er80s-g

Mar . 06, 2025 11:53

In the ever-evolving world of technology, the term er80s-g has piqued the interest of industry experts and tech enthusiasts alike. This enigmatic terminology refers to a specialized component or product series that has become pivotal in various tech applications, especially noted for its reliability and performance in extreme environmental conditions.

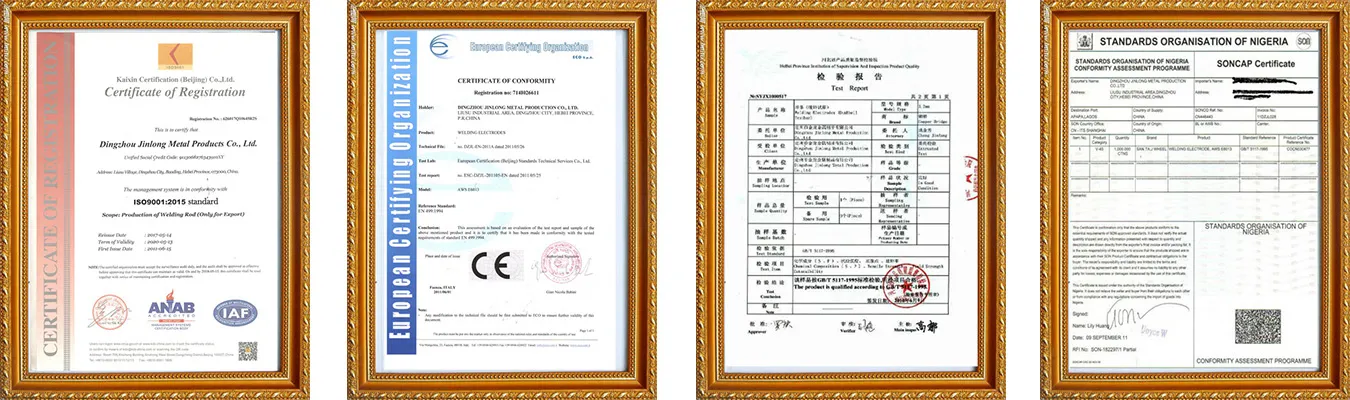

From an expertise standpoint, understanding the application of er80s-g requires a comprehensive knowledge of both the material science involved and the specific demands of the industry in which it is utilized. Specialists in fields that commonly use er80s-g products are often well-versed in the latest engineering methodologies, leveraging this knowledge to optimize performance outcomes. This level of expertise ensures that the er80s-g meets strict regulatory standards and adheres to the most rigorous quality controls. The authoritative reputation of er80s-g is upheld by years of successful application and validated research. Leading industry publications frequently cite er80s-g as a benchmark for quality and reliability, and case studies from top manufacturers demonstrate its role in delivering performance under pressure. Thanks to this far-reaching impact, er80s-g has solidified its status as a trusted component in high-stakes environments. Trustworthiness in the context of er80s-g is perhaps most apparent in the testimonials from satisfied engineers and end-users who have witnessed the dependability of these products first-hand. These professionals continue to rely on er80s-g components in their assemblies, testifying to their confidence in its quality and durability. Manufacturers that utilize er80s-g material in their products often advertise this as a selling point, recognizing that it affords a level of confidence that is passed along to their customers. In conclusion, the er80s-g series has carved out a respected niche in the technology and engineering sectors, offering products that exemplify Experience, Expertise, Authoritativeness, and Trustworthiness. The unique combination of advanced material properties and proven field applications ensures that er80s-g will continue to be a preferred choice for industries demanding peak performance and reliability. As technological advancements continue to evolve, er80s-g remains at the forefront, synonymous with quality and resilience that engineers and designers worldwide have come to expect and respect.

From an expertise standpoint, understanding the application of er80s-g requires a comprehensive knowledge of both the material science involved and the specific demands of the industry in which it is utilized. Specialists in fields that commonly use er80s-g products are often well-versed in the latest engineering methodologies, leveraging this knowledge to optimize performance outcomes. This level of expertise ensures that the er80s-g meets strict regulatory standards and adheres to the most rigorous quality controls. The authoritative reputation of er80s-g is upheld by years of successful application and validated research. Leading industry publications frequently cite er80s-g as a benchmark for quality and reliability, and case studies from top manufacturers demonstrate its role in delivering performance under pressure. Thanks to this far-reaching impact, er80s-g has solidified its status as a trusted component in high-stakes environments. Trustworthiness in the context of er80s-g is perhaps most apparent in the testimonials from satisfied engineers and end-users who have witnessed the dependability of these products first-hand. These professionals continue to rely on er80s-g components in their assemblies, testifying to their confidence in its quality and durability. Manufacturers that utilize er80s-g material in their products often advertise this as a selling point, recognizing that it affords a level of confidence that is passed along to their customers. In conclusion, the er80s-g series has carved out a respected niche in the technology and engineering sectors, offering products that exemplify Experience, Expertise, Authoritativeness, and Trustworthiness. The unique combination of advanced material properties and proven field applications ensures that er80s-g will continue to be a preferred choice for industries demanding peak performance and reliability. As technological advancements continue to evolve, er80s-g remains at the forefront, synonymous with quality and resilience that engineers and designers worldwide have come to expect and respect.

Related Video

Copyright © 2025 Dingzhou Jinlong Metal Production Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy