cast iron electrode

Mar . 04, 2025 07:47

Welding electrodes play an essential role in the metal fabrication industry, especially when dealing with the challenging task of welding cast iron. Cast iron is a ferrous alloy consisting of iron, carbon, and silicon, known for its brittleness and high carbon content. Proper electrode selection is crucial to achieve strong and durable welds on cast iron pieces. When it comes to milliseconds to cast iron welding electrode numbers, understanding the essential characteristics of these electrodes is key to success.

Real-world experience emphasizes the importance of pre-heating the cast iron workpiece before welding. Pre-heating to temperatures between 250°F to 500°F can significantly reduce the risk of thermal shock, which causes cracking. Additionally, post-weld heat treatment can be vital in relieving welding-induced stresses. Numbers and procedures for these practices vary depending on the specific nature of the cast iron alloy and the electrode used, making consulting technical datasheets and expert opinions indispensable. The diverse nature of cast iron alloys necessitates a thorough understanding of the material's properties and the operating environment of the weld. Consulting with seasoned welding professionals and relying on trusted suppliers for welding electrodes can greatly enhance the reliability and performance of the welds. Workshops and training offered by welding supply firms or industry associations are valuable resources for acquiring a deeper understanding of electrode applications and achieving optimal results. Understanding the environment and conditions under which the cast iron component will function post-weld can dictate the choice of electrode. For example, if the welded part will undergo repetitive stress, high-resistance nickel-based electrodes might be preferred over more brittle options. Conversely, in less demanding scenarios, cost-effective steel electrodes may suffice. Effective selection and application of the right cast iron welding electrode extend beyond just the numerical identification of the product. It involves an amalgamation of expert insights, pre- and post-welding techniques, and an appreciation for the unique challenges posed by cast iron materials. While navigating this complex terrain, prioritizing expertise, authoritativeness, and trustworthiness ensures a solid foundation for successful welding outcomes, making it imperative to continually update one’s knowledge base and adapt to emerging trends and technologies in the welding field.

Real-world experience emphasizes the importance of pre-heating the cast iron workpiece before welding. Pre-heating to temperatures between 250°F to 500°F can significantly reduce the risk of thermal shock, which causes cracking. Additionally, post-weld heat treatment can be vital in relieving welding-induced stresses. Numbers and procedures for these practices vary depending on the specific nature of the cast iron alloy and the electrode used, making consulting technical datasheets and expert opinions indispensable. The diverse nature of cast iron alloys necessitates a thorough understanding of the material's properties and the operating environment of the weld. Consulting with seasoned welding professionals and relying on trusted suppliers for welding electrodes can greatly enhance the reliability and performance of the welds. Workshops and training offered by welding supply firms or industry associations are valuable resources for acquiring a deeper understanding of electrode applications and achieving optimal results. Understanding the environment and conditions under which the cast iron component will function post-weld can dictate the choice of electrode. For example, if the welded part will undergo repetitive stress, high-resistance nickel-based electrodes might be preferred over more brittle options. Conversely, in less demanding scenarios, cost-effective steel electrodes may suffice. Effective selection and application of the right cast iron welding electrode extend beyond just the numerical identification of the product. It involves an amalgamation of expert insights, pre- and post-welding techniques, and an appreciation for the unique challenges posed by cast iron materials. While navigating this complex terrain, prioritizing expertise, authoritativeness, and trustworthiness ensures a solid foundation for successful welding outcomes, making it imperative to continually update one’s knowledge base and adapt to emerging trends and technologies in the welding field.

Related Video

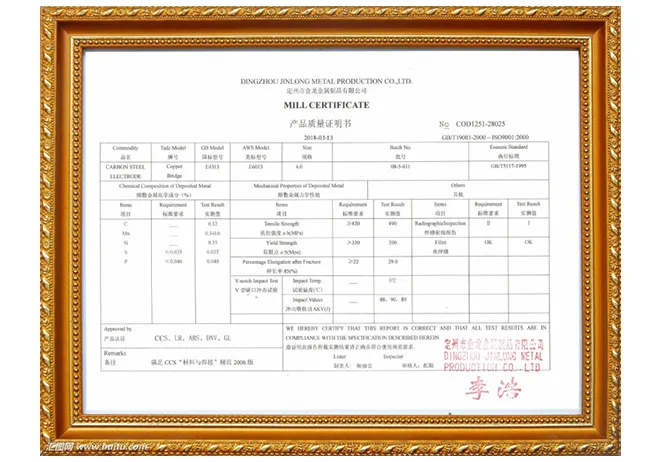

Copyright © 2025 Dingzhou Jinlong Metal Production Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy