is 1/8 bigger than 3/32 welding rod

فبراير . 07, 2025 04:33

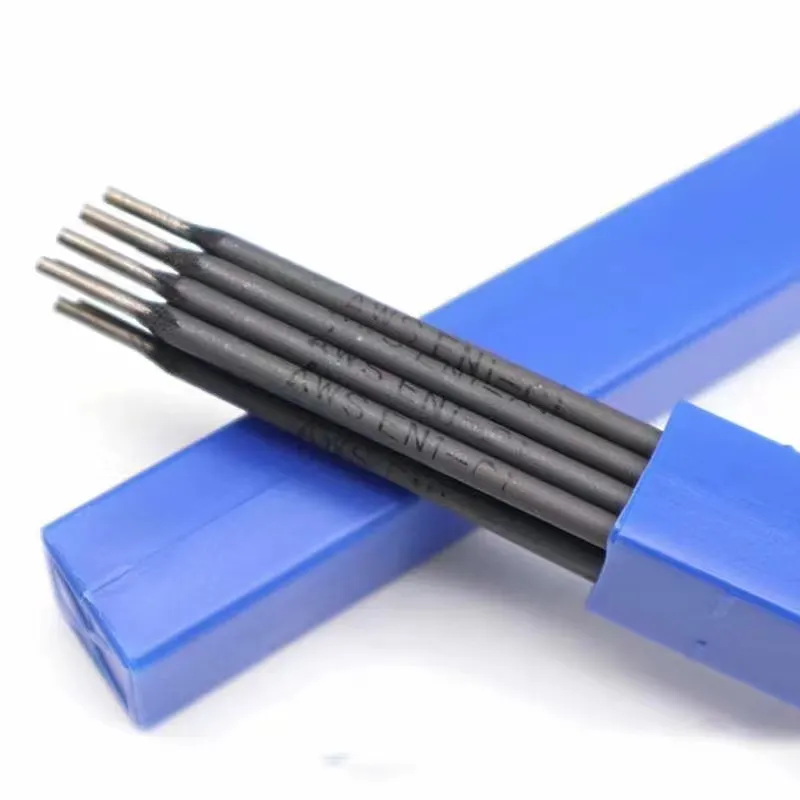

When choosing the correct welding rod size, understanding fractions and their implications is paramount for ensuring successful welds. Among the frequently debated sizes are the 1/8 inch and the 3/32 inch rods. Is 1/8 truly bigger than 3/32? Let’s delve into the details, exploring from an experienced welder's perspective and backed by welding expertise.

Through authoritative training and hands-on expertise, welders also understand the influence of rod size on productivity. Larger rods decrease the number of passes needed to complete a weld, thus saving time during extensive projects. Nonetheless, smaller rods afford greater maneuverability, allowing for complex weld geometries. The expert eye evaluates these trade-offs, ensuring the chosen rod accommodates both the material and the welder's proficiency. Furthermore, the welding process itself dictates rod choice. For instance, in stick welding (SMAW), where conditions often include outdoor or windy environments, a 1/8 inch rod might offer a stable arc and better deposition rate. Conversely, for TIG welding processes demanding precision, a welder might favor a smaller diameter like the 3/32 inch to achieve a fine, controlled welde line without overwhelming the workpiece. The importance of welding rod size cannot be understated, and the decision should stem from a foundation of knowledge, sanctioned by authoritative guides like the American Welding Society (AWS) and trusted welding manuals. When selecting the appropriate size, consider material thickness, welding position, and desired penetration. Welding professionals rely on well-documented standards and personal experience to make informed decisions. In conclusion, understanding whether 1/8 is bigger than 3/32 is just the beginning. The implications of this size differentiation can drastically alter the landscape of a welding project. Welding experts, with years of experience and trustworthiness in the field, continuously refine their techniques, drawing from an authoritative knowledge base to ensure that every weld is not just a mechanical bond, but a blend of art and science that lasts through the ages. So, when it comes to choosing between 1/8 and 3/32 inch rods, remember that size is indeed significant—but it’s how you apply it that truly matters.

Through authoritative training and hands-on expertise, welders also understand the influence of rod size on productivity. Larger rods decrease the number of passes needed to complete a weld, thus saving time during extensive projects. Nonetheless, smaller rods afford greater maneuverability, allowing for complex weld geometries. The expert eye evaluates these trade-offs, ensuring the chosen rod accommodates both the material and the welder's proficiency. Furthermore, the welding process itself dictates rod choice. For instance, in stick welding (SMAW), where conditions often include outdoor or windy environments, a 1/8 inch rod might offer a stable arc and better deposition rate. Conversely, for TIG welding processes demanding precision, a welder might favor a smaller diameter like the 3/32 inch to achieve a fine, controlled welde line without overwhelming the workpiece. The importance of welding rod size cannot be understated, and the decision should stem from a foundation of knowledge, sanctioned by authoritative guides like the American Welding Society (AWS) and trusted welding manuals. When selecting the appropriate size, consider material thickness, welding position, and desired penetration. Welding professionals rely on well-documented standards and personal experience to make informed decisions. In conclusion, understanding whether 1/8 is bigger than 3/32 is just the beginning. The implications of this size differentiation can drastically alter the landscape of a welding project. Welding experts, with years of experience and trustworthiness in the field, continuously refine their techniques, drawing from an authoritative knowledge base to ensure that every weld is not just a mechanical bond, but a blend of art and science that lasts through the ages. So, when it comes to choosing between 1/8 and 3/32 inch rods, remember that size is indeed significant—but it’s how you apply it that truly matters.

Related Products

Related Video

Related News

Copyright © 2025 Dingzhou Jinlong Metal Production Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy