Oxidation-Corrosion-Resistant Cast Iron Welding Alloy Nife-1

فبراير . 13, 2025 04:12

Choosing the right materials for a welding project is crucial to ensuring durability, efficiency, and safety. One of the most reliable options for many industrial and personal projects is the 1.6 mm stainless steel welding rod. These rods have garnered popularity due to their versatility, strength, and suitability for various applications.

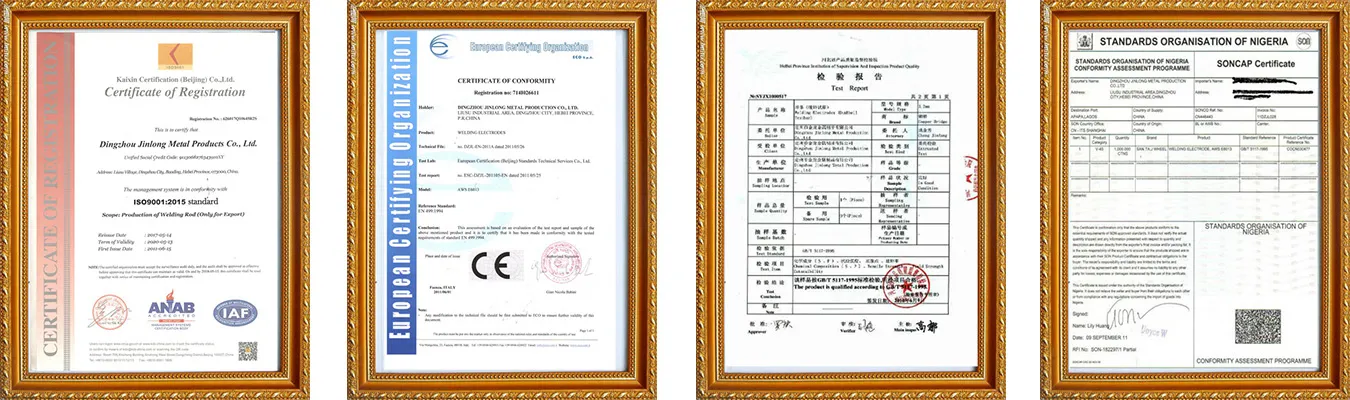

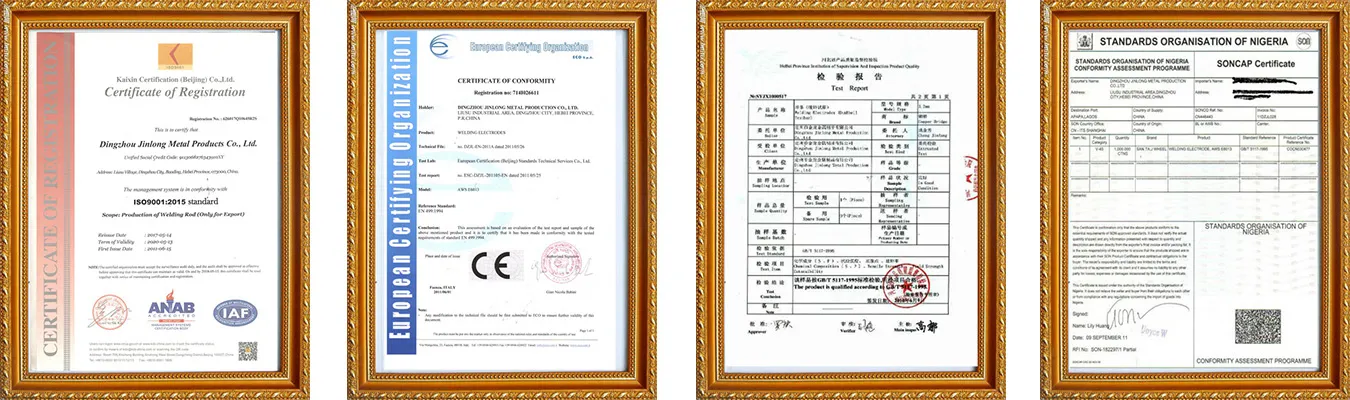

5. Safety and Technical Expertise Professional welding involves not just skill but also adherence to safety standards. When using 1.6 mm stainless steel welding rods, it's critical to ensure proper ventilation, as welding can produce fumes that might be harmful if inhaled. Wearing the appropriate protective gear, such as gloves, helmets, and eye protection, is also essential in preventing injuries. Furthermore, welders need to be adept in setting the correct parameters on their equipment. The current setting, which influences penetration depth and welding speed, must be finely tuned to the specifications of the rods and the materials being welded. This technical knowledge differentiates expert welders from novices. 6. Enhancing Trust through Certification and Testing The authority of any product, particularly in the realm of welding, is bolstered by rigorous testing and certification. 1.6 mm stainless steel welding rods adhere to stringent international standards such as those set by the American Welding Society (AWS). Products with certifications offer a guarantee of quality and reliability, ensuring that they meet the performance demands of various applications. 7. Building Trust and Reliability For both suppliers and consumers, building trust in 1.6 mm stainless steel welding rods comes from consistent quality and performance. Suppliers should ensure that their products come with comprehensive information and support, guiding users through proper usage, maintenance, and troubleshooting. Consumers, on the other hand, should seek testimonials and reviews from fellow users to confidently choose products that deliver on their promises. In conclusion, the choice of 1.6 mm stainless steel welding rods can profoundly impact the quality and longevity of welded structures. Understanding their composition, applications, and the technical expertise required to use them positions these rods as a top-tier choice for both professional and hobbyist welders. Through certification and community trust, these welding rods continue to uphold their reputation in the demanding world of metal fabrication.

5. Safety and Technical Expertise Professional welding involves not just skill but also adherence to safety standards. When using 1.6 mm stainless steel welding rods, it's critical to ensure proper ventilation, as welding can produce fumes that might be harmful if inhaled. Wearing the appropriate protective gear, such as gloves, helmets, and eye protection, is also essential in preventing injuries. Furthermore, welders need to be adept in setting the correct parameters on their equipment. The current setting, which influences penetration depth and welding speed, must be finely tuned to the specifications of the rods and the materials being welded. This technical knowledge differentiates expert welders from novices. 6. Enhancing Trust through Certification and Testing The authority of any product, particularly in the realm of welding, is bolstered by rigorous testing and certification. 1.6 mm stainless steel welding rods adhere to stringent international standards such as those set by the American Welding Society (AWS). Products with certifications offer a guarantee of quality and reliability, ensuring that they meet the performance demands of various applications. 7. Building Trust and Reliability For both suppliers and consumers, building trust in 1.6 mm stainless steel welding rods comes from consistent quality and performance. Suppliers should ensure that their products come with comprehensive information and support, guiding users through proper usage, maintenance, and troubleshooting. Consumers, on the other hand, should seek testimonials and reviews from fellow users to confidently choose products that deliver on their promises. In conclusion, the choice of 1.6 mm stainless steel welding rods can profoundly impact the quality and longevity of welded structures. Understanding their composition, applications, and the technical expertise required to use them positions these rods as a top-tier choice for both professional and hobbyist welders. Through certification and community trust, these welding rods continue to uphold their reputation in the demanding world of metal fabrication.

Related Video

Copyright © 2025 Dingzhou Jinlong Metal Production Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy