فبراير . 15, 2025 11:07

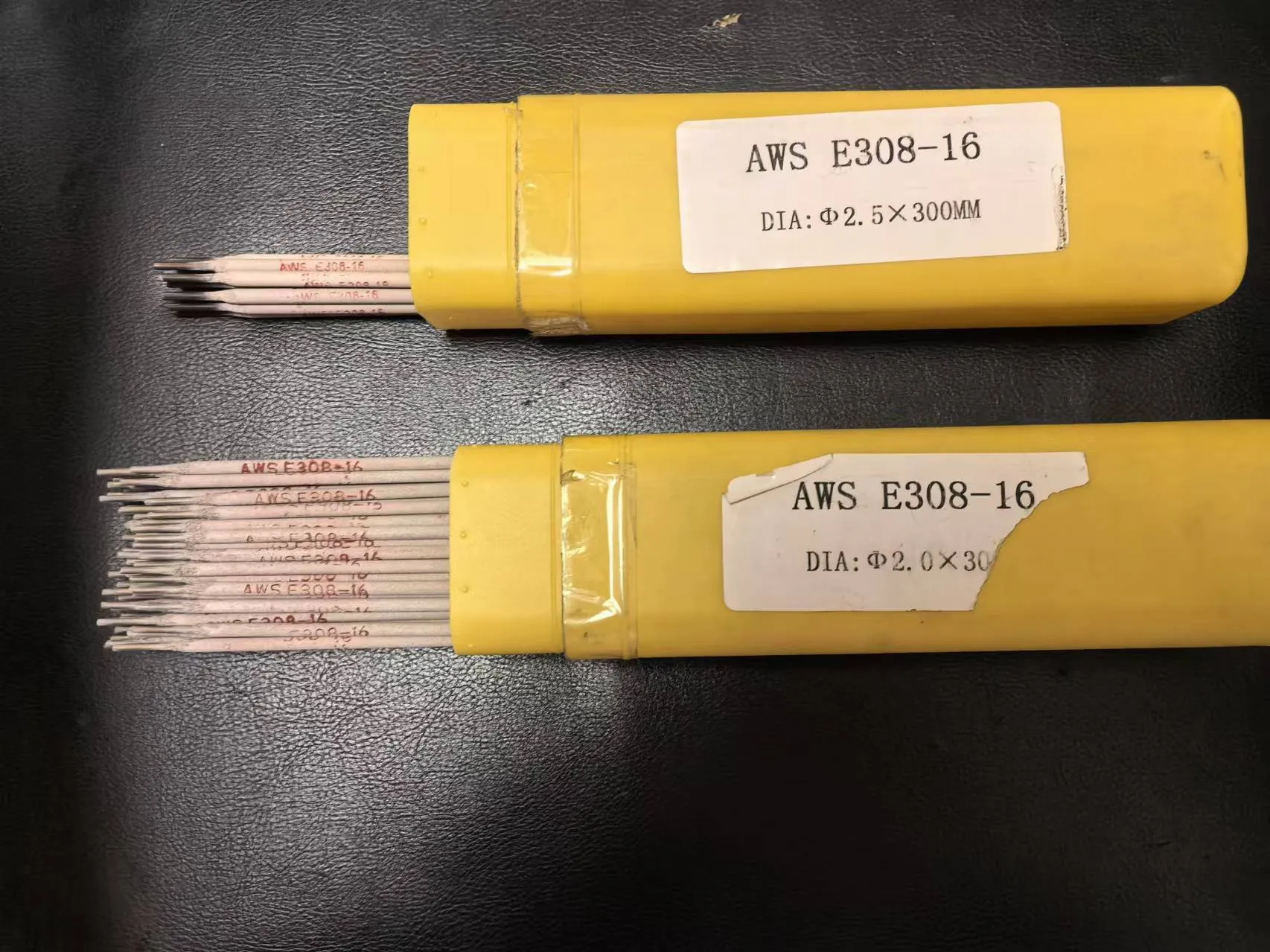

When embarking on a welding project involving the fusion of stainless steel 304 (SS 304) to mild steel (MS), selecting the right electrode is crucial. This seemingly straightforward task requires a deep understanding of the distinctive properties of each metal and the interactions that occur during the welding process. With years of expertise and professional insights, this guide aims to illuminate the technical nuances involved in choosing the appropriate welding electrode for SS 304 to MS.

Technical Execution The welding procedure should include careful control of heat input to prevent overheating either metal, which could lead to warping or burning through. It is vital to calibrate the welding machine settings to match the electrode type, thickness, and position of the weld. Experts recommend using a direct current electrode positive (DCEP) setting for generating the requisite depth of penetration without compromising the base metals. Testing and Verification Post-welding, it is paramount to conduct thorough inspections and non-destructive testing (NDT) to ensure the integrity of the weld. Methods such as radiographic testing (RT) and ultrasonic testing (UT) provide insights into hidden defects that may not be visible to the naked eye. Additionally, a corrosion resistance test may be necessary to ascertain the longevity of the welded joint in corrosive environments. Conclusion A successful weld between SS 304 and MS hinges on a comprehensive understanding of the underlying metallurgical principles, meticulous electrode selection, and proficient execution. Prioritizing these factors not only ensures a robust, durable joint but also enhances the overall quality and lifespan of the welded structure. Trust in professional expertise and authoritative guidance is essential to achieving excellence in welding projects involving dissimilar metals. By drawing on the wealth of practical experience and technical know-how, this guide empowers you to make informed decisions and tackle complex welding challenges with confidence and precision.

Technical Execution The welding procedure should include careful control of heat input to prevent overheating either metal, which could lead to warping or burning through. It is vital to calibrate the welding machine settings to match the electrode type, thickness, and position of the weld. Experts recommend using a direct current electrode positive (DCEP) setting for generating the requisite depth of penetration without compromising the base metals. Testing and Verification Post-welding, it is paramount to conduct thorough inspections and non-destructive testing (NDT) to ensure the integrity of the weld. Methods such as radiographic testing (RT) and ultrasonic testing (UT) provide insights into hidden defects that may not be visible to the naked eye. Additionally, a corrosion resistance test may be necessary to ascertain the longevity of the welded joint in corrosive environments. Conclusion A successful weld between SS 304 and MS hinges on a comprehensive understanding of the underlying metallurgical principles, meticulous electrode selection, and proficient execution. Prioritizing these factors not only ensures a robust, durable joint but also enhances the overall quality and lifespan of the welded structure. Trust in professional expertise and authoritative guidance is essential to achieving excellence in welding projects involving dissimilar metals. By drawing on the wealth of practical experience and technical know-how, this guide empowers you to make informed decisions and tackle complex welding challenges with confidence and precision.

Related Video

Copyright © 2025 Dingzhou Jinlong Metal Production Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy