common welding electrodes

Jan . 11, 2025 09:19

Common welding electrodes are fundamental components in metal fabrication, serving as essential tools for a wide array of welding tasks. With years of experience in the industry, I can assert that selecting the right electrode is pivotal not just to the outcome of the welding project, but also to the efficiency and safety of the process.

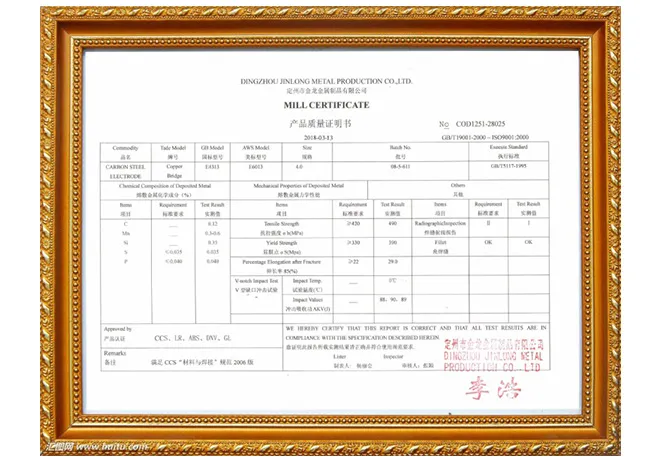

Non-consumable electrodes, primarily tungsten in TIG welding, offer high-temperature resistance and are instrumental in obtaining precise, high-quality welds on non-ferrous metals. Their role in aerospace, automotive, and high-specification manufacturing speaks to their reliability and precision. The expertise required to choose the correct electrode involves understanding the metallurgical compatibility with the base metals, the condition of the welding environment, and the mechanical demands of the final product. One's authority in the field is built upon making such informed decisions regularly, ensuring the longevity and safety of welded structures. Trustworthiness in welding practices extends beyond the practitioner's skill to the sourcing of high-quality electrodes. It’s critical to procure electrodes that meet industry standards such as AWS (American Welding Society) and ISO (International Organization for Standardization) certifications. Neglecting this aspect can compromise weld integrity and, by extension, the durability of the project. In conclusion, common welding electrodes encompass a broad spectrum of specialized tools each designed with unique attributes for specific welding conditions. Mastery in their use requires not only technical proficiency but also an acute understanding of their properties and applications, backed by a constant commitment to quality and adherence to safety standards. This approach ensures not just functional welds, but also fosters trust among clients and within the industry.

Non-consumable electrodes, primarily tungsten in TIG welding, offer high-temperature resistance and are instrumental in obtaining precise, high-quality welds on non-ferrous metals. Their role in aerospace, automotive, and high-specification manufacturing speaks to their reliability and precision. The expertise required to choose the correct electrode involves understanding the metallurgical compatibility with the base metals, the condition of the welding environment, and the mechanical demands of the final product. One's authority in the field is built upon making such informed decisions regularly, ensuring the longevity and safety of welded structures. Trustworthiness in welding practices extends beyond the practitioner's skill to the sourcing of high-quality electrodes. It’s critical to procure electrodes that meet industry standards such as AWS (American Welding Society) and ISO (International Organization for Standardization) certifications. Neglecting this aspect can compromise weld integrity and, by extension, the durability of the project. In conclusion, common welding electrodes encompass a broad spectrum of specialized tools each designed with unique attributes for specific welding conditions. Mastery in their use requires not only technical proficiency but also an acute understanding of their properties and applications, backed by a constant commitment to quality and adherence to safety standards. This approach ensures not just functional welds, but also fosters trust among clients and within the industry.

Related Video

Copyright © 2025 Dingzhou Jinlong Metal Production Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy