cast iron tig welding rod

Feb . 15, 2025 04:58

Low temperature welding rods for stainless steel represent a pivotal advancement in the welding industry, catering to both seasoned professionals and hobbyists. These rods function under the principle of welding at temperatures significantly lower than traditional methods, transforming how stainless steel projects are executed.

ASE-certified technicians, seasoned creators, or anyone with an affinity for constructing with metal can attest to the trustworthiness of these rods. In addition, the packaging often includes detailed instructional guides and safety manuals, emphasizing user-friendly guidance and best practices. The acknowledgment from industry professionals further ensconces low temperature welding rods as a trusted tool in metalworking. Experience speaks volumes when one embraces the clean finish that low temperature welding affords. Imagine completing a piece without the typical warping or discoloration that commonly mars the final result in stainless steel work. It redefines quality control and client satisfaction, especially in sectors where every detail matters. Utilizing low temperature welding rods for stainless steel also caters to environmental conscientiousness. Reduced energy consumption aligns with eco-friendly initiatives, further marking these rods as a forward-thinking solution in the welding landscape. By lowering the operational temperature, energy expenditure decreases, making it a sustainable choice amidst growing environmental concerns. As the technology behind these rods gains more traction, the expertise they bring to the table cannot be overstated. Workshops and professional settings that embrace this technology often report enhanced productivity and the strategic advantage of producing flawless stainless steel projects efficiently. The acknowledgment from the community, coupled with ongoing advancements in their formula, solidifies their position as an authoritative figure in the welding sector. In conclusion, low temperature welding rods are more than just an innovative product—they represent a shift towards safer, versatile, and more responsible welding practices. The seamless integration of these rods into your toolkit can enhance craftsmanship and significantly improve the end result of your projects. As you explore the possibilities they unlock, you'll find yourself leading the charge in modern stainless steel construction and design, empowered by the reliable and expert-backed capabilities of low temperature welding rods.

ASE-certified technicians, seasoned creators, or anyone with an affinity for constructing with metal can attest to the trustworthiness of these rods. In addition, the packaging often includes detailed instructional guides and safety manuals, emphasizing user-friendly guidance and best practices. The acknowledgment from industry professionals further ensconces low temperature welding rods as a trusted tool in metalworking. Experience speaks volumes when one embraces the clean finish that low temperature welding affords. Imagine completing a piece without the typical warping or discoloration that commonly mars the final result in stainless steel work. It redefines quality control and client satisfaction, especially in sectors where every detail matters. Utilizing low temperature welding rods for stainless steel also caters to environmental conscientiousness. Reduced energy consumption aligns with eco-friendly initiatives, further marking these rods as a forward-thinking solution in the welding landscape. By lowering the operational temperature, energy expenditure decreases, making it a sustainable choice amidst growing environmental concerns. As the technology behind these rods gains more traction, the expertise they bring to the table cannot be overstated. Workshops and professional settings that embrace this technology often report enhanced productivity and the strategic advantage of producing flawless stainless steel projects efficiently. The acknowledgment from the community, coupled with ongoing advancements in their formula, solidifies their position as an authoritative figure in the welding sector. In conclusion, low temperature welding rods are more than just an innovative product—they represent a shift towards safer, versatile, and more responsible welding practices. The seamless integration of these rods into your toolkit can enhance craftsmanship and significantly improve the end result of your projects. As you explore the possibilities they unlock, you'll find yourself leading the charge in modern stainless steel construction and design, empowered by the reliable and expert-backed capabilities of low temperature welding rods.

Related Video

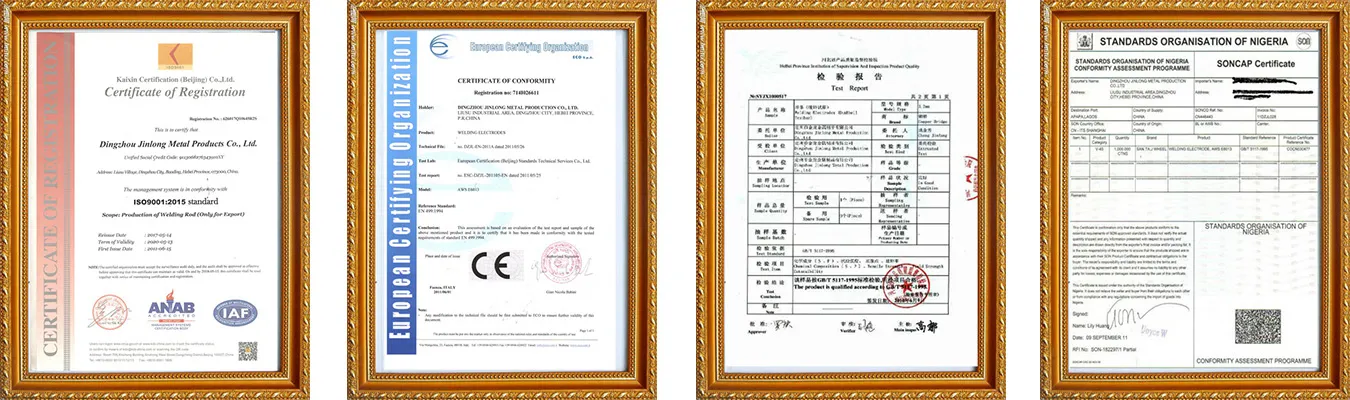

Copyright © 2025 Dingzhou Jinlong Metal Production Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy