arc welding vs argon welding

Feb . 14, 2025 04:54

Selecting the right welding electrode is crucial for achieving a stable and high-quality weld, particularly when using shielded metal arc welding (SMAW) techniques. SS arc welding electrodes are pivotal in this regard due to their unique properties that cater to specific needs across diverse industry applications.

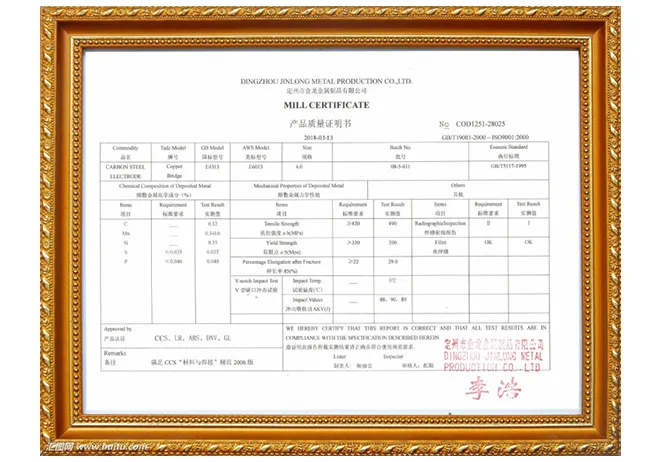

For welders, the choice of electrode often influences the welding technique and parameters. With SS arc welding electrodes, it is imperative to maintain a consistent arc length and angle. A deeper focus on maintaining a steady hand and learning the rhythm of electrode consumption can make a noticeable difference in weld quality and efficiency. The electrode’s diameter should also be chosen in concordance with the welding position and thickness of the material to ensure optimal penetration and fusion. The authoritativeness of SS arc welding electrode manufacturers can often be assessed by their adherence to international standards and certifications. Products from manufacturers that comply with stringent guidelines such as those outlined in the American Welding Society (AWS) standards are generally more reliable. Professionals and businesses are advised to verify these credentials and the manufacturer’s track record for supplying consistent, high-quality electrodes. Trustworthiness in the domain of welding also extends to the availability and reliability of customer support from electrode suppliers. Reputable suppliers not only offer premium products but also provide guidance and post-sale service that can assist in troubleshooting and optimizing welding processes. Such support can prove invaluable in enhancing operational efficiency and achieving the desired weld outcomes. In conclusion, the selection and use of SS arc welding electrodes are an intricate game of aligning environmental, technical, and operational factors. The profound understanding of how these electrodes interact with different materials, and the adherence to industry standards, are critical in delivering superior, reliable welds. For those in the welding industry, investing in high-quality SS electrodes and leveraging their full potential through expert guidance can translate into significant long-term benefits, marked by enhanced weld integrity and reduced operational inefficiencies.

For welders, the choice of electrode often influences the welding technique and parameters. With SS arc welding electrodes, it is imperative to maintain a consistent arc length and angle. A deeper focus on maintaining a steady hand and learning the rhythm of electrode consumption can make a noticeable difference in weld quality and efficiency. The electrode’s diameter should also be chosen in concordance with the welding position and thickness of the material to ensure optimal penetration and fusion. The authoritativeness of SS arc welding electrode manufacturers can often be assessed by their adherence to international standards and certifications. Products from manufacturers that comply with stringent guidelines such as those outlined in the American Welding Society (AWS) standards are generally more reliable. Professionals and businesses are advised to verify these credentials and the manufacturer’s track record for supplying consistent, high-quality electrodes. Trustworthiness in the domain of welding also extends to the availability and reliability of customer support from electrode suppliers. Reputable suppliers not only offer premium products but also provide guidance and post-sale service that can assist in troubleshooting and optimizing welding processes. Such support can prove invaluable in enhancing operational efficiency and achieving the desired weld outcomes. In conclusion, the selection and use of SS arc welding electrodes are an intricate game of aligning environmental, technical, and operational factors. The profound understanding of how these electrodes interact with different materials, and the adherence to industry standards, are critical in delivering superior, reliable welds. For those in the welding industry, investing in high-quality SS electrodes and leveraging their full potential through expert guidance can translate into significant long-term benefits, marked by enhanced weld integrity and reduced operational inefficiencies.

Related Video

Copyright © 2025 Dingzhou Jinlong Metal Production Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy