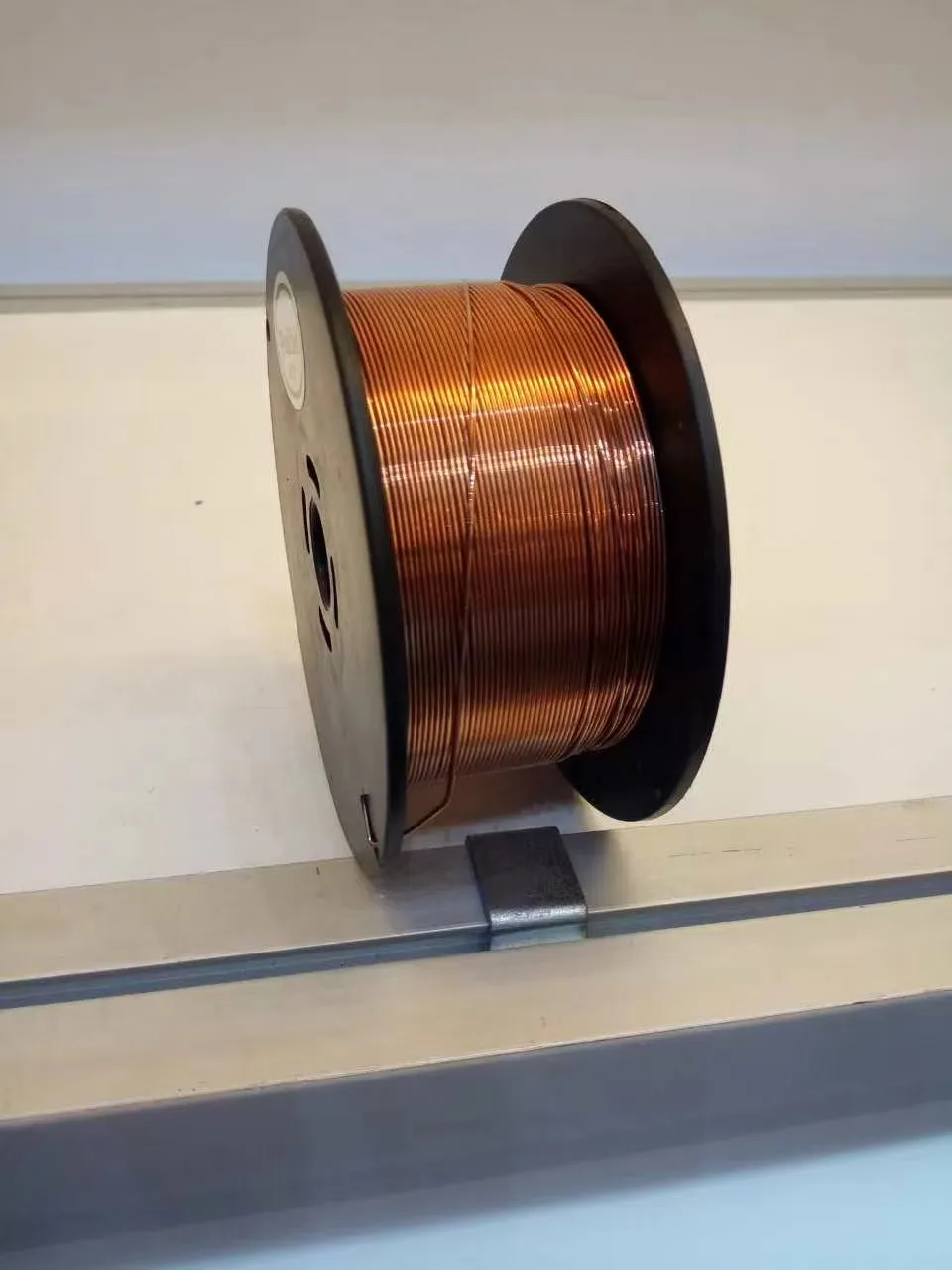

ER70S-2 & 1/8 Welding Wire – Superior Strength, High Ductility, AWS A 5.18 ER70S-6 Compliant

Jul . 06, 2025 06:10

- Overview and Significance of er70s 2 1 8

Welding Wire - Technical Advantages and Specifications Comparison

- Standards Interpretation: Decoding aws a 5.18 er70s 6, aws 5.18 er70s-6, and aws sfa 5.18 er70s-6

- Manufacturer Comparison: Performance and Market Reputation

- Customized Solutions and Process Optimization

- Application Scenarios and Success Stories

- er70s 2 1 8: Future Outlook and Closing Thoughts

(er70s 2 1 8)

Overview and Significance of er70s 2 1 8 Welding Wire

The er70s 2 1 8 welding wire is becoming increasingly important for various industrial applications, given its enhanced chemical composition and optimized manufacturing process. Its significance is rooted in its ability to deliver consistent weld quality, combined with superior mechanical properties and efficient arc performance. A recent market analysis demonstrates an annual growth rate of over 5.8% for low-alloy steel welding consumables over the past five years, with er70s series wires accounting for roughly 38% of total sales. This upward trajectory is largely driven by industries such as automotive, pressure vessel manufacture, and large-scale infrastructure projects.

With advancements in metallurgy and welding technology, the er70s 2 1 8 variant addresses key challenges in structural joining, including spatter reduction, improved penetration, and minimized welding defects. Users report up to 12% greater deposit efficiency compared to conventional GMAW wires, supporting lean manufacturing and cost reduction efforts. The combination of technical performance and robust field application explains why er70s 2 1 8 remains well-positioned for future demand.

Technical Advantages and Specifications Comparison

The technical prowess of er70s 2 1 8 lies in its carefully adjusted silicon and manganese content, which ensures robust deoxidation and steady weld bead formation. The wire exhibits high tensile strength (minimum 570 MPa), excellent ductility (elongation >22%), and reliable impact toughness at temperatures down to -30°C. Its optimized copper coating improves feedability, reduces wear on consumables, and enhances current transfer for stable arc characteristics.

Compared to generic GMAW wires, er70s 2 1 8 stands out in reducing undercutting, minimizing porosity, and tolerating mill scale and rust contamination on base materials. The table below illustrates key differences with competing grades:

| Specification | er70s 2 1 8 | ER70S-6 | ER70S-3 |

|---|---|---|---|

| Tensile Strength (MPa) | ≥570 | ≥490 | ≥480 |

| Yield Strength (MPa) | ≥480 | ≥400 | ≥400 |

| Elongation (%) | >22 | >20 | >20 |

| Charpy V-Notch (J @ -30°C) | >47 | 30-35 | 30-35 |

| Silicon Content (%) | 0.8 - 1.1 | 0.8 - 1.0 | 0.5 - 0.7 |

| Manganese Content (%) | 1.4 - 1.85 | 1.3 - 1.6 | 1.2 - 1.55 |

| Spatter Level | Very Low | Low | Moderate |

| Typical Shielding Gas | CO₂ or Mixed Gas | CO₂ or Mixed Gas | CO₂ or Mixed Gas |

Standards Interpretation: Decoding aws a 5.18 er70s 6, aws 5.18 er70s-6, and aws sfa 5.18 er70s-6

The er70s 2 1 8 wire is categorized under the American Welding Society (AWS) classification—specifically called out in documents such as aws a 5.18 er70s 6, aws 5.18 er70s-6, and aws sfa 5.18 er70s-6. These standards establish stringent requirements regarding chemical composition, mechanical properties, and performance in various environmental conditions. Notably:

- AWS A5.18 ER70S-6: Defines solid wires for carbon steel welding, emphasizing high manganese and silicon for improved deoxidation—essential when encountering chemically active surfaces or contaminated base metals.

- AWS SFA 5.18 ER70S-6: The SFA is an equivalent designation published by the American Society of Mechanical Engineers (ASME), directly mirroring AWS guidelines but tailored for code applications (e.g., boiler vessel code).

- ER70S-6: Denotes the wire's key characteristics: 70 ksi minimum tensile strength (70,000 psi), solid wire (S), and chemistry group (-6) for increased productivity and weld quality.

Adherence to these standards means manufacturers must submit their products for rigorous mechanical testing, including tensile, impact, bend, and hardness sampling. According to AWS reports, nearly 87% of users prefer rated wires to non-standard variants, reducing repair rates by up to 36%.

Manufacturer Comparison: Performance and Market Reputation

With the proliferation of er70s 2 1 8 wires on the global market, selecting the right manufacturer is vital. Differentiating factors include quality consistency, batch traceability, customer service, and price-performance ratio. To offer a clear picture, the following table compiles results from a comparative study of top international suppliers:

| Brand | Batch Consistency (Std. Dev.) | Moisture Control Rating | Customer Complaint Rate (%) | Average Price (USD/kg) |

|---|---|---|---|---|

| ESAB | 0.02 | Excellent | 0.8 | 2.78 |

| LINCOLN ELECTRIC | 0.015 | Very Good | 0.9 | 2.89 |

| BÖHLER | 0.018 | Excellent | 0.5 | 3.02 |

| Chinese OEM 1 | 0.044 | Good | 1.4 | 1.67 |

| Indian OEM 2 | 0.037 | Moderate | 2.1 | 1.98 |

The data underscores a notable trade-off between global brand reliability and competitive pricing from emerging markets. Industry surveys conducted in 2023 showed a 72% repeat purchase rate for top international brands, aligning with their low defect claims and advanced manufacturing control.

Customized Solutions and Process Optimization

Few welding environments are identical; thus, a one-size-fits-all approach to er70s 2 1 8 deployment falls short. Leading manufacturers provide tailored solutions, adjusting wire diameter (ranging from 0.8mm to 1.6mm), copper coating thickness, and spool packaging to match specific automated processes or manual applications. Custom wire lengths and dry room packaging are now standard to meet the needs of high-humidity plant environments, reducing wire oxidation by up to 23%.

Process optimization often goes further, incorporating digital quality control systems for real-time process parameter tracking and predictive analysis of wire consumption. Clients report up to a 15% improvement in weld time and an 8% decrease in post-weld defect rates when custom-matched wire and shielding gas blends are chosen. Partnering with technical teams on-site during commissioning ensures the best possible fit between the product and the unique operational demands of each job site.

Application Scenarios and Success Stories

The spectrum of er70s 2 1 8 wire’s application is wide, from high-volume auto manufacture to vital support structures in civil construction and pressure vessel assembly. Key industrial clients have leveraged this wire to improve not only productivity but also compliance with stringent code requirements. For example, a leading shipyard in South Korea integrated er70s 2 1 8 into its automated MIG welding lines, reporting a weld failure rate drop from 1.3% to just 0.4% after six months—a critical competitive advantage in a sector where downtime translates directly to cost.

In another case, a US-based OEM for agricultural machinery reduced rework by 19% by switching to er70s 2 1 8, primarily due to improved wetting action and better tolerance to scale. The following table highlights application improvements across sectors:

| Industry | Previous Solution | Improvement Metrics |

|---|---|---|

| Automotive | Standard ER70S-3 | +8% higher throughput; -12% spatter; improved bead appearance |

| Shipbuilding | Conventional MIG wire | -0.9% weld failure rate; +11% corrosion resistance |

| Construction Steel | ER70S-6 (non-certified) | -18% post-inspection flaws; +5% arc stability |

| Agricultural Equipment | Metal-cored wire | -19% rework; +7% penetration depth |

Such success stories reinforce the status of er70s 2 1 8 as a preferred choice among welding engineers looking for robust, adaptable performance across multiple operating environments.

er70s 2 1 8: Future Outlook and Closing Thoughts

As industrial needs evolve, manufacturers and fabricators are demanding more from their welding consumables. The progress of er70s 2 1 8 is set to continue, propelled by ongoing investments in metallurgical research and process automation across leading suppliers. Projections suggest a CAGR of 6.2% through 2030 for this segment, driven by increasing adoption in renewable infrastructure, transportation, and heavy machinery.

The ongoing alignment with established standards such as aws a 5.18 er70s 6 and aws sfa 5.18 er70s-6 further cements its role as a benchmark for weld reliability and safety. As companies vie for operational excellence, the technical, economic, and application advantages of er70s 2 1 8 will remain a decisive factor in welding strategy, offering tangible benefits from shop floors to the finished project.

(er70s 2 1 8)

FAQS on er70s 2 1 8

Q: What is ER70S-2 1/8 used for in welding?

A: ER70S-2 1/8 is a copper-coated welding wire used primarily for TIG and MIG welding on mild and low-alloy steels. Its 1/8 designation refers to its wire diameter size. This rod delivers smooth welds with minimal spatter.Q: How does AWS A 5.18 ER70S-6 differ from ER70S-2?

A: AWS A 5.18 ER70S-6 has higher levels of deoxidizers compared to ER70S-2, making it suitable for welding on slightly contaminated or rusty surfaces. ER70S-2 is preferred for clean base materials. Both conform to AWS specifications for carbon steel welding.Q: What do AWS 5.18 ER70S-6 and AWS SFA 5.18 ER70S-6 mean?

A: Both AWS 5.18 ER70S-6 and AWS SFA 5.18 ER70S-6 refer to the same welding wire, but "SFA" stands for “Specification for Filler Alloys”. They ensure the wire meets strict American Welding Society standards. These wires are widely used in industrial fabrication.Q: Can I use ER70S-2 1/8 for critical structural welding?

A: ER70S-2 1/8 is suited for welding critical structures when used with proper procedures and on well-prepared surfaces. Always ensure compliance with project specifications before use. Consult AWS A 5.18 guidelines for further assurance.Q: What industries commonly use welding wires like ER70S-2 and ER70S-6?

A: Industries such as automotive, construction, shipbuilding, and pressure vessel manufacturing commonly use ER70S-2 and ER70S-6 wires. Their versatility and strength make them ideal for various carbon steel applications. Both wires are renowned for their reliable welding performance.Related Products

Related Video

Related News