AWS EZ308 Cast Iron Welding Rods 2.0mm-5.0mm

ਫਰ. . 10, 2025 22:13

When selecting the appropriate welding rod for 1/8-inch steel, there are several vital considerations to keep in mind that can make a significant difference in the quality of your welds. Welding 1/8-inch steel, often used for automotive repairs, home projects, and small-scale construction, demands attention to detail and the right materials to achieve a seamless, durable connection. Here's a deep dive into the experience, expertise, authoritativeness, and trustworthiness required to make an informed choice.

Real-life experience plays an indispensable role. Seasoned welders often test various rods to determine what provides the best performance in terms of penetration and ease of use on 1/8-inch steel. Personal trials and practice enable welders to fine-tune their technique, balancing travel speed, angle, and current to achieve optimal outcomes. Engaging with professional communities, online forums, or workshops can further enhance understanding and technique refinement by learning from the shared experiences of others in the field. Additionally, the cleanliness of the base material is essential. New or less experienced welders might overlook this aspect, which can result in welds with poor fusion and trapped slag. Ensuring that the 1/8-inch steel is free of rust, paint, or contaminants before welding is a step that cannot be skipped, as it significantly influences strength and appearance. Finally, trustworthiness in the welding industry is enhanced through continuous education and staying updated with the latest welding techniques and technology. Enrolling in courses or certifications provided by institutions like the American Welding Society (AWS) can augment a professional's credentials and ensure they remain informed about the latest best practices. In summary, selecting a welding rod for 1/8-inch steel is not a one-size-fits-all task. It demands a blend of expertise, hands-on experience, and reliable products. By considering advice from authoritative sources, practicing regularly, and choosing high-quality materials, welders can ensure that they achieve clean, strong welds consistently. This comprehensive approach not only uplifts the quality of work but also fortifies trust with clients or end-users, confirming the value of skilled craftsmanship in the welding profession.

Real-life experience plays an indispensable role. Seasoned welders often test various rods to determine what provides the best performance in terms of penetration and ease of use on 1/8-inch steel. Personal trials and practice enable welders to fine-tune their technique, balancing travel speed, angle, and current to achieve optimal outcomes. Engaging with professional communities, online forums, or workshops can further enhance understanding and technique refinement by learning from the shared experiences of others in the field. Additionally, the cleanliness of the base material is essential. New or less experienced welders might overlook this aspect, which can result in welds with poor fusion and trapped slag. Ensuring that the 1/8-inch steel is free of rust, paint, or contaminants before welding is a step that cannot be skipped, as it significantly influences strength and appearance. Finally, trustworthiness in the welding industry is enhanced through continuous education and staying updated with the latest welding techniques and technology. Enrolling in courses or certifications provided by institutions like the American Welding Society (AWS) can augment a professional's credentials and ensure they remain informed about the latest best practices. In summary, selecting a welding rod for 1/8-inch steel is not a one-size-fits-all task. It demands a blend of expertise, hands-on experience, and reliable products. By considering advice from authoritative sources, practicing regularly, and choosing high-quality materials, welders can ensure that they achieve clean, strong welds consistently. This comprehensive approach not only uplifts the quality of work but also fortifies trust with clients or end-users, confirming the value of skilled craftsmanship in the welding profession.

Related Video

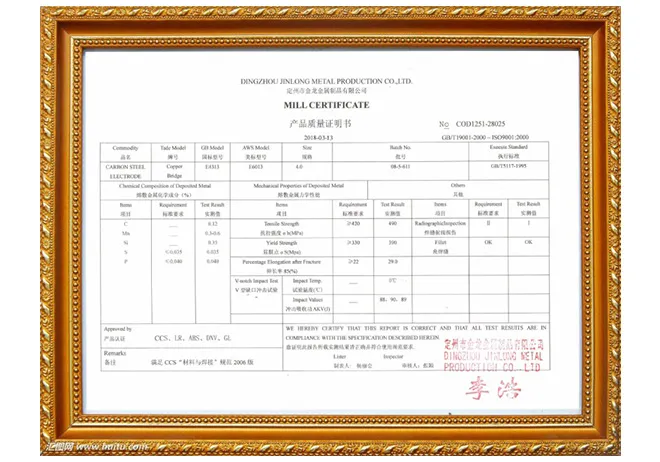

Copyright © 2025 Dingzhou Jinlong Metal Production Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy