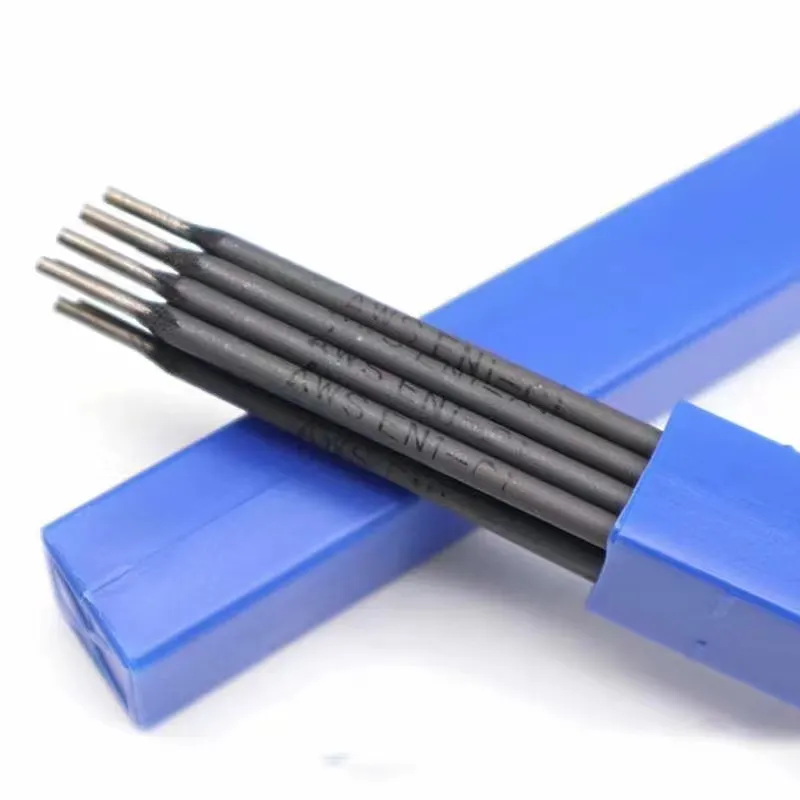

aws 7018 welding rod

Februari . 11, 2025 01:56

Selecting the right welding rod for a project plays a crucial role in determining the final quality and integrity of the weld. The 5 32 welding rod 7018 stands out as an exceptional choice for professionals seeking a balance between ease of use and superior results. For those venturing into the realm of arc welding, understanding the merits and nuances of the 7018 electrode is essential.

For welders accustomed to the nuances of different rods, the 7018 offers a smooth, stable arc and a clean, presentable weld. Its slag is easily removable, and the resultant weld has an aesthetically pleasing appearance, typically requiring minimal finishing work. This attribute is particularly beneficial in projects where the visual presentation of the weld is just as important as its strength, such as in ornamental ironwork or visible steel structures. While the 7018 is largely celebrated, successful use requires skill and understanding of its unique characteristics. Novices might find this rod slightly challenging due to its specific heat requirements and the importance of maintaining the correct arc length. However, with practice and a little guidance from seasoned professionals, most welders can harness the full potential of the 7018, producing superior quality welds that stand the test of time. Beyond the technical aspects, the 5/32 7018 rod embodies the spirit of what it means to be a welder a pursuit of excellence, precision, and attention to detail. Investing time in understanding this tool is investing in one’s craft. Professional development workshops and certification programs often emphasize the effective use of 7018 rods, underscoring their significance in the welding arsenal. In conclusion, the 5/32 7018 welding rod is more than just an option; it is a cornerstone in the world of welding, representing strength, reliability, and versatility. As technology evolves and industry demands grow, the foundational importance of such tools remains constant, reminding welders of the essential balance between innovation and time-tested techniques. Whether a project demands resilience under stress or immaculate weld lines, the 7018 is equipped to meet and exceed expectations, reassuring both welders and their clients of a job well executed.

For welders accustomed to the nuances of different rods, the 7018 offers a smooth, stable arc and a clean, presentable weld. Its slag is easily removable, and the resultant weld has an aesthetically pleasing appearance, typically requiring minimal finishing work. This attribute is particularly beneficial in projects where the visual presentation of the weld is just as important as its strength, such as in ornamental ironwork or visible steel structures. While the 7018 is largely celebrated, successful use requires skill and understanding of its unique characteristics. Novices might find this rod slightly challenging due to its specific heat requirements and the importance of maintaining the correct arc length. However, with practice and a little guidance from seasoned professionals, most welders can harness the full potential of the 7018, producing superior quality welds that stand the test of time. Beyond the technical aspects, the 5/32 7018 rod embodies the spirit of what it means to be a welder a pursuit of excellence, precision, and attention to detail. Investing time in understanding this tool is investing in one’s craft. Professional development workshops and certification programs often emphasize the effective use of 7018 rods, underscoring their significance in the welding arsenal. In conclusion, the 5/32 7018 welding rod is more than just an option; it is a cornerstone in the world of welding, representing strength, reliability, and versatility. As technology evolves and industry demands grow, the foundational importance of such tools remains constant, reminding welders of the essential balance between innovation and time-tested techniques. Whether a project demands resilience under stress or immaculate weld lines, the 7018 is equipped to meet and exceed expectations, reassuring both welders and their clients of a job well executed.

Related Video

Copyright © 2025 Dingzhou Jinlong Metal Production Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy