Aluminum Magnesium 5356 Aluminum Alloy Argon Arc Welding Wire

فبراير . 13, 2025 03:39

For professionals and DIY enthusiasts alike, choosing the right welding rod is a critical part of ensuring a successful project. The 1.6 mm stainless steel arc welding rods are an exceptional choice for those aiming for precision and robust results in their welding undertakings. These rods, often referred to as filler metals in the industry, play a pivotal role in determining the strength, durability, and appearance of the welds they create. In this exploration, we delve into why these particular rods stand out in the world of welding, backed by expertise and trusted practices.

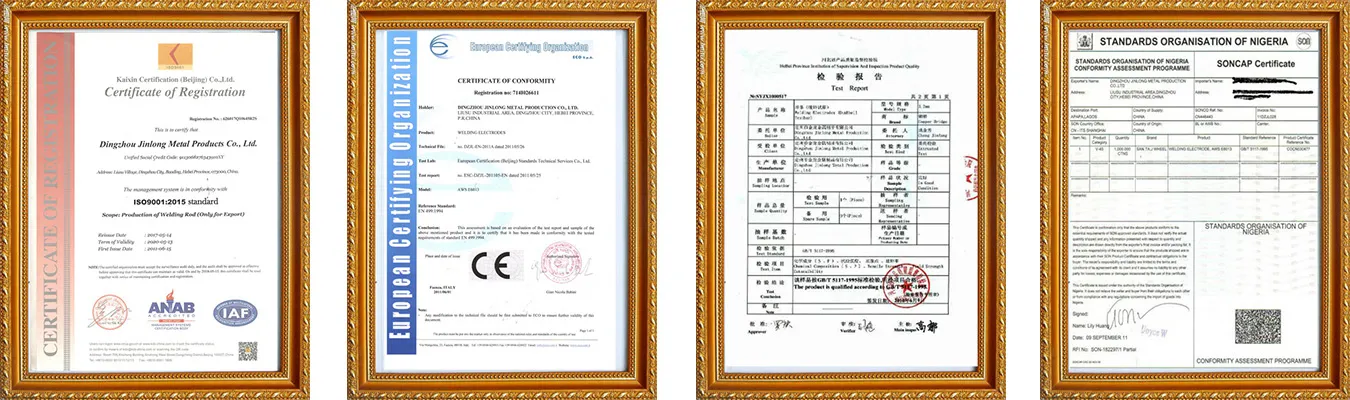

Trustworthiness in any tool or component is not just about the immediate results but also the long-term reliability. 1.6 mm stainless steel arc welding rods deliver on this front with evidence of outstanding metallurgical properties and proven longevity. They maintain their integrity under thermal cycling conditions – a common challenge in welding operations – which speaks volumes about their durability. Furthermore, the environmental friendliness of stainless steel makes these rods a preferred choice for eco-conscious projects. Stainless steel is fully recyclable, which reduces wastage in the long run. Welding projects that align with sustainable practices not only benefit the environment but also enhance a company's corporate image, resonating well with modern consumers and regulatory requirements. Quality assurance is of paramount importance; therefore, acquiring these rods from reputable manufacturers ensures compliance with international standards. Organizations such as the American Welding Society (AWS) and the International Organization for Standardization (ISO) provide certifications that signify adherence to rigorous quality checks, providing welders with peace of mind regarding the materials they are employing. In summary, 1.6 mm stainless steel arc welding rods are a vital asset for any welding professional dedicated to quality, efficiency, and reliability. Their broad applicability across various projects, the intrinsic strength of stainless steel, and proven performance metrics place them at the forefront of welding choices. By combining cutting-edge technology with classic welding techniques, these rods are a testament to the evolution and future of metal fabrication.

Trustworthiness in any tool or component is not just about the immediate results but also the long-term reliability. 1.6 mm stainless steel arc welding rods deliver on this front with evidence of outstanding metallurgical properties and proven longevity. They maintain their integrity under thermal cycling conditions – a common challenge in welding operations – which speaks volumes about their durability. Furthermore, the environmental friendliness of stainless steel makes these rods a preferred choice for eco-conscious projects. Stainless steel is fully recyclable, which reduces wastage in the long run. Welding projects that align with sustainable practices not only benefit the environment but also enhance a company's corporate image, resonating well with modern consumers and regulatory requirements. Quality assurance is of paramount importance; therefore, acquiring these rods from reputable manufacturers ensures compliance with international standards. Organizations such as the American Welding Society (AWS) and the International Organization for Standardization (ISO) provide certifications that signify adherence to rigorous quality checks, providing welders with peace of mind regarding the materials they are employing. In summary, 1.6 mm stainless steel arc welding rods are a vital asset for any welding professional dedicated to quality, efficiency, and reliability. Their broad applicability across various projects, the intrinsic strength of stainless steel, and proven performance metrics place them at the forefront of welding choices. By combining cutting-edge technology with classic welding techniques, these rods are a testament to the evolution and future of metal fabrication.

Related Video

Copyright © 2025 Dingzhou Jinlong Metal Production Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy