aws 7018 welding rod

2 月 . 18, 2025 07:24

Welding cast iron using a 7018 rod presents a unique set of challenges, yet it also offers distinct advantages when approached correctly. This type of welding requires careful preparation, a thorough understanding of metallurgical properties, and expert knowledge in adjusting techniques to ensure strong, durable welds.

From an expertise perspective, it is crucial to understand why cracks occur and how the 7018 rod helps alleviate these issues. The ductility of the weld metal deposited by the 7018 rod absorbs more stress and allows for minor movements in the weld area, which accommodates the expansion and contraction commonly experienced in cast iron welding. In terms of equipment and technique, employing a direct current electrode positive (DCEP) setup can improve penetration and fusion, enhancing the weld's integrity. Training and certification in this particular welding process further bolster a welder's credentials, reflecting a deep understanding and authoritative proficiency in managing the complexities that welding cast iron with a 7018 rod involves. Industry experts also emphasize the importance of verifying weld integrity through non-destructive testing methods, such as ultrasonic testing or radiography, to ensure the welds meet safety standards and performance expectations. Professionals in welding highly value these practices as they contribute to the overall trustworthiness of the technique. Finally, it is essential to acknowledge that while the 7018 rod provides a versatile solution, a welder’s skill and knowledge remain paramount. With a combination of proper technique, environmental control, and sophisticated understanding, welding cast iron with a 7018 rod not only becomes feasible but delivers durable joints that withstand operational stresses, bridging the gap between theoretical practice and effective application in the field. By improving product reliability and performance through authoritative, expert application of the 7018 rod, businesses can ensure higher customer satisfaction and solidify their position as trusted providers of high-quality welding solutions.

From an expertise perspective, it is crucial to understand why cracks occur and how the 7018 rod helps alleviate these issues. The ductility of the weld metal deposited by the 7018 rod absorbs more stress and allows for minor movements in the weld area, which accommodates the expansion and contraction commonly experienced in cast iron welding. In terms of equipment and technique, employing a direct current electrode positive (DCEP) setup can improve penetration and fusion, enhancing the weld's integrity. Training and certification in this particular welding process further bolster a welder's credentials, reflecting a deep understanding and authoritative proficiency in managing the complexities that welding cast iron with a 7018 rod involves. Industry experts also emphasize the importance of verifying weld integrity through non-destructive testing methods, such as ultrasonic testing or radiography, to ensure the welds meet safety standards and performance expectations. Professionals in welding highly value these practices as they contribute to the overall trustworthiness of the technique. Finally, it is essential to acknowledge that while the 7018 rod provides a versatile solution, a welder’s skill and knowledge remain paramount. With a combination of proper technique, environmental control, and sophisticated understanding, welding cast iron with a 7018 rod not only becomes feasible but delivers durable joints that withstand operational stresses, bridging the gap between theoretical practice and effective application in the field. By improving product reliability and performance through authoritative, expert application of the 7018 rod, businesses can ensure higher customer satisfaction and solidify their position as trusted providers of high-quality welding solutions.

Related Video

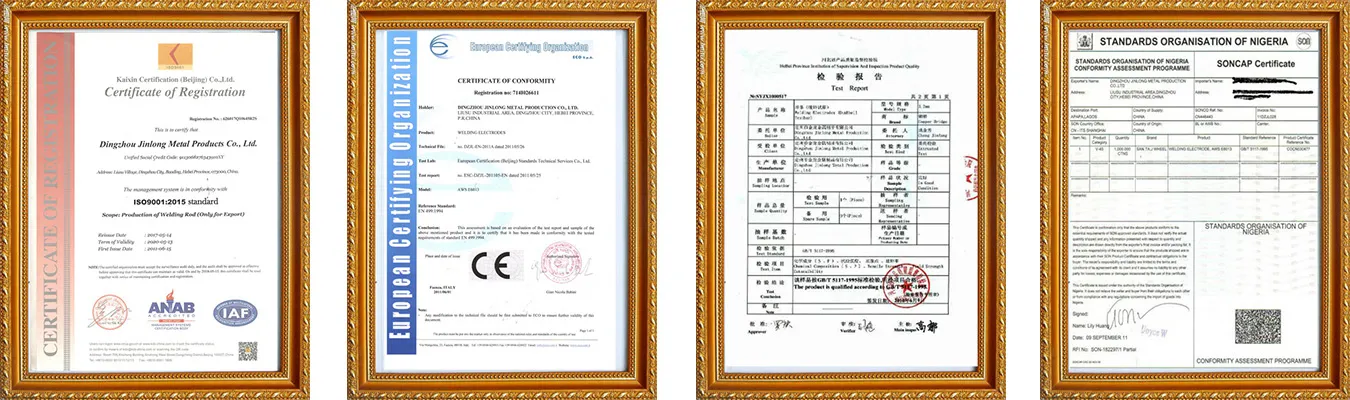

Copyright © 2025 Dingzhou Jinlong Metal Production Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy