ss welding rod code

Feb . 16, 2025 15:11

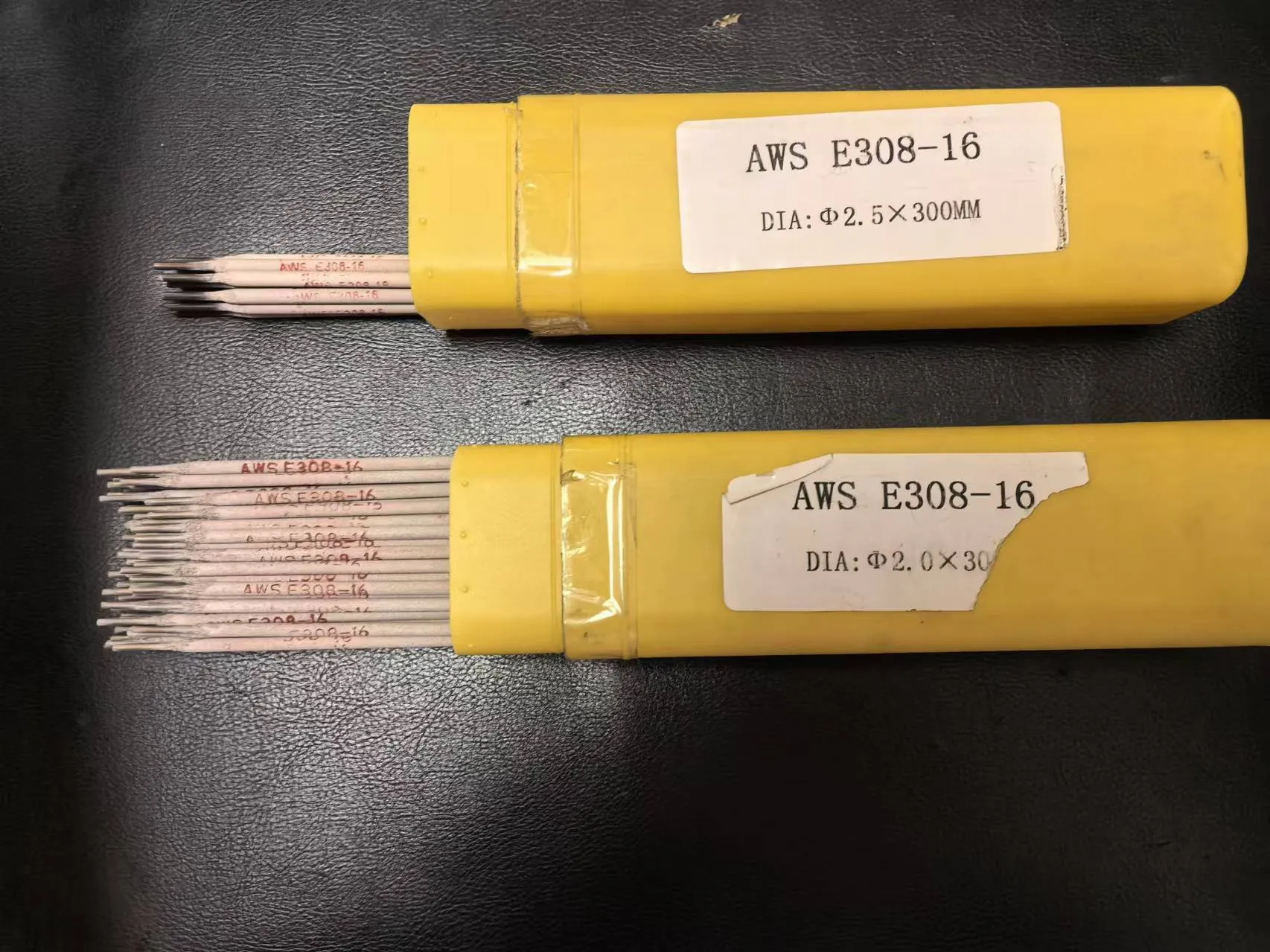

When it comes to selecting the ideal welding rod, understanding the specific code associated with SS (stainless steel) welding rods is crucial for both novice and experienced welders. With the right rod, you ensure a strong weld, maintain the integrity of your project, and minimize potential issues. Here's an insightful breakdown of the SS welding rod code that can enhance your welding experience.

Another crucial aspect that demonstrates authority in choosing the right SS welding rod is comprehending the welder’s positioning capabilities as indicated in the code. Some rods are designed for ease of use in specific positions, such as flat or horizontal welding, which can impact the choice based on the project requirements and the welder’s proficiency. For products used in critical structural applications, adhering to recognized standards such as AWS (American Welding Society) provides an additional layer of credibility. AWSS welding rod codes reflect stringent quality standards, ensuring the rods have undergone rigorous testing to meet safety and performance criteria. Maintaining welding equipment and ensuring correct settings is another dimension of welding expertise. The application of the appropriate voltage, current, and speed, adjusted according to the SS welding rod’s specifications, directly affects the weld quality. Such parameters are often indicated alongside the rod code, guiding welders in achieving precision. Experience with SS welding rods also embodies practical knowledge regarding storage and handling. Proper storage to prevent moisture absorption is essential, as moisture can cause hydrogen-induced cracking in the weld. Using air-tight containers or sealed packaging is a standard practice recommended to preserve rod quality and effectiveness. Lastly, community engagement and continuous learning, through forums and workshops, bolster a welder's proficiency in using SS welding rods effectively. Sharing insights and solutions on industry platforms adds credibility to one’s practice and keeps professionals updated with evolving technologies and techniques in metalwork. In conclusion, understanding SS welding rod codes is more than just a technical requirement; it is a foundational element that enhances welding quality, safety, and efficiency. Welders equipped with this knowledge can confidently manage projects that demand the highest standards of performance and reliability, ultimately fostering trust and authority in their craftsmanship.

Another crucial aspect that demonstrates authority in choosing the right SS welding rod is comprehending the welder’s positioning capabilities as indicated in the code. Some rods are designed for ease of use in specific positions, such as flat or horizontal welding, which can impact the choice based on the project requirements and the welder’s proficiency. For products used in critical structural applications, adhering to recognized standards such as AWS (American Welding Society) provides an additional layer of credibility. AWSS welding rod codes reflect stringent quality standards, ensuring the rods have undergone rigorous testing to meet safety and performance criteria. Maintaining welding equipment and ensuring correct settings is another dimension of welding expertise. The application of the appropriate voltage, current, and speed, adjusted according to the SS welding rod’s specifications, directly affects the weld quality. Such parameters are often indicated alongside the rod code, guiding welders in achieving precision. Experience with SS welding rods also embodies practical knowledge regarding storage and handling. Proper storage to prevent moisture absorption is essential, as moisture can cause hydrogen-induced cracking in the weld. Using air-tight containers or sealed packaging is a standard practice recommended to preserve rod quality and effectiveness. Lastly, community engagement and continuous learning, through forums and workshops, bolster a welder's proficiency in using SS welding rods effectively. Sharing insights and solutions on industry platforms adds credibility to one’s practice and keeps professionals updated with evolving technologies and techniques in metalwork. In conclusion, understanding SS welding rod codes is more than just a technical requirement; it is a foundational element that enhances welding quality, safety, and efficiency. Welders equipped with this knowledge can confidently manage projects that demand the highest standards of performance and reliability, ultimately fostering trust and authority in their craftsmanship.

Related Video

Copyright © 2025 Dingzhou Jinlong Metal Production Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy