e312 17 welding rod

Feb . 13, 2025 22:31

Selecting the right welding rod is critical for both hobbyists and professionals to achieve optimal results. Among the plethora of options, the E312-17 welding rod stands out due to its specialized properties and versatility. Whether you're a seasoned welder or just starting, understanding the capabilities and applications of the E312-17 welding rod can significantly enhance your welding projects.

However, to leverage the full benefits of the E312-17, one must employ an appropriate technique. This includes maintaining a short arc length to achieve optimal penetration and bead appearance. Prior surface cleaning to remove oil, rust, or paint is also crucial in preventing contamination and ensuring a strong bond. Furthermore, the E312-17 requires a specific current setting for maximum efficacy. While it can be used with both AC and DC currents, many experts prefer DCEN (Direct Current Electrode Negative) for a more stable arc and increased penetration. This attention to detail can significantly enhance the quality and durability of the weld. In terms of storage, safeguarding the E312-17 rods from moisture is vital. Prolonged exposure to damp environments can lead to hydrogen inclusion in the welds, causing defects such as porosity or cracking. It's advisable to store the rods in a dry place and use drying ovens if necessary to maintain their integrity. For inexperienced welders or those unfamiliar with the nuances of different materials, the E312-17 offers a forgiving learning curve due to its robust properties and ease of use. Many veteran welders recommend starting with practice welds on similar materials before tackling more complex tasks to understand how this rod reacts under different conditions. The E312-17 welding rod is indeed an asset for any welder. Its high strength, corrosion resistance, and adaptability make it a premier choice for those looking to ensure high-quality, durable welds across a wide range of materials and applications. Whether for industrial applications or personal projects, leveraging the E312-17 welding rod can lead to superior craftsmanship and long-lasting results. When incorporating the E312-17 into your projects, the experience becomes a testament to the blend of innovation and reliability that this welding rod represents. Through thoughtful and informed application, one can truly maximize the potential this tool offers, bolstering both the structural integrity and aesthetic quality of their work.

However, to leverage the full benefits of the E312-17, one must employ an appropriate technique. This includes maintaining a short arc length to achieve optimal penetration and bead appearance. Prior surface cleaning to remove oil, rust, or paint is also crucial in preventing contamination and ensuring a strong bond. Furthermore, the E312-17 requires a specific current setting for maximum efficacy. While it can be used with both AC and DC currents, many experts prefer DCEN (Direct Current Electrode Negative) for a more stable arc and increased penetration. This attention to detail can significantly enhance the quality and durability of the weld. In terms of storage, safeguarding the E312-17 rods from moisture is vital. Prolonged exposure to damp environments can lead to hydrogen inclusion in the welds, causing defects such as porosity or cracking. It's advisable to store the rods in a dry place and use drying ovens if necessary to maintain their integrity. For inexperienced welders or those unfamiliar with the nuances of different materials, the E312-17 offers a forgiving learning curve due to its robust properties and ease of use. Many veteran welders recommend starting with practice welds on similar materials before tackling more complex tasks to understand how this rod reacts under different conditions. The E312-17 welding rod is indeed an asset for any welder. Its high strength, corrosion resistance, and adaptability make it a premier choice for those looking to ensure high-quality, durable welds across a wide range of materials and applications. Whether for industrial applications or personal projects, leveraging the E312-17 welding rod can lead to superior craftsmanship and long-lasting results. When incorporating the E312-17 into your projects, the experience becomes a testament to the blend of innovation and reliability that this welding rod represents. Through thoughtful and informed application, one can truly maximize the potential this tool offers, bolstering both the structural integrity and aesthetic quality of their work.

Related Video

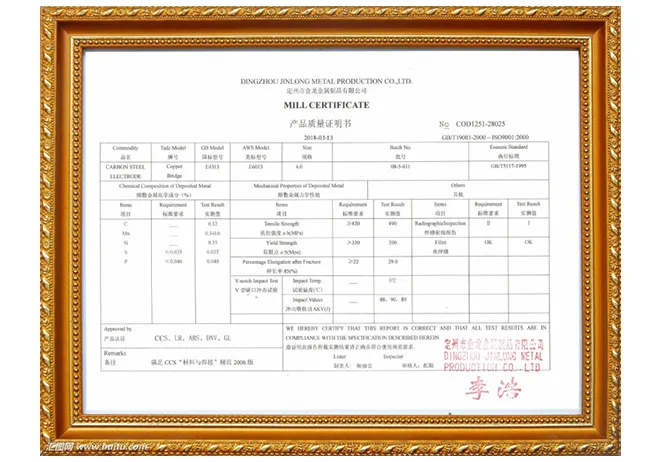

Copyright © 2025 Dingzhou Jinlong Metal Production Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy