welding rod 6013 3.2 mm

Jan . 20, 2025 08:42

Selecting the right welding rod is crucial for ensuring a strong and durable weld, particularly when working with different types of metals and welding techniques. Among the various options, the 6013 3.2 mm welding rod stands out due to its versatile applications and favorable characteristics that cater to both amateur welders and seasoned professionals.

Field experts often emphasize the importance of electrode selection based on the specific characteristics of the workpiece material. The 6013 rod is well suited for non-critical applications using mild steels, hence its widespread use in automotive repairs, ornamental iron work, and maintenance operations. Despite the availability of advanced welding technologies, the reliability and versatility of the 6013 continue to hold strong in its niche applications. In settings where consistent production is essential, welders often rely on the predictability that the 6013 provides. This consistency not only helps professionals meet deadlines but also ensures that the weld quality remains uncompromised, thereby enhancing trust with clientele who expect dependable results. Furthermore, many seasoned welders acknowledge the importance of practice and technical competence, specifically with the 6013 electrode. Mastery of welding techniques such as travel speed and angle of approach can significantly affect the outcome, highlighting the need for ongoing skills development even with user-friendly electrodes like the 6013. As with any welding undertaking, safety remains a pivotal aspect of using the 6013 3.2 mm welding rod. Ensuring proper ventilation, personal protective equipment, and adherence to safety guidelines cannot be overstated. These precautions not only safeguard the welder but also contribute to the overall efficiency and quality of the welding process. In summary, the 6013 3.2 mm welding rod is a robust tool in the welders' arsenal, offering convenience, reliability, and adaptable performance across various metalworking projects. Its established trustworthiness and expert endorsement make it a favored choice, ensuring both novice and experienced welders achieve high-quality results tailored to their specific needs. Selecting the 6013 rod effectively entails understanding its strengths and optimizing its application to align with project requirements, ultimately resulting in superior workmanship and enhanced professional credibility.

Field experts often emphasize the importance of electrode selection based on the specific characteristics of the workpiece material. The 6013 rod is well suited for non-critical applications using mild steels, hence its widespread use in automotive repairs, ornamental iron work, and maintenance operations. Despite the availability of advanced welding technologies, the reliability and versatility of the 6013 continue to hold strong in its niche applications. In settings where consistent production is essential, welders often rely on the predictability that the 6013 provides. This consistency not only helps professionals meet deadlines but also ensures that the weld quality remains uncompromised, thereby enhancing trust with clientele who expect dependable results. Furthermore, many seasoned welders acknowledge the importance of practice and technical competence, specifically with the 6013 electrode. Mastery of welding techniques such as travel speed and angle of approach can significantly affect the outcome, highlighting the need for ongoing skills development even with user-friendly electrodes like the 6013. As with any welding undertaking, safety remains a pivotal aspect of using the 6013 3.2 mm welding rod. Ensuring proper ventilation, personal protective equipment, and adherence to safety guidelines cannot be overstated. These precautions not only safeguard the welder but also contribute to the overall efficiency and quality of the welding process. In summary, the 6013 3.2 mm welding rod is a robust tool in the welders' arsenal, offering convenience, reliability, and adaptable performance across various metalworking projects. Its established trustworthiness and expert endorsement make it a favored choice, ensuring both novice and experienced welders achieve high-quality results tailored to their specific needs. Selecting the 6013 rod effectively entails understanding its strengths and optimizing its application to align with project requirements, ultimately resulting in superior workmanship and enhanced professional credibility.

Related Video

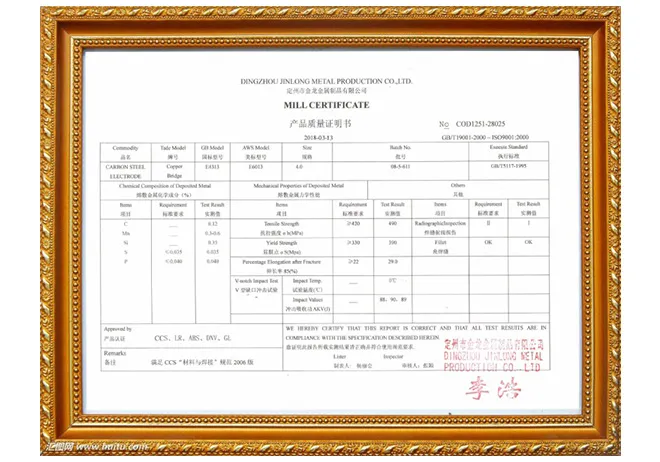

Copyright © 2025 Dingzhou Jinlong Metal Production Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy