Argon Arc Welding Wire – Clean Beads, Low Spatter, Strong

Nov . 06, 2025 07:40

Argon Arc Welding Wire is a key solution in the industrial supplies industry, specifically within Welding supplies and Argon arc welding wire. This article explores how Dingzhou Jinlong Metal Production Co., Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Argon Arc Welding Wire Overview

- Benefits & Use Cases of Argon Arc Welding Wire in Argon arc welding wire

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in industrial supplies

- Conclusion on Argon Arc Welding Wire from Dingzhou Jinlong Metal Production Co., Ltd.

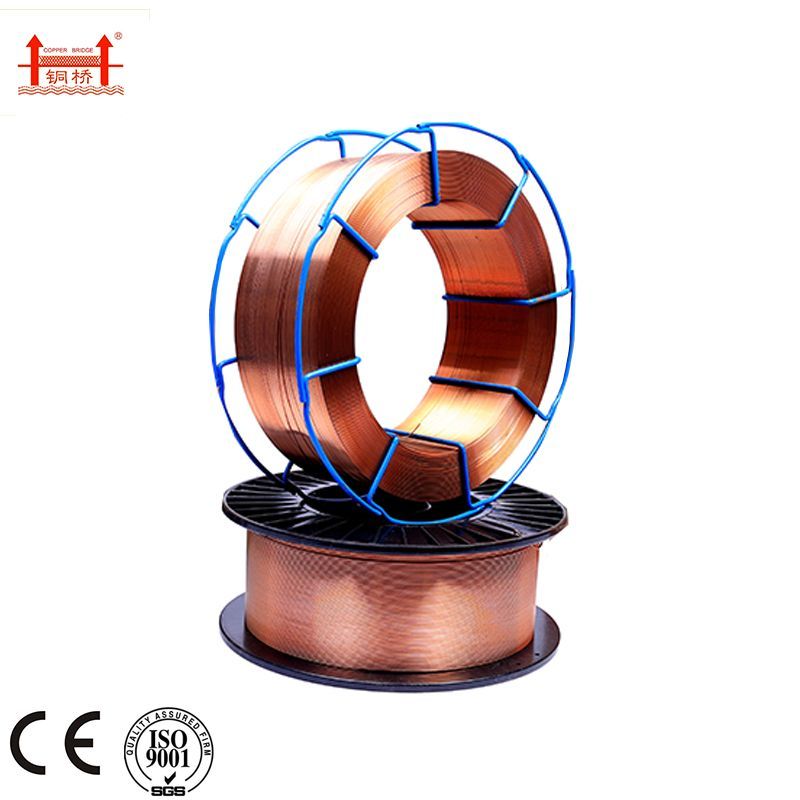

Argon Arc Welding Wire Overview

In professional fabrication, Argon Arc Welding Wire is engineered for gas-shielded processes where argon delivers a stable, inert envelope around the arc and molten pool. For aluminum structures, the go-to specification is ER5356 (aluminum-magnesium), valued for strength, corrosion resistance, and excellent bead appearance. Why is argon used in arc welding? Because argon’s inert nature prevents oxidation, stabilizes the arc, and produces clean, low-spatter welds—vital when joining aluminum in marine, transportation, pressure vessel, and architectural applications.

- Technical profile: ER5356 typically contains ~5% Mg for strength and crack resistance, supports AC TIG and MIG with argon or argon-rich mixes, and is offered in common diameters (e.g., 0.8–1.6 mm) and multiple spool sizes to fit semi-automatic or robotic cells.

- Process context: In arc and MIG welding difference discussions, “arc” often refers to SMAW (stick), while argon-based MIG/TIG (GMAW/GTAW) provides superior control on aluminum. That’s the core of arc welding vs argon welding debates—argon-shielded processes win on cleanliness and precision.

- Manufacturing credibility: Dingzhou Jinlong Metal Production Co., Ltd. supplies consistent, tightly toleranced wire that feeds smoothly and supports repeatable parameters—critical for B2B operations demanding throughput and first-pass quality.

Benefits & Use Cases of Argon Arc Welding Wire in Argon arc welding wire

From boat hulls and truck bodies to heat exchangers and handrails, ER5356 Argon Arc Welding Wire is the industry’s workhorse for high-strength, corrosion-resistant aluminum joints. In mig welding vs arc welding comparisons, MIG (with argon or Ar/He) provides higher deposition and productivity than SMAW, while TIG offers unmatched cosmetic quality. In other words, arc MIG and TIG welding each have a place: for “arc or MIG what is better,” the right answer depends on required appearance, speed, and joint access.

- Applications: Marine fabrications (saltwater resistance), vehicle frames, fuel tanks, piping, and structural extrusions where clean, ductile, and strong welds are non-negotiable.

- Advantages: Stable arc starts, low spatter, excellent wetting, and bright, uniform beads reduce rework. Compared to CO2 welding vs arc welding on aluminum, argon shielding is essential—CO2 is reactive and unsuitable for most aluminum jobs.

- Process clarity: Difference between TIG welding and arc welding (SMAW) is control and cleanliness—TIG with argon is precise and ideal for thin sections; SMAW is more forgiving outdoors but impractical on aluminum. Dingzhou Jinlong Metal Production Co., Ltd. optimizes wire cast/helix, surface finish, and winding for reliable feeding in both semi-automatic and robotic MIG cells, and superior puddle control in TIG.

Cost, Maintenance & User Experience

Total cost of ownership for Argon Arc Welding Wire is driven by deposition efficiency, wire feeding stability, and post-weld cleanup. With high-quality ER5356, smoother feeding reduces burnbacks and downtime; cleaner beads mean less grinding and repainting; and consistent chemistry cuts defect rates. The ROI shows up in fewer touch-ups per meter of weld, higher travel speeds in MIG, and consistent parameter windows that shorten operator training time.

- Maintenance: Store wire in dry, clean environments; keep liners, contact tips, and drive rolls matched to wire diameter; and verify gas purity. These practices preserve arc stability and minimize porosity.

- User feedback: Fabricators in the Welding supplies sector report steady arc starts, consistent bead profile, and lower rework when switching to Dingzhou Jinlong Metal Production Co., Ltd. ER5356. In MIG-heavy production, customers cite throughput gains alongside a measurable drop in spatter-related cleanup—key contributors to an attractive payback period.

Sustainability & Market Trends in industrial supplies

Industrial buyers increasingly evaluate welding consumables through an ESG lens. Argon-shielded MIG/TIG on aluminum generates clean, low-spatter welds that reduce secondary finishing, energy use, and waste. With stricter regulations and tighter quality systems, shops are standardizing on stable formulations like ER5356 to support automation and in-line inspection. Meanwhile, the ongoing “arc welding vs argon welding” conversation favors argon-shielded processes for aluminum because they improve joint integrity and repeatability—critical for robotics and ISO-compliant operations.

- Regulatory alignment: Cleaner welds reduce airborne particulates and abrasive cleanup residues, supporting safer workplaces and environmental targets.

- Forward-thinking supply: Dingzhou Jinlong Metal Production Co., Ltd. prioritizes consistent metallurgy, precision drawing, and efficient packaging that minimizes scrap and protects wire surfaces—an eco-conscious approach that also enhances feeding in automated cells.

Conclusion on Argon Arc Welding Wire from Dingzhou Jinlong Metal Production Co., Ltd.

For B2B decision makers, Argon Arc Welding Wire—especially ER5356 for aluminum—delivers the productivity, consistency, and finish quality required in modern fabrication. Whether you’re evaluating mig welding vs arc welding, or clarifying the difference between TIG welding and arc welding, argon-shielded processes paired with the right wire win on cleanliness, control, and throughput. Dingzhou Jinlong Metal Production Co., Ltd. is trusted for durable, high-performance consumables that keep lines running and quality high.

- Contact us: email: CJL751229@jinlongmetals.com

- Visit our website: https://www.jinlongweldingelectrode.com

Related Video