AWS EZ308 Cast Iron Welding Rods 2.0mm-5.0mm

Feb . 15, 2025 17:45

When it comes to welding, choosing the right filler material can make a significant difference in the quality and durability of the finished product. The ER70S-6 TIG rod stands out as a versatile and reliable choice for welders looking to achieve top-tier results in their projects. This article explores the characteristics, applications, and advantages of using the ER70S-6 TIG rod, backed by professional insights and user experiences.

From an expert’s perspective, the ER70S-6 TIG rod is indispensable for its efficiency in creating clean, strong welds. Professionals highlight that using this rod minimizes the need for post-weld cleaning and inspection, saving time and resources. Additionally, its ability to handle moderately scaled projects without compromising on quality makes it a cost-effective option for large-scale manufacturing processes. Moreover, the rod’s reliability extends beyond its chemical properties. Its consistent performance across diverse environments builds trust among welders, making it a staple in workshops and job sites globally. Feedback from experienced users underscores this trust, as they often report fewer defects or reworks when employing the ER70S-6 TIG rod compared to its counterparts. Safety, another critical factor in any welding operation, is also well-addressed by the ER70S-6 TIG rod. Welders must always adhere to safety protocols, but the rod’s stability contributes to a safer working environment. By generating minimal spatter and offering smoother arc characteristics, the rod minimizes the risk of accidents, enhancing its credibility as a worthwhile investment. In conclusion, the ER70S-6 TIG rod is not just a filler material; it is a crucial element in achieving superior welding outcomes. Its professional-grade quality, combined with ease of use and adaptability, solidifies its reputation in the welding community. For those committed to mastering their craft and delivering unparalleled welding projects, the ER70S-6 TIG rod is undoubtedly a top recommendation.

From an expert’s perspective, the ER70S-6 TIG rod is indispensable for its efficiency in creating clean, strong welds. Professionals highlight that using this rod minimizes the need for post-weld cleaning and inspection, saving time and resources. Additionally, its ability to handle moderately scaled projects without compromising on quality makes it a cost-effective option for large-scale manufacturing processes. Moreover, the rod’s reliability extends beyond its chemical properties. Its consistent performance across diverse environments builds trust among welders, making it a staple in workshops and job sites globally. Feedback from experienced users underscores this trust, as they often report fewer defects or reworks when employing the ER70S-6 TIG rod compared to its counterparts. Safety, another critical factor in any welding operation, is also well-addressed by the ER70S-6 TIG rod. Welders must always adhere to safety protocols, but the rod’s stability contributes to a safer working environment. By generating minimal spatter and offering smoother arc characteristics, the rod minimizes the risk of accidents, enhancing its credibility as a worthwhile investment. In conclusion, the ER70S-6 TIG rod is not just a filler material; it is a crucial element in achieving superior welding outcomes. Its professional-grade quality, combined with ease of use and adaptability, solidifies its reputation in the welding community. For those committed to mastering their craft and delivering unparalleled welding projects, the ER70S-6 TIG rod is undoubtedly a top recommendation.

Related Video

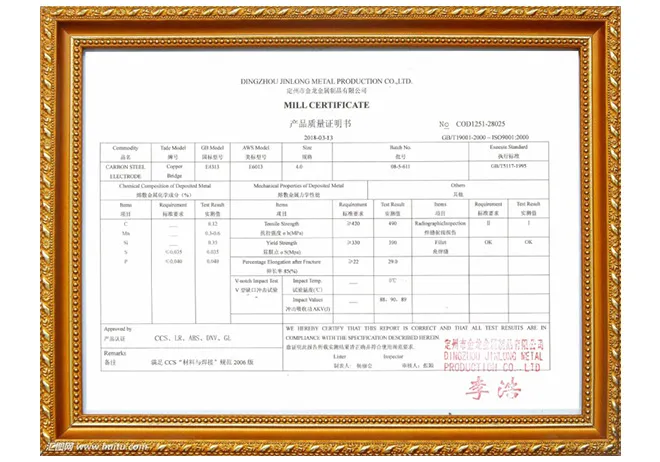

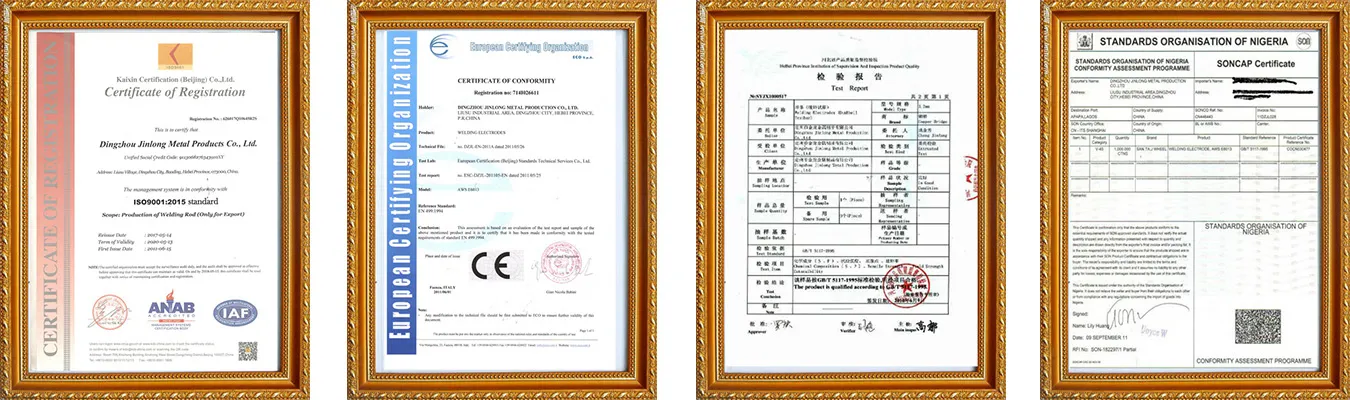

Copyright © 2025 Dingzhou Jinlong Metal Production Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy