ss steel welding rod

Фев . 14, 2025 07:31

Stainless steel welding rods are indispensable tools in the world of professional metalwork, known for their versatility and capability to produce strong, durable joints. The unique composition of stainless steel requires a thorough understanding and exhaustive expertise to meet the demands of professionals who seek enhanced performance and reliability. For anyone engaged in metal fabrication, construction, or repair, understanding stainless steel welding rods is crucial to achieving professional-grade results.

Trustworthiness in the realm of stainless steel welding rod application is built upon a foundation of proven results and reliable performance. Experienced welders rely on these tools for their consistent results, minimizing defects and ensuring the structural integrity of the finished product. As welders create precision joints in pressure pipes, food processing equipment, and commercial kitchen installations, the dependability of the weld is never questioned. Using stainless steel welding rods efficiently manifests a clear understanding of metallurgy combined with hands-on application skills. For example, controlling heat input is vital; excess heat can lead to warping or weaken the joint, whereas insufficient heat may result in incomplete fusion. A steady hand paired with the correct settings on the welding equipment will yield the best results. Advanced skills, such as pulsed arc welding, are sometimes employed to better manage heat input, especially in thin-gauge materials. Enhancing the quality of the finished weld involves additional practices such as back purging and employing flux-coated rods to protect the weld from atmospheric contamination. The result is a smoothly executed, visually appealing joint free of cracks and imperfections — a mark of true craftsmanship in metal fabrication. Furthermore, continuous training and certification are important for those who wish to maintain their expertise in welding stainless steel. Certifications such as those provided by the American Welding Society (AWS) assure employers and clients of the welder's competence and understanding of industry standards. Investing in such credentials fortifies one's trustworthiness and authority in delivering top-tier welding services. In summary, the multifaceted nature of stainless steel welding rods demands an amalgamation of experience, professional expertise, authoritative product knowledge, and an unwavering commitment to trustworthiness in application. Mastery over these elements propels professionals to the forefront of the metal fabrication arena, ensuring they deliver not only strong and resilient welds but also foster innovation and quality across industries that value the sanctity of form and function.

Trustworthiness in the realm of stainless steel welding rod application is built upon a foundation of proven results and reliable performance. Experienced welders rely on these tools for their consistent results, minimizing defects and ensuring the structural integrity of the finished product. As welders create precision joints in pressure pipes, food processing equipment, and commercial kitchen installations, the dependability of the weld is never questioned. Using stainless steel welding rods efficiently manifests a clear understanding of metallurgy combined with hands-on application skills. For example, controlling heat input is vital; excess heat can lead to warping or weaken the joint, whereas insufficient heat may result in incomplete fusion. A steady hand paired with the correct settings on the welding equipment will yield the best results. Advanced skills, such as pulsed arc welding, are sometimes employed to better manage heat input, especially in thin-gauge materials. Enhancing the quality of the finished weld involves additional practices such as back purging and employing flux-coated rods to protect the weld from atmospheric contamination. The result is a smoothly executed, visually appealing joint free of cracks and imperfections — a mark of true craftsmanship in metal fabrication. Furthermore, continuous training and certification are important for those who wish to maintain their expertise in welding stainless steel. Certifications such as those provided by the American Welding Society (AWS) assure employers and clients of the welder's competence and understanding of industry standards. Investing in such credentials fortifies one's trustworthiness and authority in delivering top-tier welding services. In summary, the multifaceted nature of stainless steel welding rods demands an amalgamation of experience, professional expertise, authoritative product knowledge, and an unwavering commitment to trustworthiness in application. Mastery over these elements propels professionals to the forefront of the metal fabrication arena, ensuring they deliver not only strong and resilient welds but also foster innovation and quality across industries that value the sanctity of form and function.

Related Video

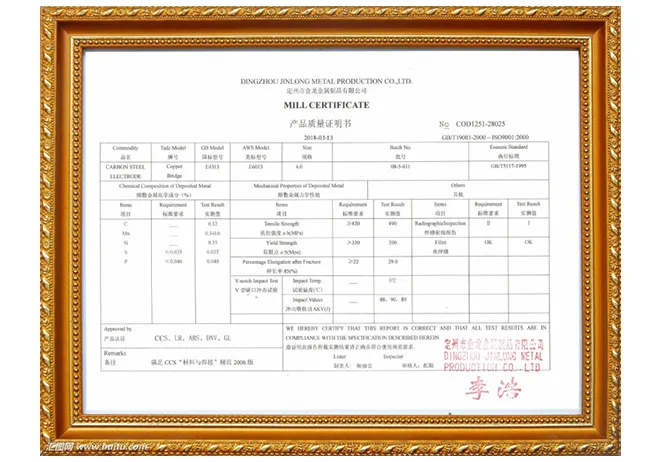

Copyright © 2025 Dingzhou Jinlong Metal Production Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy